The value is set as a percentage of the maximum frequency. If L6-08 is set for unsigned speed detection (L6-08 = 2, 4, 6, 8)

then the absolute value of L6-09 is used, i.e., negative settings will be treated as positive.

n

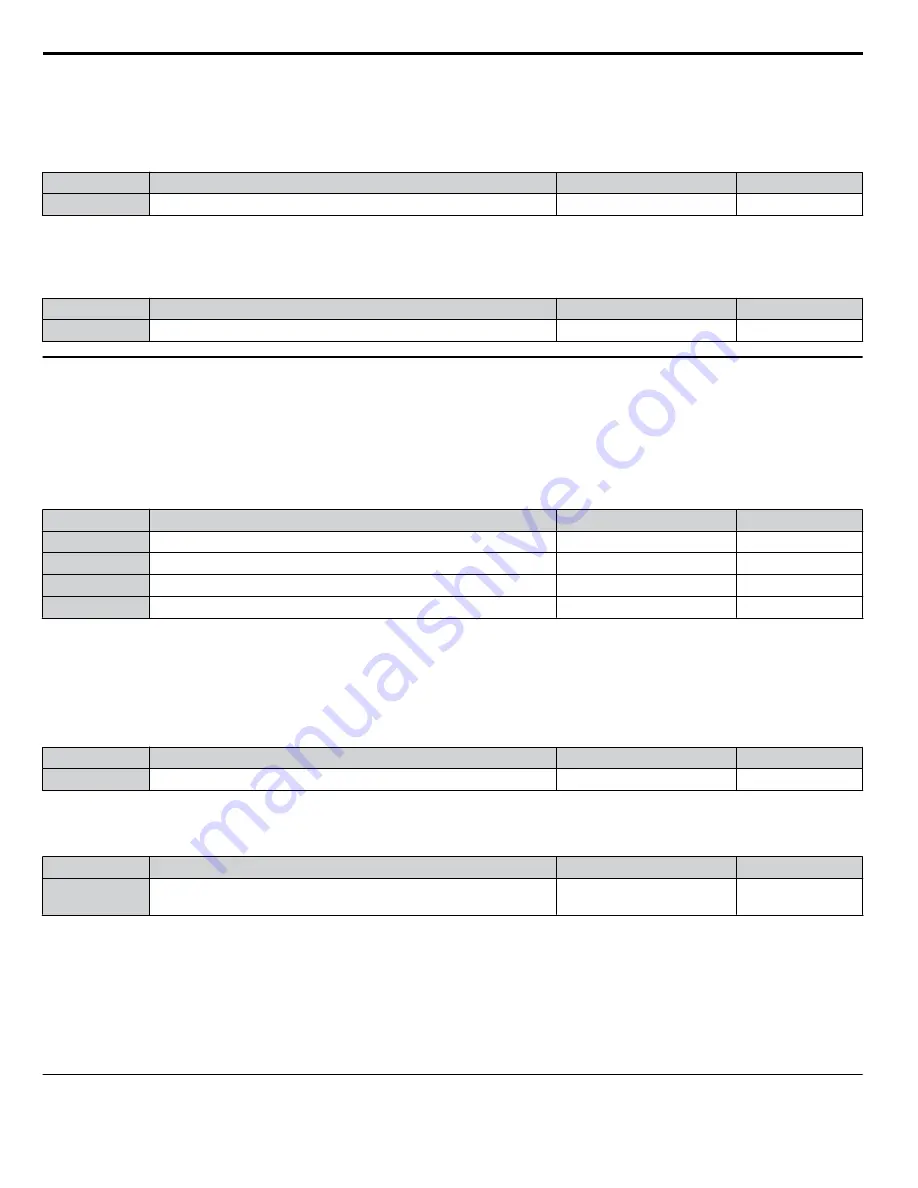

L6-10: Mechanical Weakening Detection Time

Sets the time permitted for the situation selected in parameter L6-08 to arise before mechanical weakening is detected.

No.

Name

Setting Range

Default

L6-10

Mechanical Weakening Detection Time

0.0 to 10.0 s

0.1 s

n

L6-11: Mechanical Weakening Detection Start Time

Sets the drives cumulative operation time at which mechanical weakening detection is activated. If U4-01 reaches the L6-11

value, the function is activated.

No.

Name

Setting Range

Default

L6-11

Mechanical Weakening Detection Start Time

0 to 65535 h

0 h

u

L7: Torque Limit

The torque limit function can be used to limit the torque in each of the four quadrants individually and thereby protect the

machinery. It can be used in the Open Loop Vector Control mode. A digital output programmed for “During Torque Limit”

(H2-01/02/03 = 30) can be switched when the drive is operating at the torque limit.

n

L7-01/02/03/04: Torque Limits

These parameters set the torque limits in each operation mode.

No.

Name

Setting Range

Default

L7-01

Forward Torque Limit

0 to 300%

200%

L7-02

Reverse Torque Limit

0 to 300%

200%

L7-03

Forward Regenerative Torque Limit

0 to 300%

200%

L7-04

Reverse Regenerative Torque Limit

0 to 300%

200%

Note:

If the multi-function analog input is programmed for “10: Positive Torque Limit”, “11: Negative Torque Limit”, “12: Regenerative Torque

Limit”, or “15: General Torque Limit”, the drive uses the lower value of either L7-01 through L7-04, or analog input torque limit.

to Setting 10/11/12/15: Positive/Negative/Regenerative/General Torque Limit (OLV only) on page 209

for details on using analog torque

limits.

n

L7-06: Torque Limit Integral Time Constant

Sets the integral time constant for the torque limit function.

No.

Name

Setting Range

Default

L7-06

Torque Limit Integral Time Constant

5 to 10000 ms

200 ms

n

L7-07: Torque Limit Control Method Selection during Accel/Decel

Selects the function of torque limit during acceleration and deceleration.

No.

Name

Setting Range

Default

L7-07

Torque Limit Control Method Selection during Acceleration/

Deceleration

0 or 1

0

Setting 0: Proportional Control

The torque limit function works with P-control during acceleration and deceleration and switches to I-control at constant speed.

Use this setting when acceleration or deceleration to the desired speed has priority over torque limitation during speed changes.

Setting 1: Integral Control

The torque limit function always uses I-control. Use this setting when high accuracy torque limitation is required even during

speed changes. Using this function may increase the acceleration time, or may prevent the motor speed from reaching the

frequency reference when the torque limit is reached before.

u

L8: Hardware Protection

5.8 L: Protection Functions

234

YASKAWA ELECTRIC SIEP C710606 18F YASKAWA AC Drive – V1000 Technical Manual