Greensmaster 3320/3420

Page 6 -- 69

Electrical System

Temperature Sender (Greensmaster 3420)

The temperature sender is located near the alternator

on the water flange attached to the engine cylinder head

(Fig. 88).

The resistance of the temperature sender reduces as

the engine coolant temperature increases. The chang-

ing resistance of the temperature sender signals the

console temperature gauge to indicate engine coolant

temperature during machine operation.

Temperature Sender Test

1. Park machine on a level surface, lower cutting units,

stop engine, apply parking brake and remove key from

ignition switch.

2. Locate temperature sender on engine and discon-

nect wire harness connector from sender.

CAUTION

Make sure engine is cool before removing the

temperature sender from engine.

3. Lower coolant level in the engine and remove the

temperature sender from water flange.

4. Put sender in a container of oil with a thermometer

and slowly heat the oil (Fig. 89).

CAUTION

Handle the hot oil with extreme care to prevent

personal injury or fire.

NOTE:

Prior to taking resistance readings with a digital

multi meter, short the meter test leads together. The me-

ter will display a small resistance value (usually 0.5

ohms or less) due to the internal resistance of the meter

and test leads. Subtract this value from from the mea-

sured value of the component you are testing.

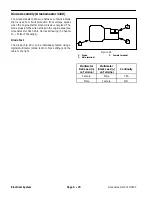

5. Check resistance of the sender with a multimeter

(ohms setting) as the oil temperature increases.

A. The meter should indicate from 11.4 to 13.6 ohms

at 68

o

F (20

o

C).

B. The meter should indicate from 2.3 to 2.6 ohms at

140

o

F (60

o

C).

C. The meter should indicate from 0.6 to 0.7 ohms at

212

o

F (100

o

C).

6. Replace temperature sender if specifications are not

met.

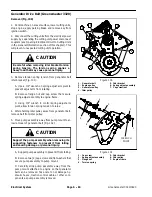

7. Install temperature sender to the water flange.

A. Clean threads of water flange and temperature

sender thoroughly. Apply thread sealant to the

threads of the sender.

B. Screw sender into the water flange until it is finger

tight. Then, tighten sender an additional 2 to 3 full

turns.

C. Connect wire harness connector to sender.

8. Fill engine cooling system.

Figure 88

1. Temperature sender

2. Alternator

2

1

Figure 89

Elec

trica

l

System

Summary of Contents for Greensmaster 3420 TriFlex

Page 2: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 4: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 6: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 24: ...Greensmaster 3320 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3420 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3420 Page 4 20 Diesel Engine This page is intentionally blank ...

Page 56: ...Greensmaster 3320 3420 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 150: ...Greensmaster 3320 3420 Hydraulic System Page 5 96 This page is intentionally blank ...

Page 250: ...Greensmaster 3320 3420 Page 6 100 Electrical System This page is intentionally blank ...

Page 277: ...Greensmaster 3320 3420 Page 7 27 Chassis This page is intentionally blank Chassis ...

Page 325: ...Greensmaster 3320 3420 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 340: ...Greensmaster 3320 3420 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 347: ...Page 10 9 This page is intentionally blank ...

Page 356: ...Page 10 18 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Below 312000000 ...

Page 358: ...Page 10 20 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Above 312000000 ...

Page 360: ...Page 10 22 This page is intentionally blank ...