Green Heating Technology

9

tion in force prescribe its positioning, the temperature limits within the user can adjust it and the

periods of heating.

Remark:

an optional, original Remote Control kit is available (see "Remote Control Kit" on page 47

for information) or a cutting-edge chronotermostat kit featuring weekly programming of various

temperature levels and other special functions. Also

wireless

and

GSM controlled

versions are

available.

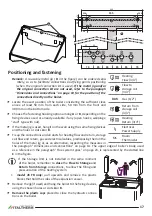

Faucet or valve for filling the system:

a device must be foreseen, by the installer, to fill and pressurize

the system. Basically it is a faucet or valve, possibly near the boiler, connected to the fresh water

source. If, however, the plant is to be filled with heat exchanger fluid (eg anti-freeze solution) instead

of water, it must be equipped with a hose plug or other fitting suitable for supply, under pressure, the

system with such liquid (see also "Heating system filling and pressuring" on page 19).

Commands related to Domestic Hot Water

By the point of view of the domestic hot water, the boiler is designed to be implemented in a system

with a domestic hot water storage tank, usually combined with a solar system, that on its turn is nor-

mally equipped with suitable commands and indicators to manage the hot water sent to the users.

Only when a storage temperature probe, connected directly to the boiler, is present, the setting of the

DHW temperature, by means of the knob

, determinates the temperature to which the water in the

storage is heated*. If no temperature adjustment devices, downstream the storage, are installed, the

knob

adjusts the temperature of the water to the user. Otherwise, this setting will affect only the

maximum available temperature* and on the "duration" of the availability of hot water.

(* in absence of

heat input from external systems, e.g. solar).

More complex systems can manage directly both the storage tem

-

perature (by forcing the boiler to heat the storage, if required) and the temperature to the user.

See the

documentation supplied with the system

or ask for information to the installer or to the designer

�

A high storage temperature increase the limestone scale of the storage.

Also gas consumption

depends on the set temperature, aside from the quality of the storage thermal insulation.

Remark:

Because of

the thermal dissipation along the pipings, it could be necessary a certain time

before the temperature of the water out of the faucet gets stabilized.

Typical use

Preliminary operations

f

Be sure the gas cock

3

is opened�

f

Be sure the boiler is electrically powered and set in

OFF

: only

has to be displayed on the screen�

f

Make sure, by the gauge

1

that the

cold-system temperature is always within 0.5 and 1.5 Bar (opti

-

mal: 1÷1.5 Bar)

. When the pressure

drops below 0.5 Bar

, the boiler

stops working

. In this case, use

the system filling device up to restore, on the gauge, the pressure

of 1.0 Bar (max 1.5 Bar)

�

The system pressure raises with the temperature: a too high initial cold-system pressure could

lead to

water drain from the 3 Bar safety valve

after the system heating-up.

Содержание CITY GLASS 20 FR

Страница 37: ...Green Heating Technology 37 Notes ...

Страница 48: ...Green Heating Technology 48 Notes ...

Страница 49: ...Green Heating Technology 49 Notes ...