44

Subtract the measured liquid line temperature

from the saturated temperature to determine

the liquid sub-cooling.

Compare calculated sub-cooling to Table 7

and Table 8 for the appropriate unit type and

options.

Checking Evaporator Superheat

Measure the temperature of the suction line

close to the compressor. Read gauge pressure

at the suction line close to the compressor.

Convert the pressure obtained to a saturated

temperature using the appropriate refrigerant

temperature-pressure chart.

Subtract the saturated temperature from the

measured suction line temperature to

determine the evaporator superheat.

Compare calculated superheat to the table

below for the appropriate unit type and

options.

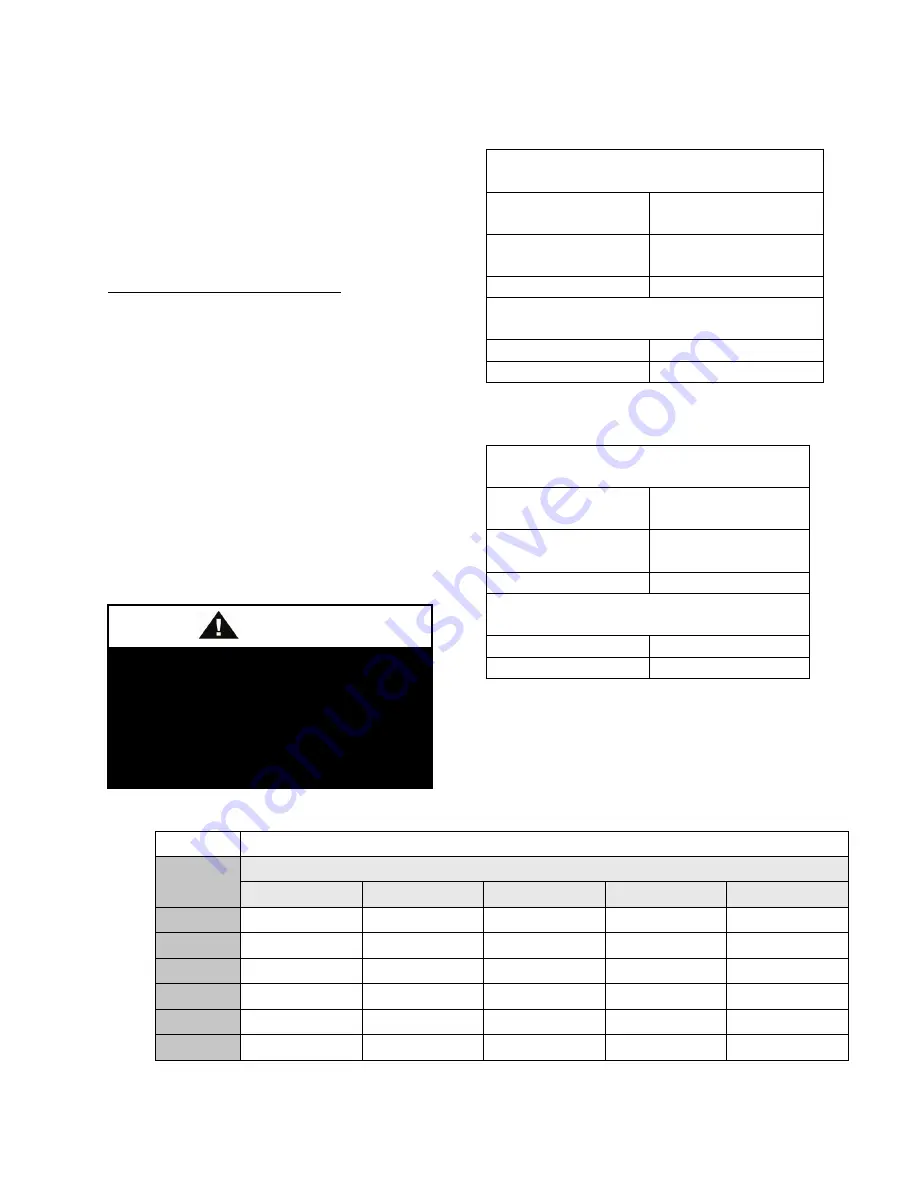

Table 9 - Acceptable Refrigeration Circuit

Values (Metric)

Air-Cooled Cond./Air-Source Heat Pump

In Cooling Mode

Sub-Cooling

4.4-8.3°C / 1.1-2.2°C

(HP)*

Sub-Cooling with

Hot Gas Reheat

4.4-8.3°C /1.1-3.3°C

(HP)*

Superheat

4.4-8.3°C

Water-Cooled Cond./Water-Source Heat

Pump In Cooling Mode

Sub-Cooling

2.2-4.4°C

Superheat

4.4-8.3°C

Table 10 – Acceptable Refrigeration Circuit

Values (Imperial)

Air-Cooled Cond./Air-Source Heat

Pump In Cooling Mode

Sub-Cooling

8-15°F / 2-4°F

(HP)*

Sub-Cooling with

Hot Gas Reheat

8-15°F /2-6°F

(HP)*

Superheat

8-15°F

Water-Cooled Cond./Water-Source

Heat Pump In Cooling Mode

Sub-Cooling

4-8°F

Superheat

8-15°F

Table 11 - Acceptable Microchannel Air-Cooled Condenser Coil Liquid Sub-

Cooling Values (Metric)

Cooling Mode Liquid Sub-Cooling Values(°C)

Ambient

(°C)

Evaporator Coil Saturation Temperature (°C)

4.4

7.2

8.9

10.0

12.8

19.4

5.0 - 7.8

4.4 - 7.2

4.4 - 7.2

3.9 - 6.7

2.8 - 5.6

22.2

5.6 - 8.3

5.0 - 7.8

5.0 - 7.8

4.4 - 7.2

3.9 - 6.7

27.8

5.6 - 8.3

5.6 - 8.3

5.6 - 8.3

5.0 - 7.8

3.9 - 6.7

35.0

5.6 - 8.3

5.6 - 8.3

5.6 - 8.3

5.0 - 7.8

4.4 - 7.2

40.6

6.1 - 8.9

6.1 - 8.9

5.6 - 8.3

5.6 - 8.3

4.4 - 7.2

46.1

5.6 - 8.3

6.1 - 8.9

6.1 - 8.9

6.1 - 8.9

5.0 - 7.8

Thermal expansion valve must be

adjusted to approximately 4.4-8.3°C

(8-15°F) of suction superheat. Failure

to have sufficient superheat will

damage the compressor and void the

warranty.

CAUTION

Содержание RQ NextGen Series

Страница 2: ......

Страница 26: ...26 Figure 3 RQ Cabinet Standard and Power Exhaust Gasket Locations...

Страница 40: ...40 Figure 23 Post Corner Hole Piping Figure 24 Post Back Hole Piping...

Страница 86: ...86 Figure 35 Example 2 6 ton through the Base Gas Piping Note RQ units will only contain one Heat Exchanger...

Страница 88: ...88 Gas Heater Operating Instructions Figure 36 Gas Heater Instructions...

Страница 95: ...95...

Страница 96: ...96...

Страница 105: ...105 Maintenance Log E Coated Coil...

Страница 107: ...107...