60

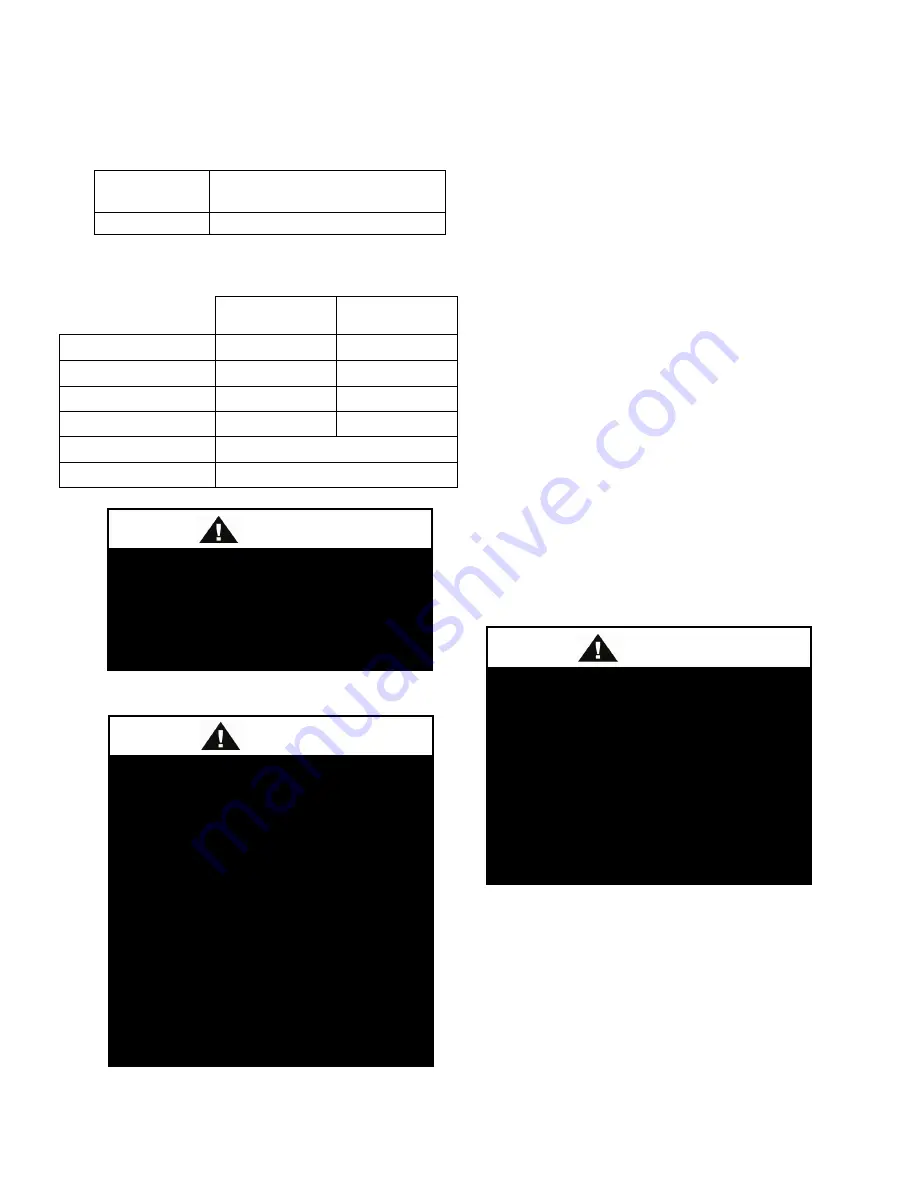

Table 20 - Chilled Water Coil Connection

Sizes

Model (RQ-)

Chilled Water Coil

Connection Size [mm (in.)]

002-006

29 (1 1/8)

Table 21 – Min and Max Water Pressures

and Temps

Packaged Direct Expansion (DX) Units

DX refrigeration system is factory

assembled, leak tested, charged with

refrigerant and run tested.

Refrigerant system includes an evaporator,

condenser, liquid line filter drier, thermal

expansion valve (TXV), and scroll

compressor. Variable speed compressor

systems include an electronic expansion

valve (EEV). Compressor is equipped with a

positive pressure forced lubrication system.

Never cut off the main power supply to the

unit, except for servicing, emergency, or

complete shutdown of the unit. When power

is cut off from the unit crankcase heater

cannot prevent refrigerant migration into the

compressor. This means the compressor will

cool down and liquid refrigerant may

accumulate in the compressor. The

compressor is designed to pump refrigerant

gas and damage may occur when power is

restored.

If power to the unit must be off for more than

an hour, turn the thermostat system switch to

"OFF", or turn the unit off at the control

panel, and leave the unit off until the main

power switch has been turned on again for at

least 24 hours for units with compressor

crankcase heaters. This will give the

crankcase heater time to clear any liquid

Chilled Water

Hot Water

Min. Entering Air

15.6°C (60

°

F)

4.4 °C (40

°

F)

Max Entering Air

37.8°C (100

°

F) 26.7°C (80

°

F)

Min. Entering Water

1.7°C (35°F)

60°C (140°F)

Max Entering Water 18.3°C (65

°

F) 93.3°C (200

°

F)

Min. Water Pressure

0 kpa (15 psig)

Max Water Pressure

2068kpa (300 psig)

The unit shall have proper sealing of

the water piping entries into the unit.

Failure to seal the entries may result

in damage to the unit and property.

CAUTION

COMPRESSOR CYCLING

3 MINUTE MINIMUM OFF TIME

To prevent motor overheating

compressors must cycle off for a

minimum of 3 minutes.

5 MINUTE MINIMUM ON TIME

To maintain the proper oil level

compressors must cycle on for a

minimum of 5 minutes.

The cycle rate must not exceed 7

starts per hour.

WARNING

CRANKCASE HEATER

OPERATION

Some units are equipped with a

compressor crankcase heater, which

must be energized at least 24 hours

prior to cooling operation, to clear any

liquid refrigerant from the compressor.

CAUTION

Содержание RQ NextGen Series

Страница 2: ......

Страница 26: ...26 Figure 3 RQ Cabinet Standard and Power Exhaust Gasket Locations...

Страница 40: ...40 Figure 23 Post Corner Hole Piping Figure 24 Post Back Hole Piping...

Страница 86: ...86 Figure 35 Example 2 6 ton through the Base Gas Piping Note RQ units will only contain one Heat Exchanger...

Страница 88: ...88 Gas Heater Operating Instructions Figure 36 Gas Heater Instructions...

Страница 95: ...95...

Страница 96: ...96...

Страница 105: ...105 Maintenance Log E Coated Coil...

Страница 107: ...107...