Greensmaster 3320/3420

Page 7 -- 23

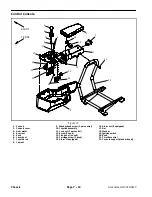

Chassis

2. Disconnect the cutting units from the electrical power

supply by separating the cutting unit power disconnect

couplers (see Opening Electrical Circuit to Cutting Units

in the General Information section of this chapter). This

will prevent unexpected cutting unit operation.

3. Remove grass basket and cutting unit from suspen-

sion assembly (see Traction Unit Operator’s Manual).

4. If front suspension assembly is to be removed, re-

move front wheel (see Wheel Removal in this section).

This will allow easier access to flange head screws that

secure suspension assembly to frame.

5. Loosen bulkhead nut that secures reel motor electri-

cal cable to bracket on suspension assembly. Separate

cable from bracket.

6. Position and support reel motor with attached electri-

cal cable away from suspension assembly.

CAUTION

Support suspension assembly when removing it

to prevent it from falling and causing personal in-

jury. Suspension assembly weighs approximate-

ly 65 pounds (30 kg).

7. Support suspension assembly to prevent it from

shifting or falling.

8. Remove three (3) flange head screws (item 2) that

secure suspension assembly to machine frame. Re-

move suspension assembly from machine.

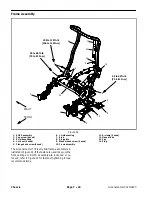

Installation (Fig. 19)

1. Make sure that all suspension components are cor-

rectly assembled.

2. Position suspension assembly to frame. Align

mounting holes and secure suspension with three (3)

flange head screws (item 2). Torques screws from

55 to

60 ft--lb (75 to 81 N--m)

.

3. Install front wheel if it was removed from machine

(see Wheel Installation in this section).

4. Position reel motor with attached electrical cable to

suspension assembly. Insert reel motor shaft into stor-

age location on front of suspension assembly.

5. Install cutting unit to suspension assembly and se-

cure reel motor to cutting unit. (see Traction Unit Opera-

tor’s Manual).

6. Position electrical cable fitting into bracket on sus-

pension assembly. Secure cable with bulkhead nut.

7. Install grass basket to suspension assembly.

8. Connect the cutting unit power disconnect couplers.

Chas

sis

Summary of Contents for Greensmaster 3420 TriFlex

Page 2: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 4: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 6: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 24: ...Greensmaster 3320 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3420 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3420 Page 4 20 Diesel Engine This page is intentionally blank ...

Page 56: ...Greensmaster 3320 3420 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 150: ...Greensmaster 3320 3420 Hydraulic System Page 5 96 This page is intentionally blank ...

Page 250: ...Greensmaster 3320 3420 Page 6 100 Electrical System This page is intentionally blank ...

Page 277: ...Greensmaster 3320 3420 Page 7 27 Chassis This page is intentionally blank Chassis ...

Page 325: ...Greensmaster 3320 3420 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 340: ...Greensmaster 3320 3420 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 347: ...Page 10 9 This page is intentionally blank ...

Page 356: ...Page 10 18 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Below 312000000 ...

Page 358: ...Page 10 20 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Above 312000000 ...

Page 360: ...Page 10 22 This page is intentionally blank ...