Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

21

4. Align one modesty panel to the

corner leg and worksurface

mounting holes. If optional

horizontal wireways are to be

installed to unit, place wireways

between the mounting flange

of the of the modesty panel and

the worksurface, aligning the

mounting holes as illustrated.

Insert two #10 x ½” screws

through the modesty panel

and into the corner leg. Attach

modesty panel (through optional

horizontal wireways if applicable)

to worksurface with two

#12 x 1” screws. Do not tighten

at this time. Repeat this step for

second modesty panel. Tighten

all screws attaching the corner

leg and the modesty panels

(Figure 2).

Note:

If assembling transitional

corner keyboard unit see

instructions A through D and then

continue on to steps 5 though

9. If assembling transitional unit

without keyboard, skip now to

steps 5 through 9.

Keyboard Pad Only

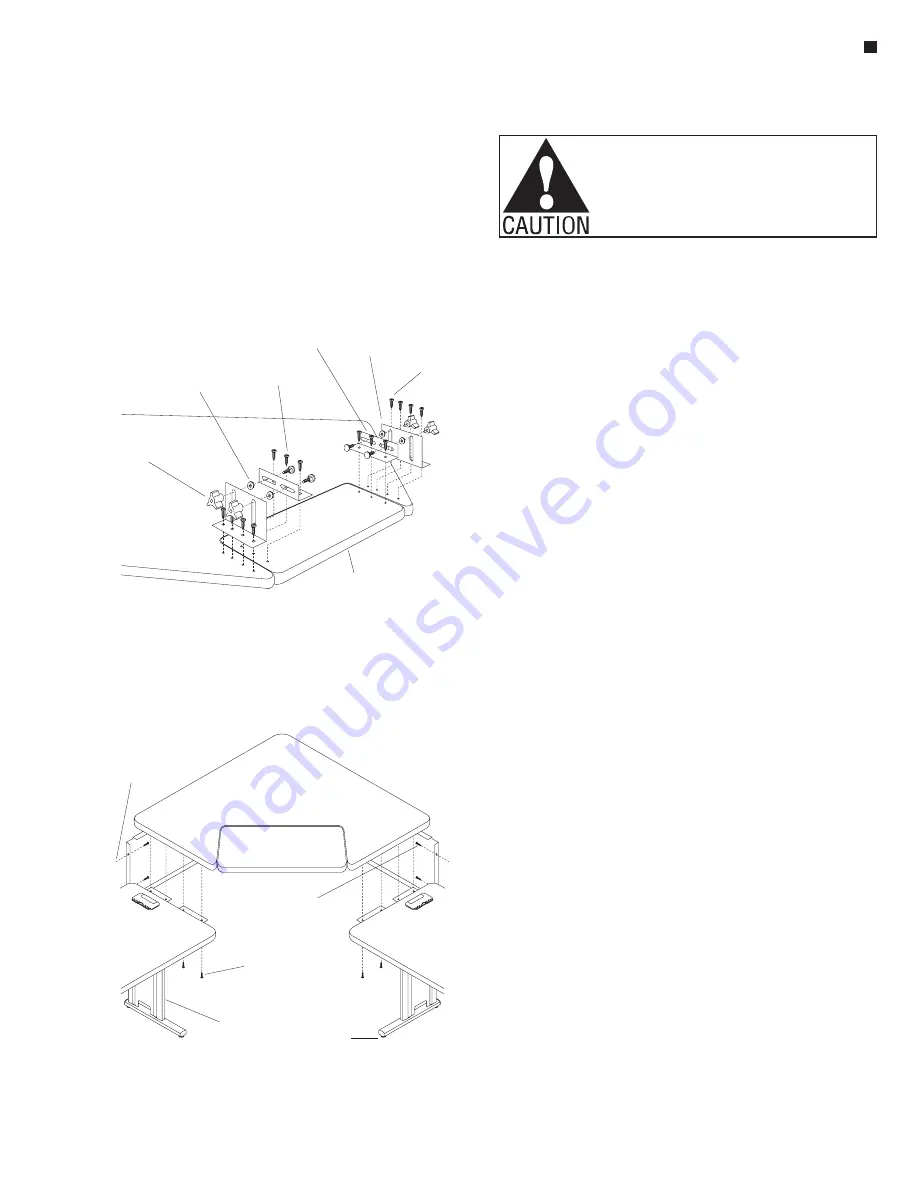

A. Attach two small brackets to the

keyboard pad by first aligning

holes in the keyboard pad. Insert

six #12 x 1” screws, three per

small bracket, but do not tighten

completely (Figure 3).

B. Attach the two large brackets

to the pre-drilled holes in

worksurface with four #12 x 1”

screws per bracket, but do not

tighten completely (Figure 3).

C. Assemble and tighten four

adjustment knobs, connecting the

small brackets on the keyboard

pad to the large brackets on the

corner worksurface. These knobs

consist of carriage bolt. washer

and tightening knob for each set

(Figure 3).

D. Center the keyboard pad to the

opening in the worksurface.

Tighten all bracket screws

completely, starting with the large

brackets on the worksurface.

(Figure 3).

5. Orient the primary and return

worksurfaces as illustrated so

they are in position to assemble

the transitional unit in step 7

(Figure 4).

6. Carefully turn the transitional

assembly right side up and set

it onto the splice plates of the

primary and return worksurface.

Align the mounting holes of the

splice plats with pre-drilled holes

in transitional worksurface. Insert

two #12 x 1” screws through each

splice plate into the transitional

worksurface and tighten

(Figure 4).

Note:

Transitional legs can

be identified by their shorter,

floor-level foot, for less restricted

movement.

7. Attach both modesty panels to the

adjoining transitional legs of the

primary and return worksurfaces

with two #10 x ½” screws each

(Figure 4).

8. Tighten all remaining screws in

the worksurface assembly. Level

the worksurfaces by turning the

adjustable glides either in or

out. The jambnuts between the

adjustable glides and the bottom

of the leg sets must be tightened

up against the bottom of the leg

to secure the adjustable glides

(Figure 4).

Note:

In a “step down”

installation, use a Z-bracket (not

shown) instead of a splice plate.

The Z-brackets are installed in the

same manner as splice plates.

WorkZone

®

Transitional Worksurface - Keyboard Pad, Square & Rectangle & Corner

Assembly Instructions

4. Align one modesty panel to the corner

leg and worksurface mounting holes. If

optional horizontal wireways are to be

installed to unit, place wireways between

the mounting flange of the of the modesty

panel and the worksurface, aligning the

mounting holes as illustrated. Insert two

#10 x ½” screws through the modesty

panel and into the corner leg. Attach

modesty panel (through optional

horizontal wireways if applicable) to

worksurface with two #12 x 1” screws.

Do not tighten at this time. Repeat this

step for second modesty panel. Tighten

all screws attaching the corner leg and

the modesty panels (Figure 2).

If assembling stand alone corner

keyboard unit see instructions A through

D and then continue on to steps 5 though

9. If assembling stand alone unit without

keyboard, skip now to steps 5 through 9.

A. Attach two small brackets to the

keyboard pad by first aligning holes in the

keyboard pad. Insert six #12 x 1”

screws, three per small bracket, but do

not tighten completely (Figure 2).

B. Attach the two large bracekts to the

pre-drilled holes in worksurface with four

#12 x 1” screws per bracket, but do not

tighten completely (Figure 2).

C. Assemble and tighten four adjustment

knobs, connecting the small brackets on

the keyboard pad to the large brackets on

the corner worksurface. These knobs

consist of carriage bolt. washer and

tightening knob for each set (Figure 2).

D. Center the keyboard pad to the

opening in the worksurface. Tighten all

bracket screws completely, starting with

the large brackets on the worksurface.

(Figure 3).

Note:

Keyboard Pad Only

5. Orient the primary and return

worksurfaces as illustrated so they are in

position to assemble the transitional unit

in step 7 (Figure 4).

6. Carefully turn the transitional assembly

right side up and carefully set it onto the

splice plates of the primary and return

worksurface. Align the mounting holes of

the splice plats with pre-drilled holes in

transitional worksurface. Insert two

#12 x 1” screws through each splice

plate into the transitional worksurface

and tighten (Figure 4).

Transitional legs can be identified

by their shorter, floor-level foot, for less

restricted movement.

7. Attach both modesty panels to the

adjoining transitional legs of the primary

and return worksurfaces with two

#10 x ½” screws each (Figure 4).

8. Tighten all remaining screws in the

worksurface assembly. Level the

worksurfaces by turning the adjustable

glides either in or out. The jambnuts

between the adjustable glides and the

bottom of the leg sets must be tightened

up against the bottom of the leg to

secure the adjustable glides (Figure 2).

In a “step down” installation, use a

Z-bracket (not shown) instead of a splice

plate. The Z-brackets are installed in the

same manner as splice plates.

Note:

Note:

#12 x 1"

screw

large

bracket

small

bracket

#12 x 1”

screw

washer

adjustment

knob

corner

worksurface

Figure 3

transitional

leg set

primary

worksurface

return

worksurface

#12 x 1"

screw

#10 x / "

screw

1

2

attach to

transitional

leg

Figure 4

WorkZone Transitional Worksurface

Figure 3

Figure 4

keyboard pad

adjustable

glide