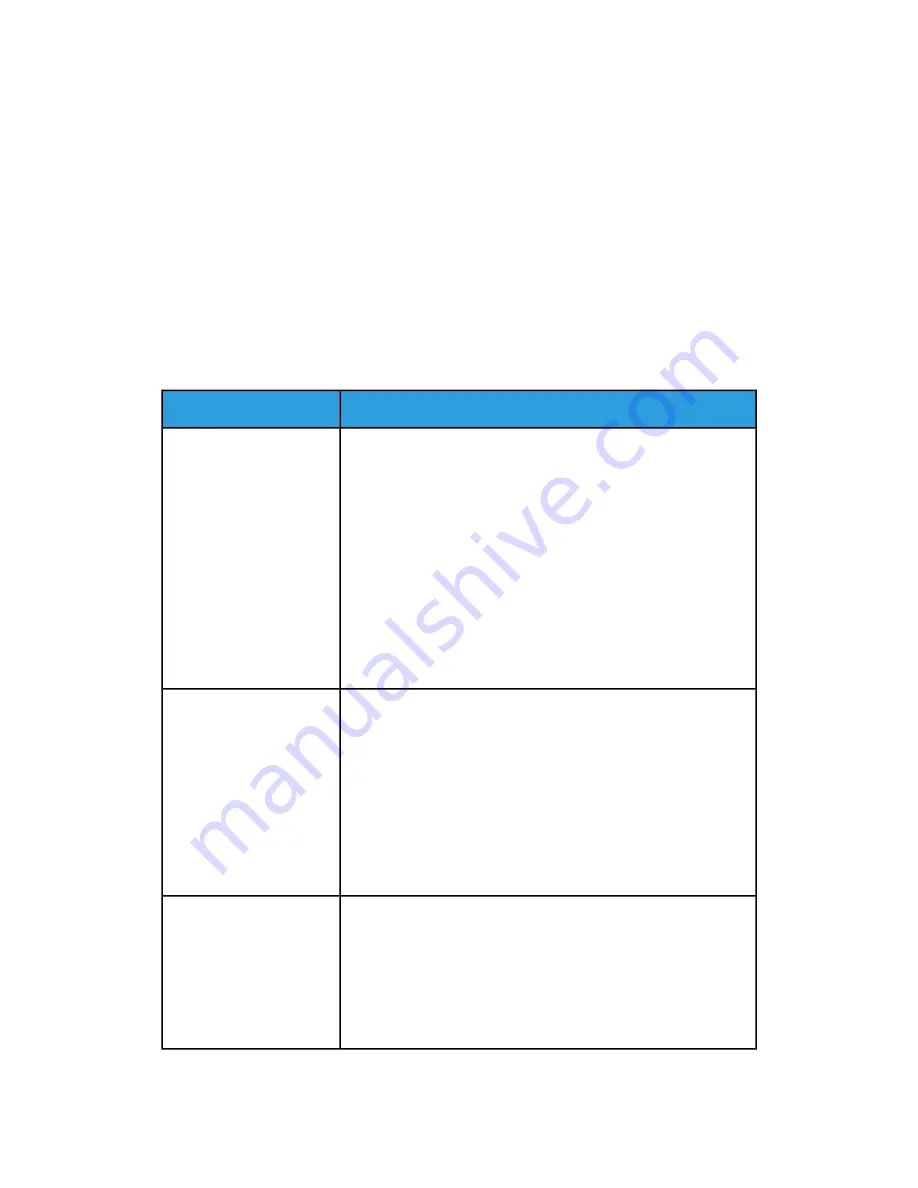

Image Quality Problems

The following table helps you locate and resolve an image quality defects on the press.

Initial Actions

Perform these actions first to improve image quality:

• Manage the stock in use. Ensure that the media used is approved, within press

specifications and is clean.

• Ensure the correct media is properly loaded in the paper tray.

• Run print samples and evaluate the defect. From the following table, determine which

problem description matches the IQ defect and perform the appropriate corrective

actions.

Suggested Solutions

Problem

Print Backside Contamina-

tion

The back side of the output

a 10-15 mm wide toner

streak running from lead

edge (LE) / trail edge (TE),

near the outboard side (OB)

side of print.

• Contamination can be media related. Look for paper damage,

paper dust, or environmental conditions that may contribute.

Ensure media is fresh and properly loaded in the Trays.

• Defects occur on Heavyweight stock with light weight stock

settings. Ensure the proper Custom Paper Settings are con-

figured for the media in use. For information and procedures,

refer to the System Administrators Guide, Paper Tray Settings

(System Settings chapter / Common Service Settings section).

• If the defect is the specific backside streak, there may be a

second bias transfer roll (2

nd

BTR) failure. Run the

routine. If the problem continues, contact the

Customer Support Center.

Acquire the measuring tool from the Nationalization Kit. Check

the frequency of the defect interval.

Banding

The print shows lines or

bands running from In-

board to Outboard (IB/OB).

For defects running Lead

Edge to Trail Edge (LE/TE),

see Streaks and Lines.

• If the defect is at interval 37.5 mm or 147 mm, troubleshoot

a failed drum cartridge; refer to

• If the defect is defect at interval 154 mm, the problem may be

with the Pressure Roll Assembly (fuser assembly; contact the

Customer Support Center.

• If the defect is 375 mm, the problem may be Fuser Belt failures;

contact the Customer Support Center.

Color Non-Uniformity

The print has variations in

color uniformity, unneven

density, light or dark areas

from side to side (IB/OB), or

color shift or inconsistent

color within the page.

• Perform the

procedure.

• Perform the Density Uniformity Adjustment procedure; for

specific instructions, refer to the System Administration Guide,

Simple Image Quality (SIQA) chapter.

• Refer to the Custom Paper Settings Troubleshooting table, and

review the Suggested Solutions for

Xerox

®

Versant

®

180 Press

6-8

User Guide

Troubleshooting

Summary of Contents for Versant 180 Press

Page 1: ...Xerox Versant 180 Press User Guide Book Version 1 0 February 2017 702P04572 ...

Page 9: ...Environmental Specifications 7 5 vii Xerox Versant 180 Press User Guide Table of Contents ...

Page 10: ...Xerox Versant 180 Press viii User Guide Table of Contents ...

Page 16: ...Xerox Versant 180 Press 1 6 User Guide Product Symbols ...

Page 26: ...Xerox Versant 180 Press 2 10 User Guide Getting Started ...

Page 96: ...Xerox Versant 180 Press 3 70 User Guide Press Apps ...

Page 108: ...Xerox Versant 180 Press 4 12 User Guide Paper and Media ...

Page 122: ...Xerox Versant 180 Press 5 14 User Guide Maintenance ...

Page 164: ...Xerox Versant 180 Press 7 6 User Guide Specifications ...

Page 165: ......

Page 166: ......