81

Verifying the installation and setup

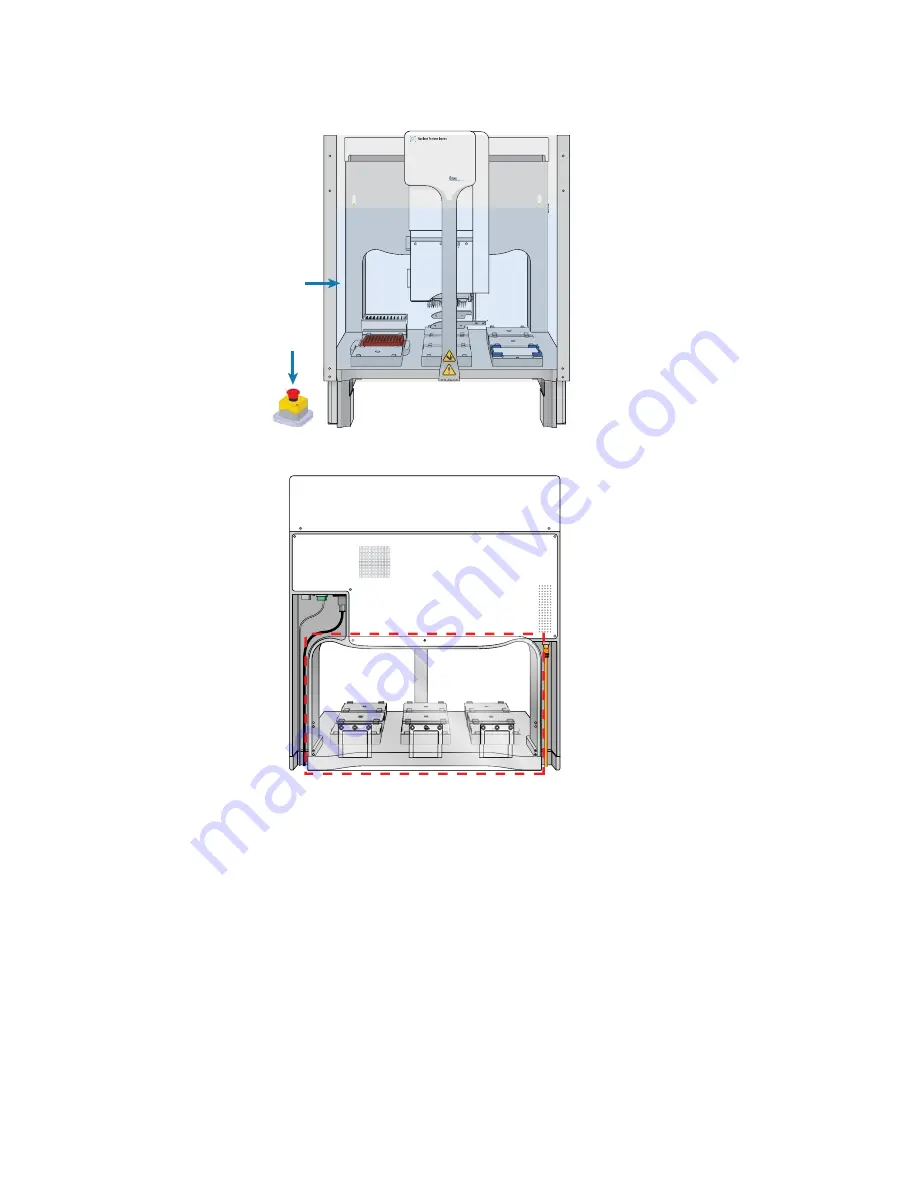

About installing the Bravo pendant, Light Curtain, and shields

AssayMAP Bravo Platform Installation Guide

Figure

AssayMAP Bravo Platform with Light Curtain and emergency-stop pendant

Figure

Bravo rear shield with access window covers installed

00220

Bravo

Back

20c

Содержание AssayMAP Bravo

Страница 1: ...AssayMAP Bravo Platform Installation Guide Original Instructions...

Страница 86: ...Setting the teachpoints Checking and adjusting the gripper offset 78 AssayMAP Bravo Platform Installation Guide...

Страница 113: ......

Страница 114: ...Agilent Technologies Installation Guide G5571 90001 Revision B March 2018...