53

on an annual basis. An appliance installed in a dust or dirt

contaminated environment will require inspection and

cleaning on a more frequent schedule. The fan assisted

combustion process may force airborne dust and dirt

contaminants, contained in the combustion air, into the

burner.

With

sustained

operation,

non-combustible

contaminants may reduce burner port area, reduce burner

input or cause non-warrantable damage to the burner.

Never operate this appliance during construction.

Airborne contaminants such as dust, dirt, concrete dust or

dry wall dust can be drawn into the burner with the

combustion air and block the burner port area.

9.7.1

Burner Removal and Cleaning

Access to the burner will require the following steps:

•

Turn off main electrical power to the appliance.

•

Turn off main manual gas shutoff to the

appliance

•

Remove the front cover.

•

Disconnect the gas supply to the fan inlet.

•

Disconnect the fan motor power wires at the

harness.

•

Remove the direct spark igniter and the flame

sensor.

•

Remove the T-25 screws holding the front burner

flange in place to gain access to the burner.

•

The burner can now be pulled horizontally out of

the heat exchanger cavity.

•

Use care to prevent damage to the knitted metal

fiber of the burner surface.

•

Wash the burner with water, such as a garden

hose. Never wipe or brush the surface of the

burner.

•

For optimal results immerse the burner port area

in a solution of dishwashing detergent and hot

water. DO NOT use chlorine based solvents or

cleaning agents on the burner. Allow the burner to

remain in the solution for a short period of time to

remove, dust, dirt and oil or grease laden

contaminants.

•

Rinse the burner thoroughly with clean water to

remove any residue from the detergent cleaner

•

The burner should be air dried after removal from

the cleaning solution and rinsing.

•

Check all gaskets and replace as necessary.

Gaskets affected by heat will not reseal properly

and must be replaced.

•

Replace the burner in the reverse order that it was

removed.

NOTE

When the combustion air fan is removed for any reason,

the inlet to the burner must be covered to prevent foreign

objects from falling into the burner. Always look inside the

burner to check for dents. Do not place a burner back into

operation if the inner distribution screen has been dented

during the service operation, call the factory for

recommendations. Use care when removing and handling

the burner, Sharp objects or impact may damage or tear

the metal fiber surface rendering the burner unfit for

service.

9.8

REMOVAL OF COMBUSTION CHAMBER

LINING

The combustion chamber insulation in this appliance

contains ceramic fiber material. Ceramic fibers can be

converted to cristobalite in very high temperature

applications. The International Agency for Research on

Cancer (IARC) has concluded, “Crystalline silica in this

form of quartz of cristobalite from occupational sources is

carcinogenic to humans (Group 1)”. Normal operating

temperatures in this appliance are below the level to

convert ceramic fibers to cristobalite. Abnormal operating

conditions would have to be created to convert the ceramic

fibers in this appliance to cristobalite.

The ceramic fiber material used in this appliance is an

irritant; when handling or replacing the ceramic materials it

is advisable that the installer follow these safety guidelines.

•

Avoid breathing dust and contact with skin and

eyes.

o

Use NIOSH certified dust respirator

(N95). This type of respirator is based on

the OSHA requirements for cristobalite at

the

time

this

documentation

was

written.Other types of respirators may be

needed depending on the job site

conditions.

Current

NIOSH

recommendations can be found on the

NIOSH

website

at

http://www.cdc.gov/niosh/homepage.html

.

NIOSH

approved

respirators,

manufacturers, and phone numbers are

also listed on this website.

o

Wear long-sleeved, loose fitting clothing,

gloves, and eye protection

•

Apply enough water to the combustion chamber

lining to prevent airborne dust.

•

Remove the combustion chamber lining from the

water heater and place it in a plastic bag for

disposal.

•

Wash potentially contaminated clothes separately

from other clothing. Rinse clothes washer

thoroughly.

NIOSH stated First Aid

•

Eye: Irrigate immediately

•

Breathing: Fresh air

9.9

COMBUSTION AND VENTILATION AIR

Check frequently to be sure that the flow of combustion air

to the appliance is not obstructed. Unless air is piped

directly to the heater combustion air must be provided to

the mechanical room with openings sized per the

requirements of the current B149 or National Fuel Gas

Code. The DynaMax HS is setup to allow outdoor

combustion air to be connected directly to the appliance. It

is highly recommended that combustion air be connected

directly to the appliance. For installations in a common

boiler room with atmospheric appliances or if there is the

possibility of negative pressure in the boiler room, the air

inlet must be piped directly to the DynaMax HS.

Содержание DynaMax DMH081

Страница 2: ......

Страница 12: ...7 Figure 5 DynaMax HS Wall Hung Service Clearances Figure 6 DynaMax HS Floor Mount Service Clearances...

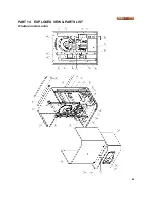

Страница 68: ...65 PART 14 EXPLODED VIEW PARTS LIST DYNAMAX HS WALL HUNG...

Страница 69: ...66 DYNAMAX HS FLOOR MOUNT...

Страница 76: ...73 PART 15 ELECTRICAL DIAGRAMS 15 1 DM 80 299 INTERNAL WIRING DIAGRAM...

Страница 77: ...74 15 2 DM 399 800 INTERNAL WIRING DIAGRAM...

Страница 78: ...75...