Fault tracing

285

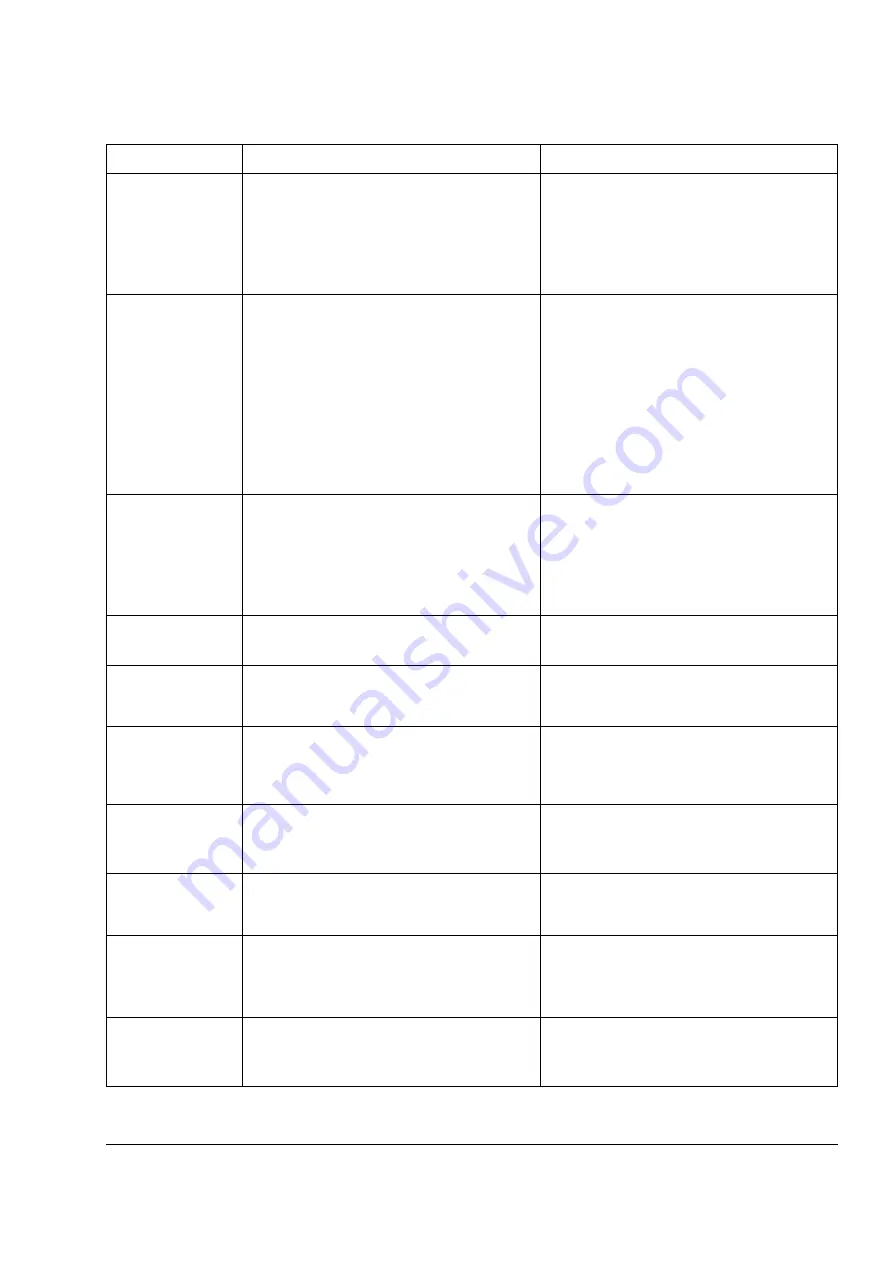

MOT POW LIM

(FF86)

3.18 AW 5 bit 12

(programmable

Fault Function

Drive limits motor power according to limits

defined with parameters

and

.

Informative alarm

Check parameter

P MOTORING LIM

and

P GENERATING LIM settings.

Check Fault Function parameters.

MOT TORQ LIM

(FF85)

3.18 AW 5 bit 11

(programmable

Fault Function

Drive limits motor torque according to

calculated motor pull-out torque limit and

minimum and maximum torque limits defined

with parameters

and

.

Informative alarm

Check parameter

MIN TORQ SEL and

MAX TORQ SEL settings.

Check Fault Function parameters.

If LIMIT WORD 1 bit 0 TORQ MOTOR LIM

is 1,

- check motor parameter settings (parameter

group

- ensure that ID run has been completed

successfully.

PANEL LOSS

(5300)

3.09 AW 2 bit 13

(programmable

Fault Function

Control panel selected as active control

location for drive has ceased communicating.

Check panel connection (see appropriate

hardware manual).

Check control panel connector.

Replace control panel in mounting platform.

Check Fault Function parameters.

POINTER ERROR

(FFD0)

Source selection (pointer) parameter points to

non existing parameter index.

Check source selection (pointer) parameter

settings.

->POWEROFF!

(FF39)

Inverter type (for example, sr0025_3) has been

changed. Inverter type is usually changed at

factory or during drive implementation.

Switch control board power off to validate

inverter type change.

PP OVERLOAD

(5482)

3.18 AW 5 bit 5

Excessive IGBT junction to case temperature.

This can be caused by excessive load at low

frequencies (for example, fast direction change

with excessive load and inertia).

Increase ramp time.

Reduce load.

REPLACE FAN

(4280)

3.18 AW 5 bit 0

Running time of inverter cooling fan has

exceeded its estimated life time.

Replace fan.

Reset fan run time counter

.

SLOW DOWN UP

(FFF4)

Slowdown signal

activated in the Up

direction

Run the motor in the opposite direction and

deactivate the Slowdown signal. Or let the

drive run in the limited speed reference.

SLOW DOWN

DOWN

(FFF5)

Slowdown signal

activated in the down

direction

Run the motor in the opposite direction and

deactivate the Slowdown signal. Or let the

drive run in the limited speed reference.

START INHIBI

(FF7A)

AW 1 bit 0

Optional start inhibit hardware logic is

activated.

Check start inhibit circuit (AGPS board).

WARNING

CAUSE

WHAT TO DO

Содержание ACS 800 Series

Страница 1: ...ACS800 Firmware Manual Crane Control Program N697 ...

Страница 4: ......

Страница 26: ...Start up and control through the I O interface 26 ...

Страница 36: ...Quick start up guide 36 ...

Страница 52: ...Control panel 52 ...

Страница 105: ...Program features 105 Figure Control diagram for Shaft synchronisation executed in 20 ms ...

Страница 126: ...Program features 126 The figures below show speed limits according to different load conditions ...

Страница 128: ...Program features 128 ...

Страница 150: ...Application macros control location EXT1 EXT2 150 ...

Страница 228: ...Actual signals and parameters 228 ...

Страница 299: ...Adaptive Programming examples for crane control 299 ...

Страница 305: ...Adaptive Programming examples for crane control 305 ...

Страница 312: ...Adaptive Programming examples for crane control 312 The following figures show the previous example enlarged ...

Страница 314: ...Adaptive Programming examples for crane control 314 The following figures show the previous example enlarged ...

Страница 318: ...Analogue Extension Module 318 ...

Страница 332: ...Additional data actual signals and parameters 332 ...

Страница 333: ...DriveWindow 333 DriveWindow DriveWindow connected to the ACS800 RMIO RDCO board and channel CH3 ...

Страница 334: ...DriveWindow 334 ...

Страница 335: ...Control block diagrams 335 Control block diagrams ...

Страница 336: ...Control block diagrams 336 ...

Страница 337: ...Control block diagrams 337 ...

Страница 338: ...Control block diagrams 338 ...

Страница 340: ...www abb com drives www abb com drivespartners Contact us 3AFE68775230 Rev E EN 2012 09 25 ...