22

EN

ENGLISH

(Translation of the Original Instructions)

9 .9 .2

Air filter (Mod. B&S 8270) (29X)

1.

Carefully clean around the air filter cover

.

2.

Remove the air filter cover (29X:A) by un

-

screwing the two knobs (29X:B).

3.

Dismantle the filter assembly (29X:C). Extract

the pre-filter (29X:D).

4.

Clean the paper filter by tapping it gently

against a flat surface. If the filter is very dirty,

replace it.

5.

Clean the pre-filter. If the filter is very dirty,

replace it.

6.

Assemble the filter by performing the above

instructions in reverse order.

9 .9 .3

Air filter (Mod. B&S VANGUARD

18HP)

(27X)

1.

Carefully clean around the air filter cover.

2.

Remove the air filter cover (27X:A) by remo

-

ving the two clamps.

3.

Dismantle the filter assembly (27X:B). The

prefilter is placed over the air filter. Make sure

that no dirt gets into the carburettor. Clean the

air filter housing.

4.

Clean the paper filter by tapping it gently

against a flat surface. If the filter is very dirty,

replace it.

5.

Clean the pre-filter. If the filter is very dirty,

replace it.

6.

Assemble the filter by performing the above

instructions in reverse order.

9 .9 .4 Spark plug

Before removing the spark plug, clean around its

mounting.

For the type of spark plug and relative spark gap,

please refer to

“0 TECHNICAL DATA TABLE”

.

9 .9 .5 Air intake

See figure (26:A, 27:C,29X:E). The engine is air-

cooled. A blocked cooling system can damage the

engine. Clean the motor air intake. More meticulous

cleaning of the cooling system should be carried

out during each basic service.

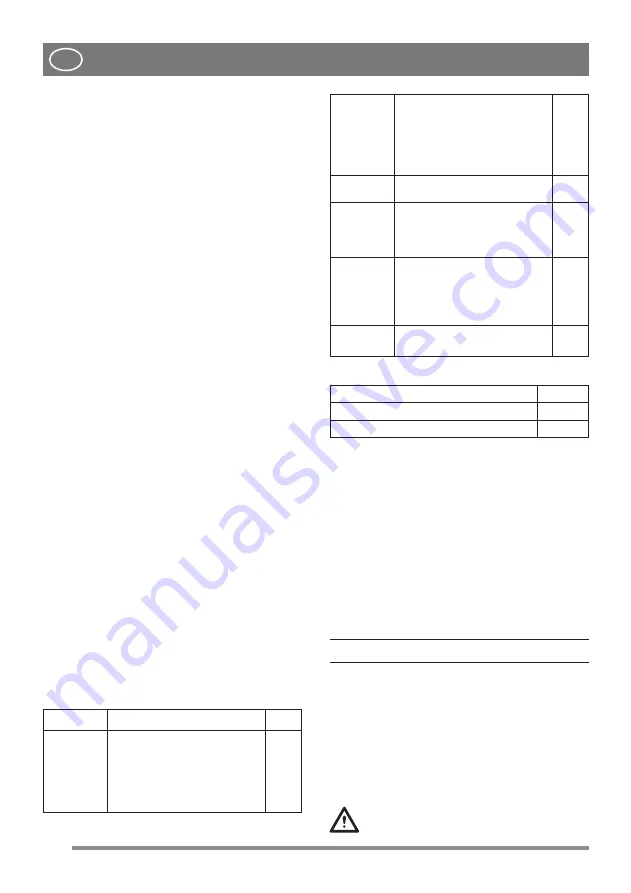

9 .10 LUBRICATION (28)

Object

Action

Fig

.

Centre

point

3 grease nipples located on

the central articulation on the

left-hand side of the machine.

Use a grease gun filled with

universal grease. Pump until

the grease seeps out.

28:A

Steering

wheel

2 grease nipples located on

the central articulation on the

left-hand side of the machine.

Use a grease gun filled with

universal grease. Pump until

the grease seeps out.

28:B

Tensioning

arms

Lubricate the support points

of the tensioning arms with oil.

28:C

Wheel

bearings

2 grease nipples.

Use a grease gun filled with

universal grease. Pump until

the grease seeps out.

28:D

Quick-

release

supports

1 grease nipple for each front

wheel.

Use a grease gun filled with

universal grease. Pump until

the grease seeps out.

28:E

Control

cables

Lubricate the control cable

ends with oil.

28:F

9 .10 .1 Fuses (31:F)

Destination

Fuse

Electrical system power supply

20 A

Battery charger power supply.

25 A

To replace the fuses, proceed as follows:

1. Close the fuel cock (24:B).

2. Open the bonnet (see 7.4).

3. Take the key out of the main power switch

(see 6.2).

4. Remove the engine casing (see 7.5.1).

5. Replace the damaged fuse.

6. Replace the engine caring (see 7.5.2).

7. Insert the key in the main power switch (only

if you intend to use the machine).

8. Close the bonnet.

9. Open the fuel cock (only if you intend to use

the machine).

10 ASSISTANCE AND REPAIRS

This manual provides all the necessary informa-

tion to run the machine and for correct basic main-

tenance operations which can be performed by

the user. Any regulations and maintenance opera-

tions not described herein must be carried out by

your Dealer or Authorized Service Centre, which

have the necessary knowledge and equipment

to ensure that the work is carried out correctly,

maintaining the correct degree of safety and the

original operating conditions of the machine.

Before performing any servicing opera-

tions:

Summary of Contents for P 901 PH

Page 2: ......

Page 5: ...A E H F B C D 5 A B C 8 B C A 7 6 A A 740 IOX 540 IX 340 IX 740 IOX 540 IX III ...

Page 6: ...D C B A E 13 A A B C 11 A OFF ON 12 A C B 10 A D C B 9 IV ...

Page 8: ...A B OFF ON 24 23 A B 740 IOX 540 IX 20 19 A 22 B C A 21 VI ...

Page 10: ...E F F D F C B A A A B 28 VIII ...

Page 11: ...A B A C 30 1 3 32 F D C 20A 25A E B A 31 IX ...

Page 12: ......

Page 20: ...XVIII ...

Page 50: ......

Page 108: ......

Page 172: ...STIGA S p A Via del Lavoro 6 31033 Castelfranco Veneto TV ITALY dB LWA Type s n Art N ...