52

EN

Maintenance and inspection

WARNING

z

z

Before performing maintenance and inspection, always turn off the power.

z

z

Do not disassemble or alter the tool.

z

z

Use genuine parts.

CAUTION

z

z

For repair or part replacement, contact the retailer where you purchased the tool.

Repair requires special knowledge and skills. If repair is performed at a place other than a specialty store, the

tool may not demonstrate its full performance or it could lead to an accident or injury.

z

z

Request repair with the failed status kept intact.

When requesting a repair, do not throw away damaged parts. It could be important information for investigating

the failure cause so do not change the status.

Inspection locations

CAUTION

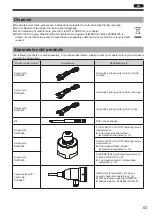

Cable

Failure to perform inspection could result in fire or electric shock.

z

z

Check if cables are damaged and if found, stop using the tool.

z

z

Do not store the cord by wrapping it around the main unit. If it is stored with the cable wrapped

around the main unit, immediately change the storage method.

Power plug

Failure to perform inspection could result in fire or electric shock.

z

z

Check for damage on the power plug. If damaged, stop using it.

z

z

Check if the power plug has dust or metallic material adhering to it. If attached, disconnect the

power plug and use a dry cloth to remove it.

z

z

Check that the power plug is property inserted into the outlet all the way to the base.

z

z

Check for play in the power plug and outlet.

Bit

z

z

Check for wear or damage on the bit end. Using the tool as is, the screw head could be damaged

or torque may not be transmitted. Replace with a new bit.

Main unit

z

z

Check for damage, cracks or breaks on the main unit.

z

z

Check the screws on the main unit. If screws are loose, tighten them.

Output torque

z

z

Use a combination of NITTO KOHKI's measuring devices to measure the output torque.

z

z

If the output torque value has changed, adjust the setting torque.

Screw fastening

time

z

z

Use the screw fastening time measurement function to check if the screw fastening time has not

changed.

z

z

The speed is a standard. It changes by the temperature of the tool, mechanical loss, and grease

conditions.

Care

z

z

If the main unit is stained, use a cloth soaked in soapy water and wrung out well to wipe off the

stain. The tool does not have a waterproof structure and if water enters inside, it could fail.

z

z

Because the main unit uses plastic, the following chemicals cannot be used.

Acetone, benzine, thinner, ketone, ether, trichlorethylene and other similar chemicals

Appendix

TV07783-1_DLV10C_en.indb 52

2017/06/27 17:41:42