44

EN

Resetting operation

If a problem occurs on the workpiece during screw tightening and the workpiece needs to be removed, you can reset

the operation.

CAUTION

z

z

For connection, use thick wire as much as possible. (AWG20 or more is recommended)

Resetting the screw fastening count

If a problem occurs during screw tightening, and the workpiece is removed and line-out occurs, you can reset the

series of operations.

Pressing and holding the controller [WORK RESET] button, or setting the WORK RESET input signal to ON for 1

second, returns to the screw fastening count of the operations channel setting.

You can perform reset even during the screw fastening confirmation time (No.17 OK-OUT-T) after completion of screw

tightening.

Restore and change the operations channel

When the “operations channel switching method” (No.1 CH-CHG) is set to “S-AUTO” or “C-AUTO”

When at screw fastening count setting, pressing and holding the controller [WORK RESET] button, or setting the

WORK RESET input signal to ON for 1 second, returns the screw fastening count of the 1 previous channel where the

count function was set to “ON”, to a 1 remainder state.

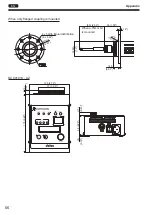

Example of reset and channel restore action

CH1

4

5

3

2

1

0

CH2

3

2

1

0

CH3

4

3

2

1

0

CH4

2

1

0

1

3

2

4

5

6

7

8

Screw count

(Count

number)

Operations flow

Reset

Channel return

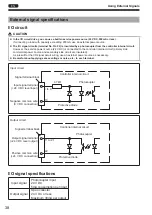

Reference the connection example of I/O signal (p. 40) for wiring.

Terminal

No.

Connected input signal

Connection example

8

WORK RESET

Connect the switch or PLC output (input the +24 V DC level)

10

Input signal negative common wire

Connect 0 V DC (connectable to terminal No.2)

When the “operations channel switching method” (No.1 CH-CHG) is set to “INPUT”

When an operations channel separate from the current channel is specified in the channel A/B input signal, pressing

and holding the controller [WORK RESET] button, or setting the WORK RESET input signal to ON for 1 second,

switches the operations channel. (p. 45)

Using External Signals

TV07783-1_DLV10C_en.indb 44

2017/06/27 17:41:41