Greensmaster 3320/3420

Page 6 -- 82

Electrical System

Battery Pack Service

Clean the battery pack with clean water and a towel. Do

not use solvents or chemicals to clean the battery pack.

When testing batteries in your Greensmaster, it is impor-

tant to test all four (4) individual batteries. Proper perfor-

mance of the machine depends on all batteries being in

good condition. Testing will determine if one (or more) of

the batteries needs to be replaced.

A simple battery test can be done using a multimeter to

perform a voltage test of each of the batteries in the bat-

tery pack. Measure the battery voltage with the multime-

ter and record battery voltage. The measured voltage

can be used to determine battery state of charge. If the

voltage of any of the batteries varies by more than 10%,

it indicates a problem with the lower voltage battery.

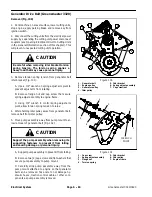

If the battery pack system voltage drops below 50VDC

due to storage, age or malfunction, battery inspection

and/or charging may be necessary. The batteries may

be individually charged with a 12V charger rated for op-

eration with absorbed glass mat (AGM), valve regulated

lead acid batteries. The voltage of this battery type is

slightly lower than flooded lead acid batteries. Maximum

charge current should be limited to 2.4 amps.

A battery load tester can be used to test individual bat-

teries. Many locally available battery load testers do not,

however, have any adjustment on the load that is put on

the battery. Results received from using load testers

should follow the recommendations of the load tester

manufacturer.

Battery Pack Storage

There are no special procedures or precautions for bat-

tery storage less than six (6) months. However, storage

above 70

o

F (21

o

C) will significantly reduce battery life.

Cold temperatures are not an issue during storage and

actually will reduce the battery self--discharge rate. To

obtain maximum battery life, do not store the battery

pack in a discharged state.

If storage is anticipated for longer than six (6) months,

inspection and/or charging is recommended at six (6)

month intervals. Battery charging is recommended

whenever the battery pack voltage drops below 50VDC

or if voltage of an individual battery drops below

12.5VDC.

Summary of Contents for Greensmaster 3420 TriFlex

Page 2: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 4: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 6: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 24: ...Greensmaster 3320 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3420 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3420 Page 4 20 Diesel Engine This page is intentionally blank ...

Page 56: ...Greensmaster 3320 3420 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 150: ...Greensmaster 3320 3420 Hydraulic System Page 5 96 This page is intentionally blank ...

Page 250: ...Greensmaster 3320 3420 Page 6 100 Electrical System This page is intentionally blank ...

Page 277: ...Greensmaster 3320 3420 Page 7 27 Chassis This page is intentionally blank Chassis ...

Page 325: ...Greensmaster 3320 3420 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 340: ...Greensmaster 3320 3420 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 347: ...Page 10 9 This page is intentionally blank ...

Page 356: ...Page 10 18 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Below 312000000 ...

Page 358: ...Page 10 20 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Above 312000000 ...

Page 360: ...Page 10 22 This page is intentionally blank ...