Greensmaster 3320/3420

Page 6 -- 91

Electrical System

2. Disconnect the cutting units from the electrical power

supply by separating the cutting unit power disconnect

couplers (see Opening Electrical Circuit to Cutting Units

in the General Information section of this chapter). This

will prevent unexpected cutting unit operation.

3. To allow access to generator assembly, remove tank

mount plate assembly from machine (see Tank Mount

Plate Assembly in the Service and Repairs section of

Chapter 7 -- Chassis).

4. Remove generator drive belt (see Generator Drive

Belt (Greensmaster 3420) in this section).

5. Disconnect wire harness connector from generator

assembly.

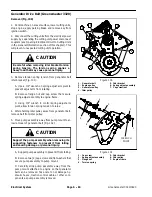

CAUTION

Support generator assembly when removing it to

prevent it from falling and causing personal inju-

ry. Assembly weighs approximately 50 pounds

(23 kg).

6. Support generator to prevent it from falling or shift-

ing.

NOTE:

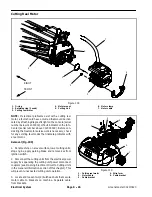

Upper two (2) generator mounting locations on

generator plate (item 5) are slotted.

7. Loosen upper two (2) flange head screws (item 6)

that secure generator assembly to generator plate.

Then, remove remaining three (3) screws (item 6) that

secure generator.

IMPORTANT: Make sure to not damage the genera-

tor, fuel lines, hydraulic hoses, electrical harness,

control cables or other parts while removing the

generator assembly.

8. Carefully raise generator assembly to disengage up-

per two (2) screws from generator plate. Then, remove

generator from machine.

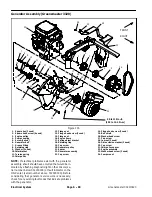

9. If necessary, remove generator pulley from genera-

tor shaft:

A. Remove cap screw (item 27) and spacer (item

25) that secure generator pulley to generator shaft.

B. Loosen the two (2) square head screws (item 4)

that secure the generator pulley to the generator

shaft.

C. Slide generator pulley from generator shaft. Lo-

cate and retrieve square key (item 2).

10.If generator disassembly is necessary, remove gen-

erator guard (item 29) from generator.

Installation (Fig. 106)

1. If removed, install generator pulley to generator

shaft:

A. Apply antiseize lubricant to generator shaft. Posi-

tion square key (item 2) into slot in shaft.

B. Slide generator pulley onto generator shaft.

Make sure that pulley flange is positioned towards

the generator.

C. Install and tighten spacer (item 25) and cap screw

(item 27) to secure generator pulley to generator

shaft.

D. Install two (2) square head screws (item 4) in gen-

erator pulley flange. Torque screws from

90 to 110

in--lb (10.2 to 12.4 N--m)

.

2. Install generator guard (item 29) if it was removed

from generator.

CAUTION

Support generator assembly when installing it to

prevent it from falling and causing personal inju-

ry. Assembly weighs approximately 50 pounds

(23 kg).

IMPORTANT: Make sure to not damage the genera-

tor, fuel lines, hydraulic hoses, electrical harness,

control cables or other parts while installing the

generator assembly.

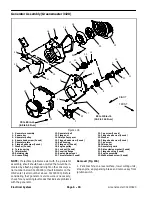

3. Loosely install upper two (2) flange head screws

(item 6) into generator assembly. Carefully position gen-

erator assembly to generator plate and engage upper

screws in generator plate slots.

4. Secure generator assembly to generator plate with

five (5) flange head screws (item 6).

5. Connect wire harness connector to generator as-

sembly.

6. Install generator drive belt (see Generator Drive Belt

(Greensmaster 3420) in this section). Make sure that

drive belt is properly tensioned.

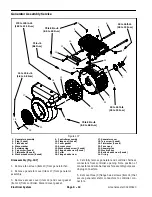

7. Install tank mount plate assembly to machine (see

Tank Mount Plate Assembly in the Service and Repairs

section of Chapter 7 -- Chassis).

8. Check hydraulic oil level in reservoir and adjust if

necessary.

9. Connect the cutting unit power disconnect couplers.

Elec

trica

l

System

Summary of Contents for Greensmaster 3420 TriFlex

Page 2: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 4: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 6: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 24: ...Greensmaster 3320 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3420 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3420 Page 4 20 Diesel Engine This page is intentionally blank ...

Page 56: ...Greensmaster 3320 3420 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 150: ...Greensmaster 3320 3420 Hydraulic System Page 5 96 This page is intentionally blank ...

Page 250: ...Greensmaster 3320 3420 Page 6 100 Electrical System This page is intentionally blank ...

Page 277: ...Greensmaster 3320 3420 Page 7 27 Chassis This page is intentionally blank Chassis ...

Page 325: ...Greensmaster 3320 3420 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 340: ...Greensmaster 3320 3420 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 347: ...Page 10 9 This page is intentionally blank ...

Page 356: ...Page 10 18 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Below 312000000 ...

Page 358: ...Page 10 20 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Above 312000000 ...

Page 360: ...Page 10 22 This page is intentionally blank ...