Start-up and control through the I/O interface

24

How to perform the ID run

The drive performs the ID Magnetisation automatically at the first start. In most

applications there is no need to perform a separate ID run. The ID run (STANDARD)

should be selected if:

• The operation point is near zero speed, and/or

• Operation at torque range above the motor nominal torque within a wide speed

range and without any measured speed feedback is required.

ID run procedure

Note:

If parameter values (Group 10 … 98) are changed before the ID run, check

that the new settings meet the following conditions:

• 20.01 MINIMUM SPEED < 0 rpm

• 20.02 MAXIMUM SPEED > 80% of motor rated speed

• 20.03 MAXIMUM CURRENT > 100% ·

I

hd

• 20.04 TORQ MAX LIM1 > 50%

• Ensure that the panel is in the local control mode (L displayed on the status row).

Press the

LOC/REM

key to switch between modes.

• Change the ID run selection to STANDARD.

• Press

ENTER

to verify the selection. The following message is displayed:

• If brake control is active, the brake is opened when STANDARD ID run is

selected.

• To start the ID run, press the

key. The Run Enable signal must be active (see

parameter

RUN ENABLE).

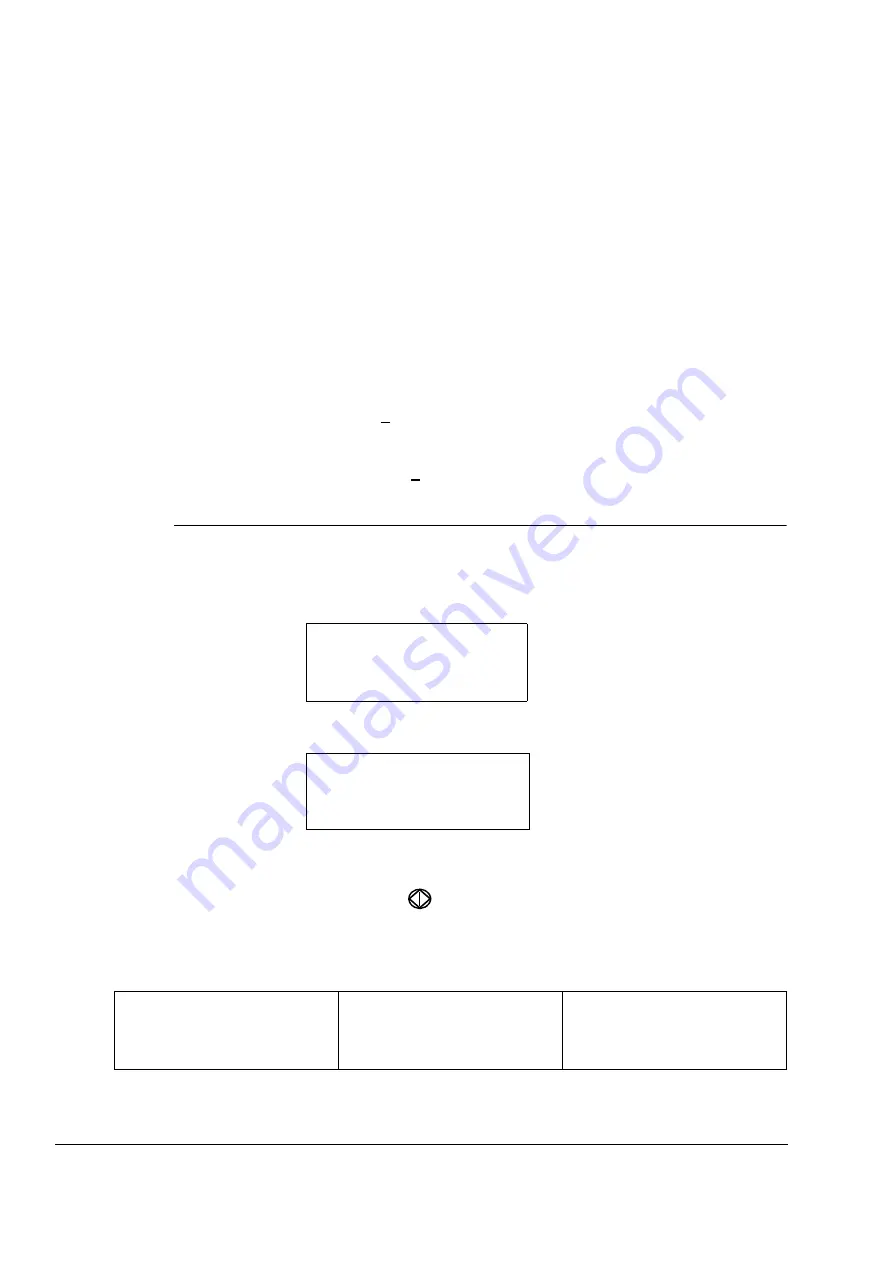

Warning when the ID run is

started

Warning during the ID run

Warning after a successfully

completed ID Run

1 L -> 1242.0 rpm I

ACS800

**WARNING**

MOTOR STARTS

1 L -> 1242.0 rpm I

ACS800

**WARNING**

ID RUN

1 L -> 1242.0 rpm I

ACS800

**WARNING**

ID DONE

99 START-UP DATA

10 MOTOR ID RUN

[STANDARD]

1 L ->1242.0 rpm O

1 L ->1242.0 rpm O

ACS800

**WARNING**

ID RUN SEL

Содержание ACS 800 Series

Страница 1: ...ACS800 Firmware Manual Crane Control Program N697 ...

Страница 4: ......

Страница 26: ...Start up and control through the I O interface 26 ...

Страница 36: ...Quick start up guide 36 ...

Страница 52: ...Control panel 52 ...

Страница 105: ...Program features 105 Figure Control diagram for Shaft synchronisation executed in 20 ms ...

Страница 126: ...Program features 126 The figures below show speed limits according to different load conditions ...

Страница 128: ...Program features 128 ...

Страница 150: ...Application macros control location EXT1 EXT2 150 ...

Страница 228: ...Actual signals and parameters 228 ...

Страница 299: ...Adaptive Programming examples for crane control 299 ...

Страница 305: ...Adaptive Programming examples for crane control 305 ...

Страница 312: ...Adaptive Programming examples for crane control 312 The following figures show the previous example enlarged ...

Страница 314: ...Adaptive Programming examples for crane control 314 The following figures show the previous example enlarged ...

Страница 318: ...Analogue Extension Module 318 ...

Страница 332: ...Additional data actual signals and parameters 332 ...

Страница 333: ...DriveWindow 333 DriveWindow DriveWindow connected to the ACS800 RMIO RDCO board and channel CH3 ...

Страница 334: ...DriveWindow 334 ...

Страница 335: ...Control block diagrams 335 Control block diagrams ...

Страница 336: ...Control block diagrams 336 ...

Страница 337: ...Control block diagrams 337 ...

Страница 338: ...Control block diagrams 338 ...

Страница 340: ...www abb com drives www abb com drivespartners Contact us 3AFE68775230 Rev E EN 2012 09 25 ...