76

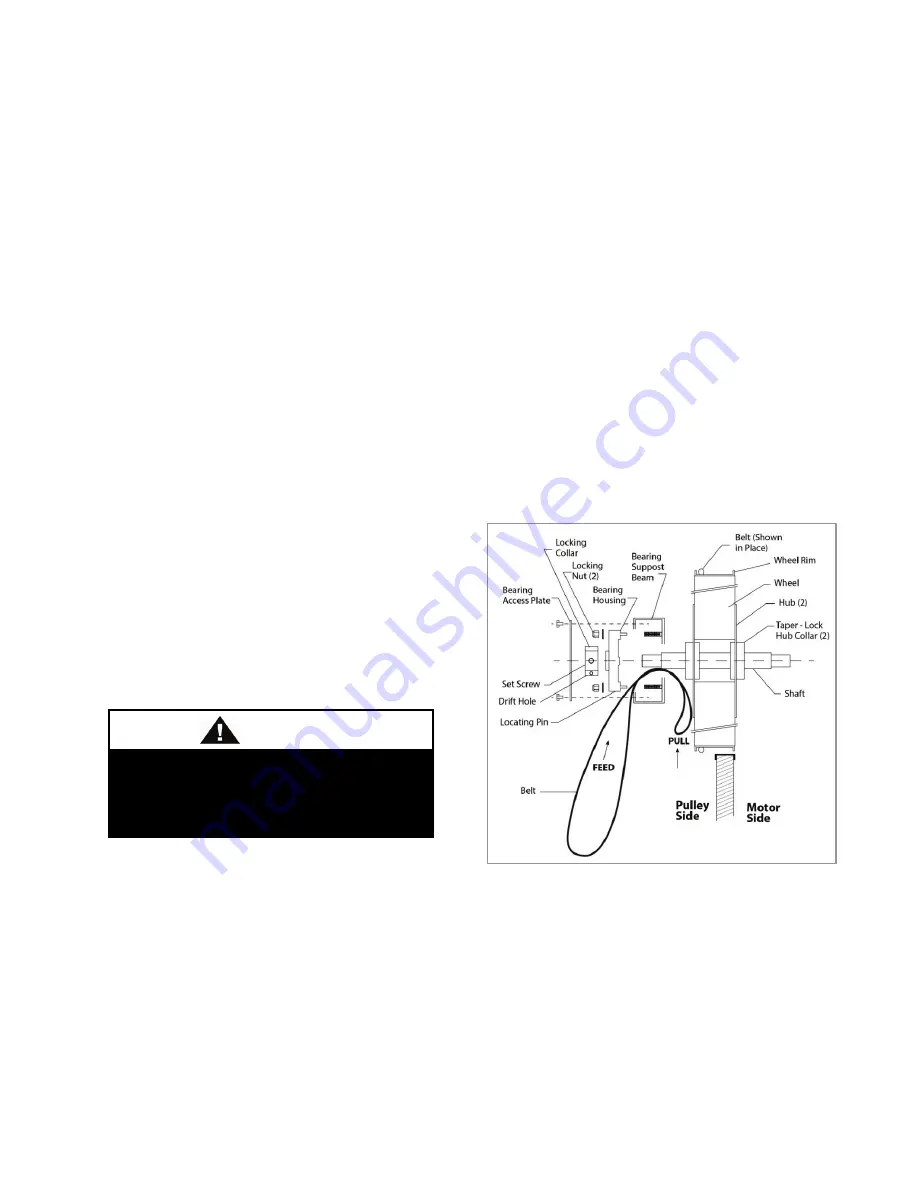

Belt Replacement

1.

Obtain access to the pulley side

bearing access plate if bearing access

plates are provided. Remove two

bearing access plate retaining screws

and the access plate.

2.

Using hexagonal wrench, loosen set

screw in bearing locking collar. Using

light hammer and drift (in drift pin

hole) tap collar in the direction of

wheel rotation to unlock collar.

Remove collar.

3.

Using socket wrench with extension,

remove two nuts which secure

bearing housing to the bearing

support beam. Slide bearing from

shaft. If not removable by hand, use

bearing puller.

4.

Form a small loop of belt and pass it

through the hole in the bearing

support beam. Grasp the belt at the

wheel hub and pull the entire belt

down.

Note:

Slight hand pressure against wheel rim

will lift weight of wheel from inner race of

bearing to assist bearing removal and

installation.

5.

Loop the trailing end of the belt over

the shaft (belt is partially through the

opening).

6.

Reinstall the bearing onto the wheel

shaft, being careful to engage the two

locating pins into the holes in the

bearing support beam. Secure the

bearing with two self-locking nuts.

7.

Install the belts around the wheel and

pulley according to the instructions

provided with the belt.

8.

Reinstall diameter seals or hub seal

and tighten retaining screws. Rotate

wheel in clockwise direction to

determine that wheel rotates freely

with slight drag on seals.

9.

Reinstall bearing locking collar.

Rotate collar by hand in the direction

the wheel rotates (see label provided

on each cassette for wheel rotation).

10.

Lock in position by tapping drift pin

hole with hammer and drift. Secure in

position by tightening set screw.

11.

Reinstall Bearing Access Cover.

12.

Apply power to wheel and ensure that

the wheel rotates freely without

interference.

Belt Replacement

Protect hands and belt from possible

sharp edges of hole in Bearing

Support Beam.

CAUTION

Содержание RQ NextGen Series

Страница 2: ......

Страница 26: ...26 Figure 3 RQ Cabinet Standard and Power Exhaust Gasket Locations...

Страница 40: ...40 Figure 23 Post Corner Hole Piping Figure 24 Post Back Hole Piping...

Страница 86: ...86 Figure 35 Example 2 6 ton through the Base Gas Piping Note RQ units will only contain one Heat Exchanger...

Страница 88: ...88 Gas Heater Operating Instructions Figure 36 Gas Heater Instructions...

Страница 95: ...95...

Страница 96: ...96...

Страница 105: ...105 Maintenance Log E Coated Coil...

Страница 107: ...107...