Summary of Contents for e510 series

Page 1: ......

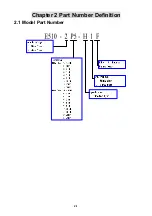

Page 8: ...2 1 Chapter 2 Part Number Definition 2 1 Model Part Number...

Page 13: ...3 4 Screw M4 Screw M4...

Page 34: ...3 25 c Three phase 200V 8 10HP 400V 8 15HP E510 Frame 3 E510 Frame 3 NEMA1...

Page 35: ...3 26 d Three phase 200V 15 20HP 400V 20 25HP E510 Frame 4 E510 Frame 4 NEMA1...

Page 43: ...3 34 3 5 2 Single Three phase Model 200V E510 2P5 H E510 201 H E510 202 H E510 203 H...

Page 197: ......