PowerSync Analyzer Reference Manual

March 9, 2010

Sifos Technologies page

15

The Detection resistance and capacitance ranges in the Detection subsystem are 9 K

Ω

-39 K

Ω

Ohms, and nominally 0,

5, 7, and 11

μ

F respectively. Newer “Type 2” or “Type 3” PSE Test Blades add capacitance values of 47, 52, 54, and 58

μ

F to aid with legacy PD emulation needs. The AC MPS signature consists of 24 K

Ω

in parallel with 0.1

μ

F that

becomes visible above 11 volts – the same level where Detection Signature passives are removed and become invisible.

Because of the 11 volt activation floor, the effective DC resistance of the AC MPS signature is significantly greater than

24 K

Ω

until the port voltage significantly exceeds 11V. This means that neither the Detection Signature nor the AC

MPS signature will produce any measurable error to Classification Signature loads created by the Active Load module.

There are 2 forward-biased diodes that the signal must pass through before entering the Detection and MPS passives

circuitry. These model typical PD bridge characteristics and are commensurate with recommended circuitry as

described in the 802.3 PoE standard.

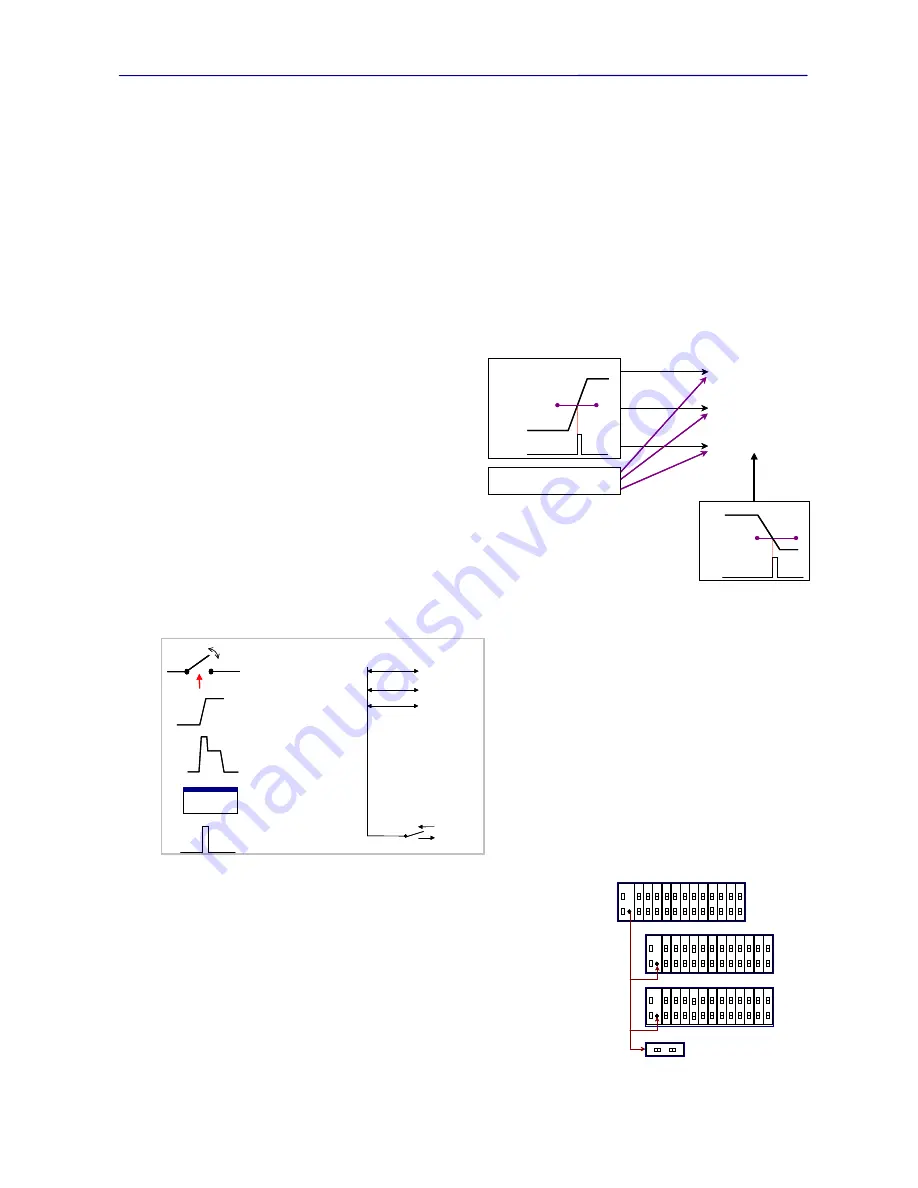

2.3.2. Triggers

The PowerSync Analyzer has extensive triggering capabilities, which are divided into 2 categories:

internal (or

waveform)

and

external (or event)

. The instrument also has the ability to perform non-triggered measurements. The

triggering types are depicted in Figures 2.7 and 2.8. Also

depicted in Figure 2.7 are trigger applications including

the DC meters, time-interval measurement, and load

current transient, each of which can be initiated with

those triggers.

Internal (or waveform) triggering is derived from the

common mode voltage levels received from the PSE

under test. For most measurements, this triggering is

based upon the trigger levels and directions (rising or

falling) set for

Trigger 1

. A second trigger,

Trigger 2

is

used exclusively for terminating time interval

measurements. Trigger 2 offers identical

programmability as Trigger 1 (levels and edge polarities).

External (or Event) triggering is also used to initiate

measurements or actions, and is initiated by either a user

command, an action that is programmed to send out an

external trigger, or through an external event that appears

on the trigger bus. The trigger bus is a trigger signal

connection that is shared by all ports within a system, and

by the Trig Out BNC connector on each PowerSync

Analyzer. Figure 2.8 shows the sources used to generate

External (or event) triggers on the left, and shows the

external bus configuration on the right.

Any External trigger in the system will appear on this bus,

and will trigger any

port which is

waiting for an external trigger event. This enables cross-triggering across ports

and triggering via externally generated signals. It also enables the user to use the

trigger output for other purposes, such as monitoring data throughput during PSE

powering or load transients.

The BNC trigger connector on the Chassis Controller front panel can be

configured as an output or an input. As an output, it directly mirrors the External

trigger bus. Output triggers will appear as a 3.3V, 10 mSec pulse. When set as

an input, it can drive the external trigger bus inside the PSA chassis. This

enables triggering across multiple instruments, which may be desirable when

testing equipment with more than 24 ports.

Vo

lt

a

g

e

Trigger 1

Level

DC Meters

Current Transient

Time Interval Meter

Internal Trigger

External Trigger

Vo

lt

a

g

e

Trigger 2

Level

Trigger 2

Vo

lt

a

g

e

Trigger 1

Level

DC Meters

Current Transient

Time Interval Meter

Internal Trigger

External Trigger

Vo

lt

a

g

e

Trigger 2

Level

Trigger 2

Figure 2.7

Test Port Triggering

Port Switch

(Connect or Isolate)

Cu

rre

nt

Cu

rre

n

t

Static Load Change

Load Transient

Software “TrigOut”

(or Send Trigger)

> trigout

Another Port

5 Sources

External

Trigger Bus

Slot1, Port1

Slot1, Port2

Slot2, Port1

…..

Chassis

Ext. Trigger

(Optional)

(Optional)

(Optional)

Port Switch

(Connect or Isolate)

Cu

rre

nt

Cu

rre

n

t

Static Load Change

Load Transient

Software “TrigOut”

(or Send Trigger)

> trigout

> trigout

Another Port

5 Sources

External

Trigger Bus

Slot1, Port1

Slot1, Port2

Slot2, Port1

…..

Chassis

Ext. Trigger

(Optional)

(Optional)

(Optional)

Figure 2.8

PSA Test Port Trigger Sources

PSA #1

PSA #2

PSA #3

PSA #4

E

x

ter

n

a

l T

ri

gger

PSA #1

PSA #2

PSA #3

PSA #4

PSA #1

PSA #2

PSA #3

PSA #4

E

x

ter

n

a

l T

ri

gger

Figure 2.9

External Trigger Bus

Summary of Contents for PowerSync PSA100

Page 26: ...PowerSync Analyzer Reference Manual March 9 2010 Sifos Technologies page 26 ...

Page 56: ...PowerSync Analyzer Reference Manual March 9 2010 Sifos Technologies page 56 ...

Page 84: ...PowerSync Analyzer Reference Manual March 9 2010 Sifos Technologies page 84 ...

Page 110: ...PowerSync Analyzer Reference Manual March 9 2010 Sifos Technologies page 110 ...

Page 120: ...PowerSync Analyzer Reference Manual March 9 2010 Sifos Technologies page 120 ...