1 - 25

Chapter 3 Removal and Replacement Procedures (RRPs)

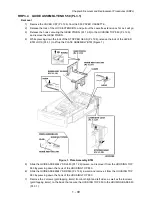

When installing the PLATE ASSEMBLY BTM, be sure to put 2 SPRING BTM UP 150s

(PL 2.1) into the bosses on the back of the PLATE ASSEMBLY BTM (NOTE 1) (Figure 2).

Be sure to put 2 claws on the top of the PLATE ASSEMBLY BTM under the hooks on the

HOUSING TOP 150.(NOTE 2) (Figure 2).

3)

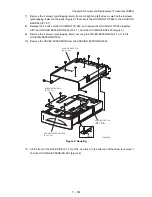

Install the GEAR PB R (PL 2.1) to the SHAFT PB, and secure it with the hook.

Be sure to install the hook of the GEAR PB R into the groove of the SHAFT PB.

When installing the GEAR PB R, be sure to lift up the PLATE ASSEMBLY BTM. If the

PLATE ASSEMBLY BTM is inclined, a paper skew or jam may occur. Check after the

installation is completed.

4)

While pressing down the hook of the HOUSING TOP 150, install the GUIDE ASSEMBLY SD R150

(PL 2.1) to the HOUSING TOP 150.

After installing, make sure that the 3 claws of the GUIDE ASSEMBLY SD R150 sit cor-

rectly in the grooves of the HOUSING TOP 150.

5)

While pressing down the hook of the HOUSING TOP 150, install the GUIDE ASSEMBLY SD L150

(PL 2.1) to the HOUSING TOP 150

After installing, make sure that the 3 claws of the GUIDE ASSEMBLY SD L150 sit cor-

rectly in the grooves of the HOUSING TOP 150.

6)

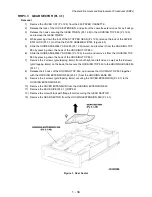

Push the PLATE ASSEMBLY BTM downward to lock.

7)

Install the GEAR PINION (PL 2.1) to the HOUSING TOP 150.

When installing the GEAR PINION, make sure the GUIDE ASSEMBLY SD R150 and

GUIDE ASSEMBLY SD L150 are completely opened. If not, the side register may be mis-

aligned.

8)

Install the COVER CST (PL 2.1) to the 150 PAPER CASSETTE.

Summary of Contents for 9045N

Page 1: ...Laser Printer TallyGenicom 9045N Service Manual J20006AA ...

Page 16: ...xv Blank Page ...

Page 20: ...Chapter 1 Troubleshooting Chapter 1 Troubleshooting CONTENTS Blank Page ...

Page 88: ...1 68 Chapter 1 Troubleshooting Blank Page ...

Page 160: ...1 140 Chapter 1 Troubleshooting Blank Page ...

Page 162: ...1 142 Chapter 1 Troubleshooting Blank Page ...

Page 164: ...Chapter 2 Printer Diagnostics Chapter 2 Diagnostics CONTENTS 11 Print Summary 2 16 ...

Page 194: ...1 10 Chapter 3 Removal and Replacement Procedures RRPs RRP2 150 PAPER CASSETTE ...

Page 213: ...1 29 Chapter 3 Removal and Replacement Procedures RRPs RRP3 550 PAPER CASSETTE ...

Page 240: ...1 56 Chapter 3 Removal and Replacement Procedures RRPs RRP4 150 paper Feeder ...

Page 257: ...1 73 Chapter 3 Removal and Replacement Procedures RRPs RRP5 550 Paper Feeder ...

Page 277: ...1 93 Chapter 3 Removal and Replacement Procedures RRPs RRP6 Xerographics ...

Page 302: ...1 118 Chapter 3 Removal and Replacement Procedures RRPs RRP7 500 Paper Exit ...

Page 322: ...1 138 Chapter 3 Removal and Replacement Procedures RRPs RRP8 Frame Drive ...

Page 331: ...1 147 Chapter 3 Removal and Replacement Procedures RRPs RRP9 Electrical ...

Page 394: ...1 210 Chapter 3 Removal and Replacement Procedures RRPs ...

Page 454: ...1 270 Chapter 3 Removal and Replacement Procedures RRPs Blank Page ...

Page 459: ...4 3 Chapter 4 Plug Jack P J Connector Locations Blank Page ...

Page 465: ...4 9 Chapter 4 Plug Jack P J Connector Locations 3 2 OCT Option P J Diagram ...

Page 468: ...4 12 Chapter 4 Plug Jack P J Connector Locations Blank Page ...

Page 470: ...Chapter 5 Parts Lists Chapter 5 Parts Lists CONTENTS Blank Page ...

Page 479: ...5 9 Chapter 5 Parts List Blank Page ...

Page 483: ...5 13 Chapter 5 Parts List Blank Page ...

Page 490: ...5 20 Chapter 5 Parts List PL 7 2 500 PAPER EXIT 2 2 OPTION FACE UP TRAY ILLUSTRA TION ...

Page 496: ...5 26 Chapter 5 Parts List OPTIONS PL 10 1 OPTION DUPLEX ILLUSTRATION ...

Page 501: ...5 31 Chapter 5 Parts List Blank Page ...

Page 529: ...6 19 Chapter 6 Principles of Operation J26119AA EP CARTRIDGE BTR ASSY ...

Page 531: ...6 21 Chapter 6 Principles of Operation LD Assembly JG6121AA SOS PWB Scanner Assembly ...

Page 535: ...6 25 Chapter 6 Principles of Operation ...

Page 558: ...6 48 Chapter 6 Principles of Operation Blank Page ...

Page 584: ...7 24 Chapter 7 Wiring Diagrams and Signal Information Blank Page ...

Page 608: ...Chapter 9 ESS Options Chapter 9 Controller ESS Options Contents Blank Page ...