Greensmaster 3320/3420

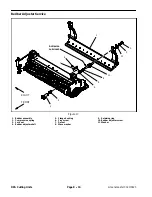

DPA Cutting Units

Page 8 -- 22

6. Install shoulder bolts (item 4) and flange nuts (item

5) to secure the LH side plates to the crossmember.

Torque the shoulder bolts from

210 to 240 in--lb (24 to

27 N--m)

.

7. Position crosslink to pitch arms and secure with

washer head screws (item 3).

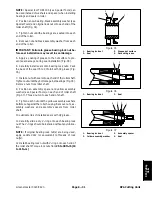

8. If bearing lock nut (RH threads) and reel nut (LH

threads) were loosened during cutting reel service, put

a block of wood between the cutting reel blades to pre-

vent the reel from rotating. Torque bearing lock nut (RH

threads) and reel nut (LH threads) from

90 to 110 ft--lb

(123 to 149 N--m)

(Fig. 23).

9. Thoroughly fill spline area of reel nut (left side of cut-

ting reel) with grease.

10.Secure the bedbar assembly to LH side plate (see

Bedbar Installation in this section). Make sure that plas-

tic and steel washers are properly positioned.

11. Secure front and rear rollers to LH side plate (see

Front Roller Installation and Rear Roller Installation in

this section).

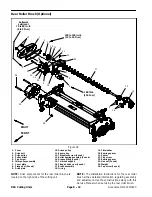

12.Adjust cutting unit (see Cutting Unit Operator’s

Manual).

NOTE:

The parallel position of the rear roller to the cut-

ting reel is controlled by the precision machined cross-

member and side plates of the cutting unit. If necessary,

the cutting unit side plates can be loosened and a slight

adjustment can be made to parallel the rear roller with

the cutting reel (see Leveling Rear Roller in the Set--Up

and Adjustments section of this Chapter).

13.Install new O--ring (item 12) on weight. Secure

weight assembly (items 10 and 20) to RH side plate with

two (2) cap screws and nuts.

14.If cutting unit is equipped with optional groomer or

rear roller brush, install components for those options to

cutting unit. See Service and Repairs section of Chapter

8 -- Groomer for information on groomer. See Rear Roll-

er Brush in this section for information on rear roller

brush.

15.Install cutting unit to the machine.

Summary of Contents for Greensmaster 3420 TriFlex

Page 2: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 4: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 6: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 24: ...Greensmaster 3320 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3420 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3420 Page 4 20 Diesel Engine This page is intentionally blank ...

Page 56: ...Greensmaster 3320 3420 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 150: ...Greensmaster 3320 3420 Hydraulic System Page 5 96 This page is intentionally blank ...

Page 250: ...Greensmaster 3320 3420 Page 6 100 Electrical System This page is intentionally blank ...

Page 277: ...Greensmaster 3320 3420 Page 7 27 Chassis This page is intentionally blank Chassis ...

Page 325: ...Greensmaster 3320 3420 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 340: ...Greensmaster 3320 3420 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 347: ...Page 10 9 This page is intentionally blank ...

Page 356: ...Page 10 18 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Below 312000000 ...

Page 358: ...Page 10 20 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Above 312000000 ...

Page 360: ...Page 10 22 This page is intentionally blank ...