• When it is determined necessary based on the predicted value for temperature inside the machine (according to the usage

environment and continuous print state).

Control description

Color displacement correction control based on patch pattern

1. The Main Controller PCB forms the patch pattern of each color on the ITB.

2. The DC Controller PCB scans this patch pattern using the Registration Patch Sensor Unit (Front) (UN31) and

Registration Patch Sensor Unit (Rear) (UN32) to detect the amount of color displacement compared to the reference

color (Y).

3. Based on the above-mentioned detection result, the DC Controller PCB executes correction according to the degree of

color displacement.

Color displacement correction control based on temperature prediction

1. The degree of color displacement is measured based on the operating condition (mainly temperature).

2. The exposure timing for M/C/Bk is adjusted based on Y.

3. Color displacement correction is performed based on the above patch patterns.

Type of control

Correction description

Correction in horizon-

tal scanning direction

Write start correction

Write-start timing in horizontal scanning direction is changed.

Entire-area magnification ratio

correction

Pixels in horizontal scanning direction is increased/reduced (at the

both edges of the image)

Correction in vertical

scanning direction

Write start correction

Write-start timing in vertical scanning direction is changed.

Image skew correction

Image data is corrected.

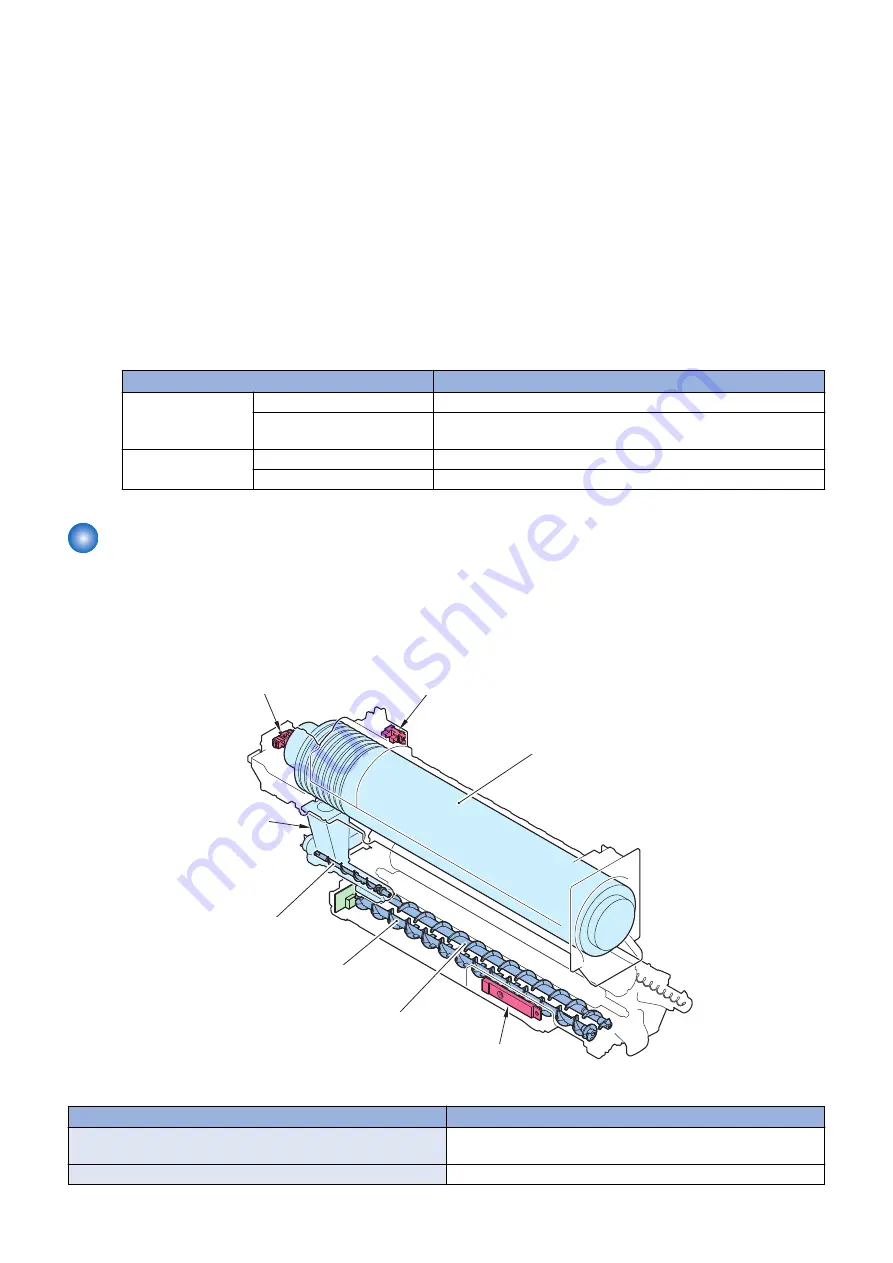

Toner Supply Assembly

■ Overview

Toner is supplied from the Toner Container to the Developing Assembly. The toner level in the Toner Container is detected at

the same time.

Hopper Unit

Bottle Rotation Sensor

(Y,M,C,Bk)

(PS6,7,8,9)

ATR Sensor

(Y,M,C,Bk)

(UN34,35,36,37)

Toner Container

Toner Feed Screw

Developer Feed Screw B

Developer Feed Screw A

Toner Log Connector

(Y,M,C,Bk)

(UN38,39,40,41)

Parts name

Role

Hopper Unit

Toner is supplied from the Toner Container to the Developing As-

sembly.

Toner Feed Screw

Toner is supplied from the Hopper Unit to the Developing Assembly.

2. Technology

67

Содержание imageRUNNER ADVANCE C255 Series

Страница 1: ...Revision 2 0 imageRUNNER ADVANCE C355 C255 Series Service Manual ...

Страница 17: ...Product Overview 1 Product Lineup 7 Option 8 Features 11 Specifications 14 Parts Name 18 ...

Страница 127: ...Periodical Service 3 Periodically Replacement Parts 117 Consumable parts 118 ...

Страница 128: ...Periodically Replacement Parts There are no periodically replacement parts in this machine 3 Periodical Service 117 ...

Страница 154: ...4 Remove the Screws 5x 5 Remove the Rear Cover 1 4 Parts Replacement and Cleaning 143 ...

Страница 213: ...3 Remove the Fan Guide 1 1 Screw 2 1 Boss 3 3 Hooks 4 1 1x 2 3 4 4 4 Parts Replacement and Cleaning 202 ...

Страница 215: ...5 Remove the Fixing Harness Guide 1 1 Boss 2 2 Hooks 3 1 2 3 4 Parts Replacement and Cleaning 204 ...

Страница 257: ...1 Free the Harness 1 Harness Guide A 1x 1 A 4 Parts Replacement and Cleaning 246 ...

Страница 269: ...7 Remove the Fixing Inlet Guide 1 1 Claw 2 5 Hooks 3 1 2 3 1x 4 Parts Replacement and Cleaning 258 ...

Страница 317: ...Adjustment 5 Actions at Parts Replacement 307 Original Exposure System 313 Pickup Feed System 314 ...

Страница 326: ...2 Check the value of the scale on the Adjustment Plate 3 Loosen the Fixation Screw 1x 5 Adjustment 315 ...

Страница 376: ...Error Jam Alarm 7 Overview 366 EError Code 369 Jam Code 457 Alarm Code 464 ...

Страница 469: ...Host Machine Cassette PS12 PS11 PS01 PS04 PS05 PS14 PS10 PS101 7 Error Jam Alarm 458 ...

Страница 490: ...85 0005 For R D A Operation B Cause C Remedy 7 Error Jam Alarm 479 ...

Страница 495: ... i Press the button to display the screen showing the locations of electrical components 8 Service Mode 484 ...

Страница 882: ...2 CAUTION Do not install the IC Card Reader Support Plate in the opposite direction 4x TP M3x6 3 9 Installation 871 ...

Страница 890: ...4 4x TP M3x6 5 3x 6 2x TP M3x6 7 8 9 Installation 879 ...

Страница 891: ...9 1x 10 1x 11 2x 12 4x 13 9 Installation 880 ...

Страница 900: ...7 8 9 NOTE Proceed to step 13 In the case of a Card Reader manufactured by TOPPAN 10 9 Installation 889 ...

Страница 901: ...11 12 1x 13 NOTE Use the screw removed in steps 3 1x 14 NOTE Be sure to wind it counterclockwise 1x 9 Installation 890 ...

Страница 902: ...15 Binding 1x 1x 1x 16 CAUTION Be sure to align the corners with the indexes 9 Installation 891 ...

Страница 903: ...17 9 Installation 892 ...

Страница 913: ...2 3 RS Tightening M4x10 Boss 1x 1x 4 CAUTION Be sure that the core is inside the Edge Saddle 1x 1x 9 Installation 902 ...

Страница 914: ...5 6 2x Screw w washer M3x14 7 4x TP M3x6 9 Installation 903 ...

Страница 923: ...3 2x 4 Short 1x 5 1x NOTE The removed screw will be used in step 7 6 1x 9 Installation 912 ...

Страница 927: ... In the case of printer model having Cassette Pedestal 2x 5x 1x 1x 2x 2x 2x 1x 1x 9 Installation 916 ...

Страница 929: ...3 4 4x 5 CAUTION Be sure to place 5 or more sheets of paper to prevent damage 6 7 8 1x 9 Installation 918 ...

Страница 930: ...9 10 11 1x 12 13 9 Installation 919 ...

Страница 931: ...14 2x 15 16 2x 17 6x 18 4x 9 Installation 920 ...

Страница 932: ... Installing the NFC kit C1 1 1x 2 1x 3 TP M3x4 1x 9 Installation 921 ...

Страница 934: ...2 6x 3 2x 4 NOTE Be sure to pay attention to the direction of the cover 5 2x 6 9 Installation 923 ...

Страница 935: ...7 8 1x 9 10 11 1x 9 Installation 924 ...