51

EN

Symptoms

Location to investigate

Solution

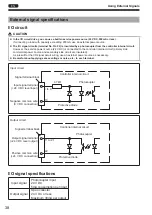

Input signal does not

react

Is there a mistake or error in cabling, or a

disconnection?

Is 0 V DC connected to the input signal

negative common wire (terminal No.10)?

Check the wiring. (p. 35)

Is the input signal (switch or PLC output

signal) firmly set to ON?

Check the external input signal.device being used.

Does the product setting and state match the

conditions receiving the input conditions?

Check each type of setting or state, and input a

signal at the suitable timing.

The output signal is

not output

Is there a mistake or error in cabling, or a

disconnection?

Is +24 V DC connected to the output signal

positive common wire (terminal No.22)?

Check the wiring. (p. 35)

Does the output signal specifications

(output circuit or output time, etc.) match

the input device or load specifications

detecting the output signal (input circuit or

reaction speed)?

Check the connecting external device or load.

Is the load in excess of the output signal

rating (30 V DC, 30mA), or the capacitive

load or inductive load, connected?

Since the output terminal (built-in photocoupler)

has the possibility of breaking down, do not

perform its connection.

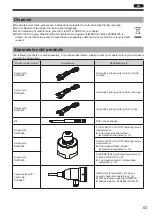

When you want to use

a 2-wire sensor

A 2-wire sensor cannot be used.

I want to connect

with the NPN signal

method machine

The signal method is PNP.

Use the signal converter, etc., to perform connection.

The service power

24 V DC

cannot be extracted

Is there a mistake or error in cabling, or a

disconnection?

Check the wiring. (p. 35)

Hast the output current capacity (200mA)

been exceeded for use?

Do not exceed the output current capacity for use.

If the output current capacity is not sufficient, use

a separate external power source.

Buzzer sound is small

Is the buzzer sound setting too small?

Set the “buzzer sound volume” (No.22 BZ-

VOLUME) larger.

If the sound is still too small, attach a buzzer or

lamp to the output signal. (p. 34)

LCD display is difficult

to read

Is the back light (yellow-green color)

lighted up?

Set the “back light” (No.24 BACK LIGHT) to “ON”.

The electric

screwdriver gets hot

Is the ON (rotation) time of the electric

screwdriver too long?

Or is the OFF time too short?

Review the operation time.

The rated operating time is 0.5 sec. ON/3.5 sec.

OFF.

Aim at 15 screws or less for the screw tightening

per minute. (p. 8)

Is the tapping screw tightened?

If the load is high during tapping screws and

other screw tightening, the electric screwdriver

temperature will also tend to become higher.

Review the operations time, and lengthen the

OFF (stop) time.

Is the rated voltage input?

Check the power source voltage, and input the

rated voltage.

Does it become so hot that it cannot be

touched?

If so much heat is generated as to be too hot

to touch, even if the screw fastening load is not

heavy, and the rated operation time is maintained,

a failure is suspected.

Cannot be extracted

from the setting mode

Is the “operations channel switching

method” (No.1 CH-CHG) set to “S-AUTO” or

“C-AUTO”, and the “count function” (No.11

COUNT-FNC) set to all channels “OFF”?

Set any of the channel “count function” (No.11

COUNT-FNC) to “ON”. (p. 31)

An error message is

displayed on the LCD

Check the error message (p. 47), and re-insert the power.

The setting conditions

are unknown

It does not activate as

expected

Did you make a note of the settings?

Review each of the settings. (p. 25)

To initialize the setting values, execute “setting

value initialization” (No.25 SETTING RESET).

(p. 24)

After the setting, write down the settings on the

setting memo. (p. 63)

TV07783-1_DLV10C_en.indb 51

2017/06/27 17:41:42