9

Table 6: Maximum Flue Temperature for Various Vent Materials

Vent Material

Maximum Flue Temperature [

o

F]

PVC

149

CPVC

194

PPE

230

AL29-4C

300+, limited only by rating of seals

316L Stainless Steel

300+, limited only by rating of seals

Stack temperature is typically between 15-30

o

F above inlet

water temperature depending on model size and firing rate.

Air Inlet (Supply Air or Fresh Air) Piping

•

PVC

•

CPVC (Chlorinated Polyvinyl Chloride)

•

PPE (Polypropylene)

•

ABS (Acrylonitrile-Butadiene-Styrene)

•

Single wall, Galvanized

•

Single wall, Stainless steel

•

Single wall, Aluminium

Single wall air inlet pipes are to be insulated 5 feet from the

wall toward the interior of the building to minimize external

sweating.

The following air intake options shall be utilized:

•

Outside air sealed direct (vertical or horizontal)

•

Outside air ducted to jacket flange

•

Indoor Air

NOTE

For wall hung units that are installed outdoors the bottom of

the unit must be at least 36” above ground or 12” above

normal snow levels.

NOTE

Sealed combustion is required when DynaMax HS is placed

in a space with other fan-assisted appliances.

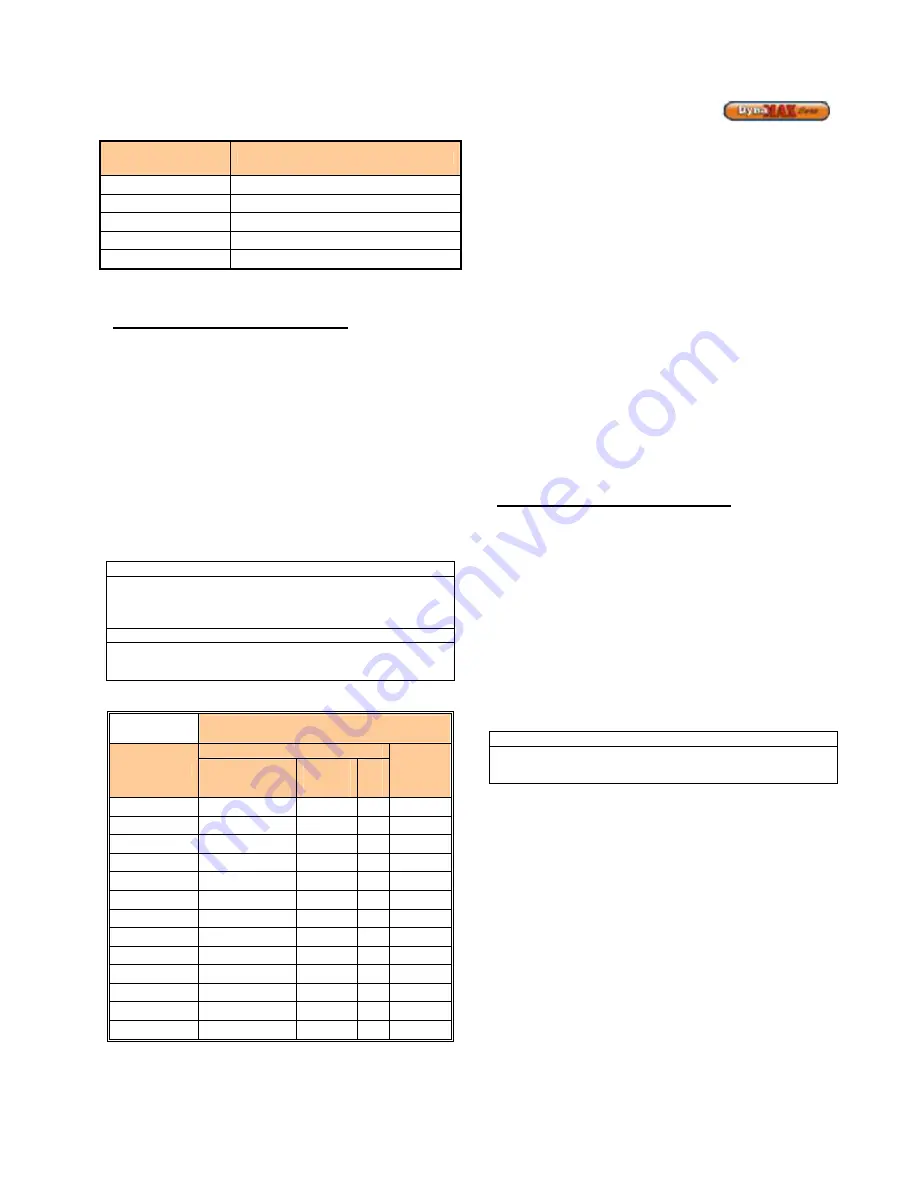

Table 7: Required Vent and Air Inlet Diameters

Equivalent Length of Vent & Air Intake Pipes

at Recommended Diameter*

Model

Category IV

Category

II

Over 25' and up

to 100'

Over 15'

and up

to 25'

Up

to

15'

80

3"

3"

2"

-

100

3"

3"

2"

-

150

3"

3"

2"

-

200

3"

3"

2"

-

210

3"

3"

2"

4”

250

3"

3"

2"

-

260

3"

3"

2"

4”

299

4"

3"

3"

5”

399

4"

3"

3"

5”

500

4"

3"

3"

6”

600

4”

3”

3”

6”

700

4” (Air), 5” (Vent)

4”

4”

7”

800

5” (Air), 6” (Vent)

5”

5”

7”

* Consult factory for recommendations applicable to venting

combinations not shown above.

2.3

CATEGORY II VENTING

A category II appliance may be combined into a common

negative pressure venting system designed to ASHRAE

requirements using a proven vent sizing program. Vent

designs are to be certified by a qualified professional

designer acceptable to the authority having jurisdiction.

1)

The DynaMax HS Floor Mount boiler may be vented as a

Category II appliance using sealed vent suitable for a

condensing appliance.

2.3.1

Approved Venting Materials Category II

1) PVC and CPVC Schedule 40 approved to ULC S636.

2) Manufactured prefabricated UL/ULC listed vent of AL29-

4C or 316L stainless steel. Use of 316L is limited to use

where there is no possibility of contaminants in the air

such as refrigerants, chlorine etc.

3) PVC-DWV approved to comply with ANSI/ASTM D2665

(US Jurisdictions ONLY when permitted).

4) PVC Schedule 40 approved to comply with ANSI/ASTM

D1785. (US Jurisdictions ONLY when permitted)

5) CPVC Schedule 40 approved to comply with

ANSI/ASTM F441. (US Jurisdictions ONLY when

permitted).

6) Polypropylene approved to comply with ULC S636

Air Inlet (Supply Air or Fresh Air) Piping

•

PVC

•

CPVC (Chlorinated Polyvinyl Chloride)

•

ABS (Acrylonitrile-Butadiene-Styrene)

•

PPE (Polypropylene)

•

Single wall, Galvanized

•

Single wall, Stainless steel

•

Single wall, Aluminium

Single wall air inlet pipes are to be insulated 5 feet from the

wall toward the interior of the building to minimize external

sweating.

The following air intake options shall be utilized:

•

Outside air sealed direct (vertical or horizontal)

•

Outside air ducted to jacket flange

•

Indoor Air

NOTE

Sealed combustion is required when DynaMax HS is placed

in a space with other fan-assisted appliances.

2.4

COMBINED COMBUSTION AIR INLET

To avoid the possibility of nuisance lockouts in cold climates

install DynaMax HS appliances may be installed with a

combined combustion air inlet.

The combined combustion air inlet pipe sizing can be

calculated using the method shown below:

Equivalent pipe diameter = Sq Root [(d

1

)

2

+ (d

2

)

2

+ (d

3

)

2

+ …

+ (d

n

)

2

], where d

n

= individual pipe diameter

•

Example: Find the equivalent pipe diameter of three

air inlet pipes, 3” (7.6cm), 3” (7.6cm) and 4”

(10.2cm)

Equivalent pipe diameter = Sq Root[(3)

2

+ (3)

2

+

(4)

2

] = Sq Root(34) = 5.8”, select 6” (15.3cm)

equivalent diameter pipe.

Содержание DynaMax DMH081

Страница 2: ......

Страница 12: ...7 Figure 5 DynaMax HS Wall Hung Service Clearances Figure 6 DynaMax HS Floor Mount Service Clearances...

Страница 68: ...65 PART 14 EXPLODED VIEW PARTS LIST DYNAMAX HS WALL HUNG...

Страница 69: ...66 DYNAMAX HS FLOOR MOUNT...

Страница 76: ...73 PART 15 ELECTRICAL DIAGRAMS 15 1 DM 80 299 INTERNAL WIRING DIAGRAM...

Страница 77: ...74 15 2 DM 399 800 INTERNAL WIRING DIAGRAM...

Страница 78: ...75...