Greensmaster 3320/3420

Page 7 -- 17

Chassis

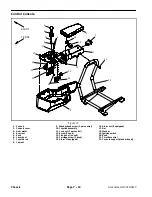

Disassembly (Fig. 13)

1. Park machine on a level surface, engage the parking

brake, lower the cutting units and stop the engine. Re-

move key from the ignition switch.

2. Remove screws (item 12) that secure console cover

(item 2) to console. Lower cover to allow access to con-

sole components.

3. Remove components from control console as need-

ed using Figure 13 as a guide.

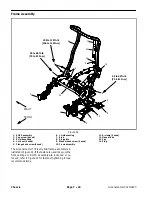

4. Disassemble functional control lever assembly as

needed using Figure 14 as a guide.

5. Disassemble joystick assembly as needed using

Figure 15 as a guide.

NOTE:

The alarm (item 15) is used on machines that

are equipped with the Turf Guardian

TM

Leak Detector

System.

NOTE:

Refer to Chapter 6 -- Electrical System for infor-

mation regarding electrical components on console.

Assembly (Fig. 13)

1. If functional control lever assembly was disas-

sembled, assemble control lever using Figure 14 as a

guide.

2. If joystick assembly was disassembled, assemble

joystick using Figure 15 as a guide. If finger spring wash-

ers (item 7 in Fig. 15) were removed, position washers

so that fingers on washer point towards pivot hub.

3. Install all removed components to control console

using Figure 13 as a guide.

4. Position console cover (item 2) to console and se-

cure with screws (item 12).

1. Console

2. Pivot tube

3. Functional lever

4. Split bushing

5. Cap screw

6. Flat washer

7. Lock nut

8. Roller pivot

9. Bushing

10. Flat washer

11. Spring spacer

12. Torsion spring

13. Flat washer

14. Lock nut

15. Bearing spacer (2 used)

16. Bearing

17. Lock nut

18. Spring pin

19. Ball joint

20. Neutral lock cable

21. Lock nut

22. Cable clamp

23. Neutral switch

24. Knob

25. Mow switch

26. Screw (2 used)

27. Screw (2 used)

28. Lock nut (2 used)

29. Clip (2 used)

30. Lever bracket

31. Jam nut (4 used)

32. Lock washer (4 used)

Figure 14

2

3

4

5

6

7

8

9

10

11

12

13

14

16

17

18

19

20

21

22

24

27

28

26

29

23

15

1

25

30

31

32

FRONT

1. Joystick rod

2. Jam nut

3. Joystick bracket

4. Switch (2 used)

5. Screw (2 per switch)

6. Spacer

7. Finger spring washer

8. Flat washer

9. Cap screw

10. Bushing

11. Pivot hub

12. Torsion spring

13. Speed nut (2 used)

14. Lock nut

Figure 15

2

3

6

8

9

10

11

13

1

5

7

12

14

4

7

10

Chas

sis

Summary of Contents for Greensmaster 3420 TriFlex

Page 2: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 4: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 6: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 24: ...Greensmaster 3320 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3420 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3420 Page 4 20 Diesel Engine This page is intentionally blank ...

Page 56: ...Greensmaster 3320 3420 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 150: ...Greensmaster 3320 3420 Hydraulic System Page 5 96 This page is intentionally blank ...

Page 250: ...Greensmaster 3320 3420 Page 6 100 Electrical System This page is intentionally blank ...

Page 277: ...Greensmaster 3320 3420 Page 7 27 Chassis This page is intentionally blank Chassis ...

Page 325: ...Greensmaster 3320 3420 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 340: ...Greensmaster 3320 3420 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 347: ...Page 10 9 This page is intentionally blank ...

Page 356: ...Page 10 18 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Below 312000000 ...

Page 358: ...Page 10 20 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Above 312000000 ...

Page 360: ...Page 10 22 This page is intentionally blank ...