2-17

After Processing

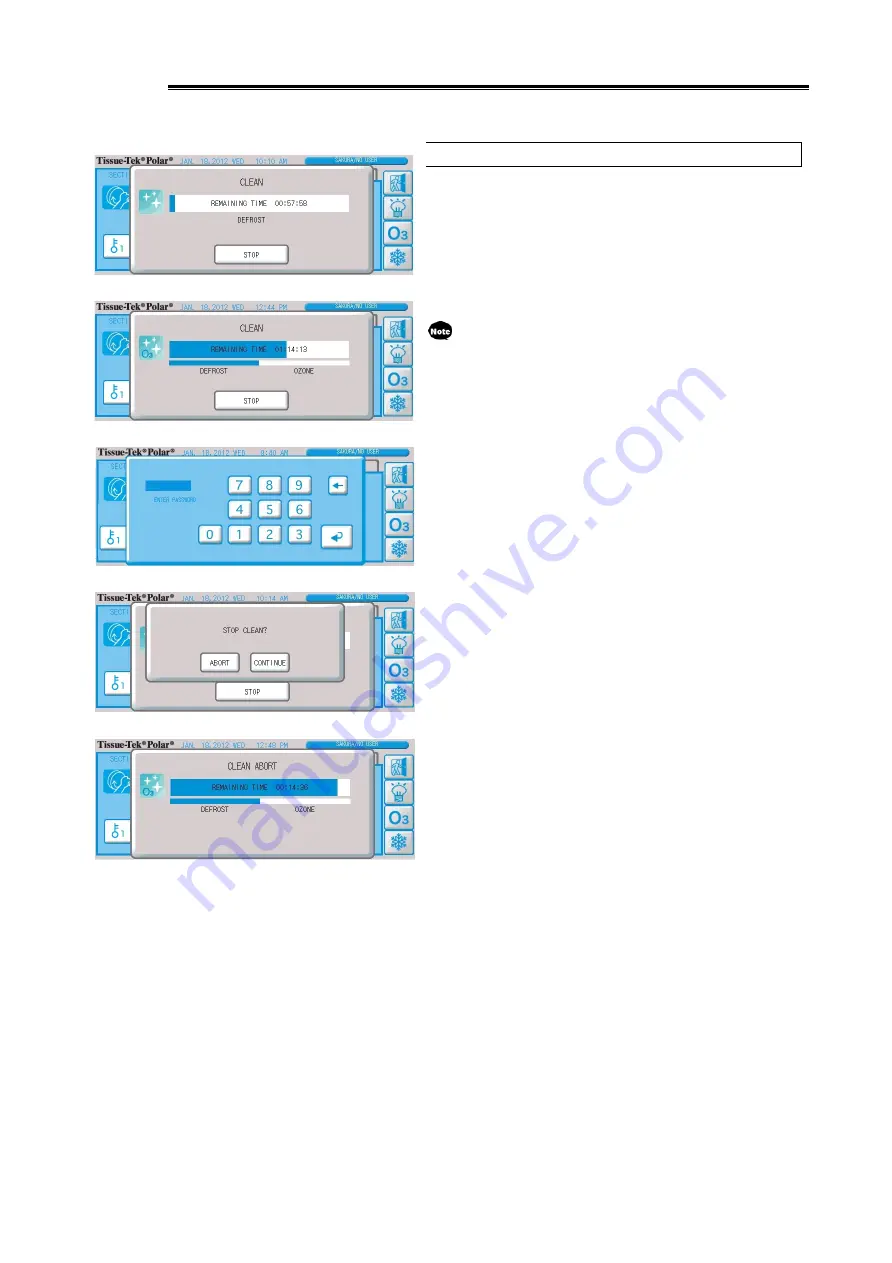

Cancelling Cleaning Operation

1. To cancel cleaning operation, you must enter the password.

2. Pressing the "Stop" button displays the cleaning operation

cancellation password confirmation screen.

Once the correct password is entered, the cleaning operation

cancellation confirmation screen appears.

If cleaning operation ends while this screen is displayed, the

screen closes automatically.

This password entry screen is for aborting the cleaning

operation, not for logging on the system.

3. Select "Abort," and defrost cycle operation will be cancelled if

the cleaning operation consists of the defrost cycle only, after

which the screen will close.

If the ozone cycle is also set as part of the cleaning operation,

the cleaning operation cancellation screen will appear and the

ozone cycle will be cancelled. However, the ozone purge cycle

cannot be cancelled.

Summary of Contents for Tissue-Tek Polar DM

Page 1: ...Operating Manual Frozen Tissue Section Preparation Instrument Cryostat Microtome...

Page 15: ...Chapter 1 Basic Knowledge of Instrument...

Page 32: ...1 17 Standard Accessories Options 4 5 15...

Page 68: ...1 53...

Page 69: ...Chapter 2 Operating Method...

Page 108: ...2 39...

Page 109: ...Chapter 3 Maintenance Inspection...

Page 122: ...3 13...

Page 123: ...Chapter 4 Troubleshooting...