76

GX-400

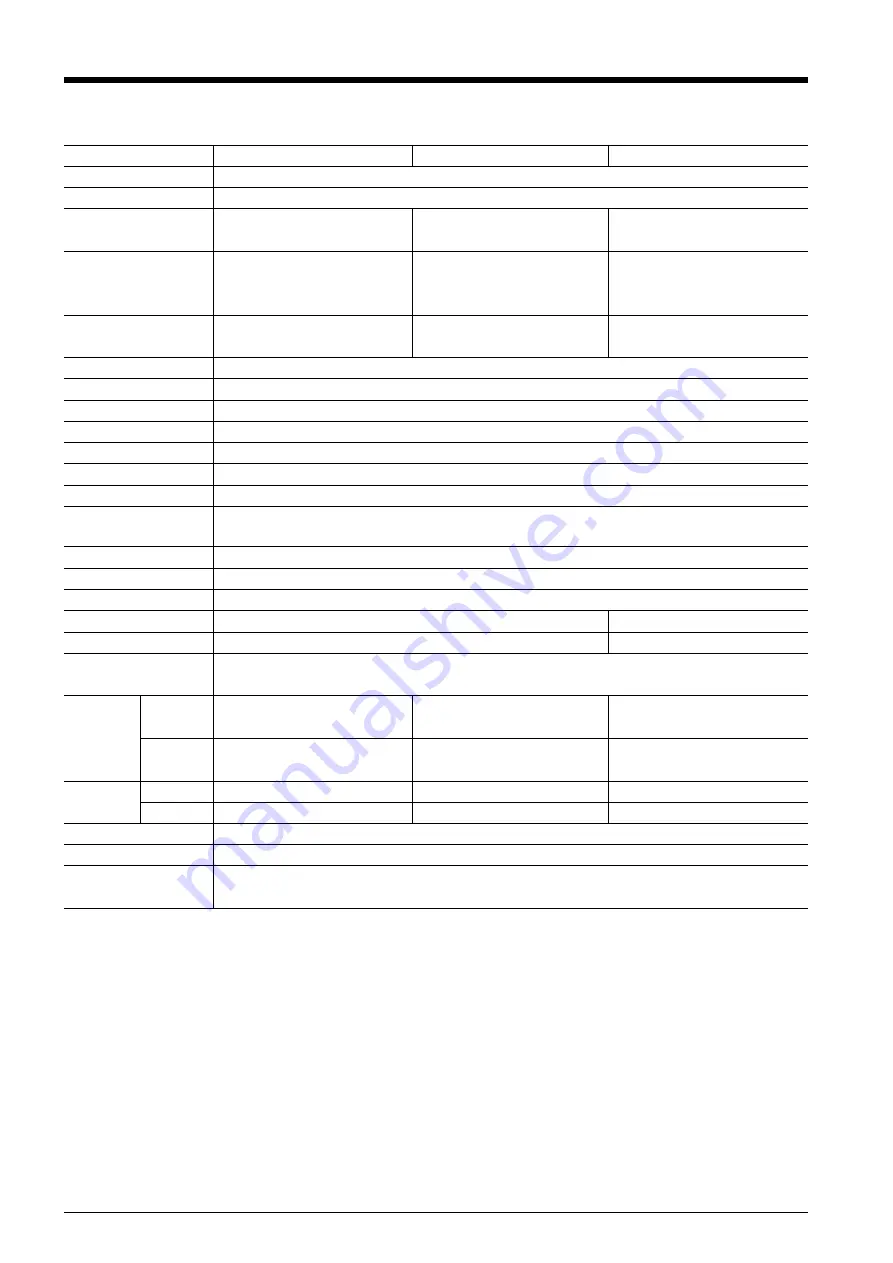

Mechanism

Driving method

Maximum cutting area

Acceptable media widths

Width of material that

can be cut off

Tools

Maximum cutting speed

Cutting speed

Blade force

Mechanical resolution

Software resolution

Distance accuracy

(*1)

Repetition accuracy

(*1)(*2)(*3)

Interface

Replot memory

Instruction system

Power supply

Power consumption

Acoustic noise level

Dimensions

Weight

Operating temperature

Operating humidity

Accessories

Special blade for CAMM-1 series

During cutting: 850 mm/sec. (in all directions) During tool-up: 1202 mm/sec. (in 45

°

direction)

10 to 850 mm/sec. (in increments of 10 mm/sec.)

20 to 350 gf

0.0125 mm/step (0.000492 in./step)

0.025 mm/step (0.000984 in./step)

Error of less than

±

0.2% of distance traveled, or 0.1 mm (0.00394 in.), whichever is greater

0.1 mm or less

Serial (RS-232C-compatible), USB (Rev 1.1)

2 MB (buffer size: 8 MB)

Dedicated system (CAMM-GLIII-compatible)

AC 100V to 240V

±

10% 50/60 Hz 1.2A

AC 100V to 240V

±

10% 50/60 Hz 1.1A

Cutting mode: 62dB (A) or less Standby mode: 40dB (A) or less

(according to ISO 7779)

Width: 737 mm (29 in.)

Length: 24998 mm (984-1/8 in.)

Min. 50 mm (2 in.)/ Max. 915 mm (36 in.)

(50 to 540 mm (2 in. to 21 in.),

582 to 915 mm (23 in. to 36 in.))

0 to 812 mm (0 in. to 32 in.)

GX-300

Main unit

With stand

Main unit

With stand

*1

According to material and cutting conditions as specified by Roland DG Corp. (refer to the following page).

*2

Excluding stretching/contraction of the material

*3

Range for assured repetition accuracy

For materials with a width exceeding 610 mm (24 in.): Length 4,000 mm (157-7/16 in.) (GX-500/400 only)

For materials with a width of 610 mm (24 in.) or less : Length 8,000 mm (314-15/16 in.)

Width: 1000 mm (39 in.)

Length: 24998 mm (984-1/8 in.)

Min. 90 mm (3-1/2 in.) /

Max. 1178 mm (46 in.)

0 to 1067 mm (0 in. to 42 in.)

Width: 1195 mm (47 in.)

Length: 24998 mm (984-1/8 in.)

Min. 90 mm (3-1/2 in.) /

Max. 1372 mm (54 in.)

0 to 1270 mm (0 in. to 50 in.)

GX-500

Media-movement method

Digital control servo motor

1144 mm (W) x 264 mm (D) x 398 mm (H)

(45-1/16 in. (W) x 10-3/8 in. (D) x 15-11/16 in. (H))

1144 mm (W) x 727 mm (D) x 1113 mm (H)

(45-1/16 in. (W) x 28-5/8 in. (D) x 43-13/16 in. (H))

26 kg (57.3 lb.)

44 kg (97 lb.)

1407 mm (W) x 264 mm (D) x 398 mm (H)

(55-3/8 in. (W) x 10-3/8 in. (D) x 15-11/16 in. (H))

1407 mm (W) x 727 mm (D) x 1113 mm (H)

(55-3/8 in. (W) x 28-5/8 in. (D) x 43-13/16 in. (H))

31 kg (68.3 lb.)

51 kg (112.4 lb.)

1602 mm (W) x 264 mm (D) x 398 mm (H)

(63-1/16 in. (W) x 10-3/8 in. (D) x 15-11/16 in. (H))

1602 mm (W) x 727 mm (D) x 1113 mm (H)

(63-1/16 in. (W) x 28-5/8 in. (D) x 43-13/16 in. (H))

35 kg (77.2 lb.)

55 kg (121.2 lb.)

5 to 40

°

C (41 to 104

°

F)

35 to 80% (non-condensing)

Power cord, blade holder (XD-CH2), pin, blade, alignment tool, cable clamp, replacement blade for separating knife,

USB cable, Roland software package CD-ROM, setup guide, user’s manual

9-2 Specifications

Approx. 100W

Approx. 95W

Summary of Contents for Camm-1 Pro GX-300

Page 9: ...To Ensure Safe Use 7...

Page 16: ...14...

Page 54: ...52...

Page 66: ...64...

Page 70: ...68...

Page 81: ...79...

Page 82: ...80...

Page 83: ......

Page 84: ...R3 070216...