700 NDIR Analyzer

6-20-2017

31

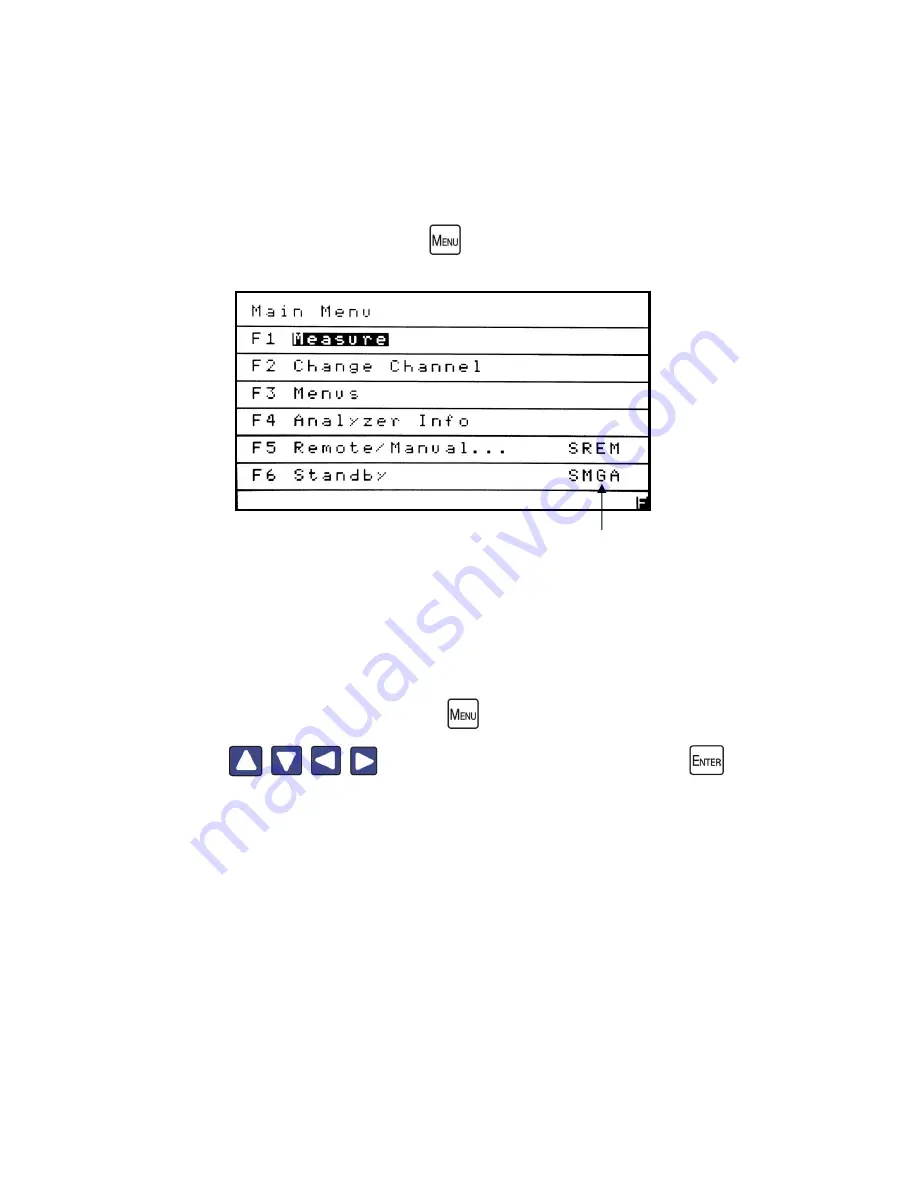

Main Menu

The Main Menu lists the setup and maintenance functions menus for the 700

NDIR/O

2

analyzer.

All software functions of the Series 700 NDIR/O

2

Analyzer can be

reached via the menu above from the Main Menu screen.

Operation starts by pressing the Menu key

to bring up the Main Menu. Use the

Arrow keys

to highlight the desired function and press

to open

the screen. You can also access the desired function by pressing the corresponding

function key.

AK Status

Содержание 700 NDIR

Страница 1: ...700 NDIR Analyzer 6 20 2017 1 ...

Страница 32: ...700 NDIR Analyzer 6 20 2017 32 ...

Страница 99: ...700 NDIR Analyzer 6 20 2017 99 Comp Factors or ...

Страница 100: ...700 NDIR Analyzer 6 20 2017 100 T P Compensation H2O Compensation ...

Страница 101: ...700 NDIR Analyzer 6 20 2017 101 Gas Compensation ...