Greensmaster 3320/3420

Page 6 -- 39

Electrical System

Neutral and Mow Switches

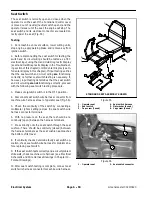

The neutral and mow switches are normally open prox-

imity switches that mount to the console assembly (Fig.

32). The sensing plate for these switches is a tab on the

functional control lever. The Toro Electronic Controller

(TEC) monitors the operation of the neutral and mow

switches.

When the functional control lever is in the neutral posi-

tion, the tab on the lever is positioned near the target end

of the neutral switch causing the switch to close. The tab

on the functional control lever is moved away from the

neutral switch when the lever is in either the mow or

transport position causing the switch to be in its normal

open state.

When the functional control lever is in the mow position,

the tab on the lever is positioned near the target end of

the mow switch causing the switch to close. The tab on

the functional control lever is moved away from the mow

switch when the lever is in either the neutral or transport

position causing the switch to be in its normal open

state.

Adjustment

1. Remove console cover from console assembly to

gain access to switches (see Control Console Disas-

sembly in the Service and Repairs section of Chapter 7

-- Chassis).

2. When the functional control lever is placed in the

neutral or mow position, the gap between the appropri-

ate switch head and the tab on the functional lever

should be from

0.090” to 0.120” (2.3 to 3.0 mm)

(Fig.

33).

3. If gap is incorrect, loosen jam nuts that secure switch

to console bracket. Position switch with jam nuts to allow

correct gap between switch head and functional lever

tab. Tighten jam nuts to secure adjustment. Jam nuts

should be torqued from

162 to 198 in--lb (18.4 to 22.4

N--m)

. After jam nuts are tightened, make sure that

clearance between head of switch and tab on the func-

tional lever has not changed.

4. After adjustment to the switch(es), use the Hand

Held Diagnostic Display to verify that neutral and mow

switches and circuit wiring are functioning correctly (see

Hand Held Diagnostic Display in the Troubleshooting

section of this chapter).

5. Secure console cover to console assembly (see

Control Console Assembly in the Service and Repairs

section of Chapter 7 -- Chassis).

1. Functional lever tab

2. Mow switch

3. Neutral switch

Figure 32

2

1

3

1. Functional lever tab

2. Mow switch

3. Neutral switch

4. Gap

Figure 33

2

1

3

4

1. Switch (mow shown)

2. Jam nut (2 used)

3. Lock washer (2 used)

Figure 34

162 to 198 in--lb

(18.4 to 22.4 N--m)

2

1

3

Elec

trica

l

System

Summary of Contents for Greensmaster 3420 TriFlex

Page 2: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 4: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 6: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 24: ...Greensmaster 3320 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3420 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3420 Page 4 20 Diesel Engine This page is intentionally blank ...

Page 56: ...Greensmaster 3320 3420 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 150: ...Greensmaster 3320 3420 Hydraulic System Page 5 96 This page is intentionally blank ...

Page 250: ...Greensmaster 3320 3420 Page 6 100 Electrical System This page is intentionally blank ...

Page 277: ...Greensmaster 3320 3420 Page 7 27 Chassis This page is intentionally blank Chassis ...

Page 325: ...Greensmaster 3320 3420 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 340: ...Greensmaster 3320 3420 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 347: ...Page 10 9 This page is intentionally blank ...

Page 356: ...Page 10 18 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Below 312000000 ...

Page 358: ...Page 10 20 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Above 312000000 ...

Page 360: ...Page 10 22 This page is intentionally blank ...