9

Subject to change without notice

I n t r o d u c t i o n

LEVEL

TRIGGER

TRIG’d

SLOPE

AUTO

NORM

TYPE

SOURCE

FILTER

SLOPE

SINGLE

28

C

29

30

33

31

34

35

36

32

SCALE

TIME / DIV

X-POSITION

HORIZONTAL

TB/Z

MEM

O

R

Y

MENU

ACQUIRE

RUN

STOP

SET

CLR

37

D

38

37

41

39

42

43

44

40

the optional logic probes

24

25

. There are also the mathematics

function key

26

and the reference signal settings key

27

.

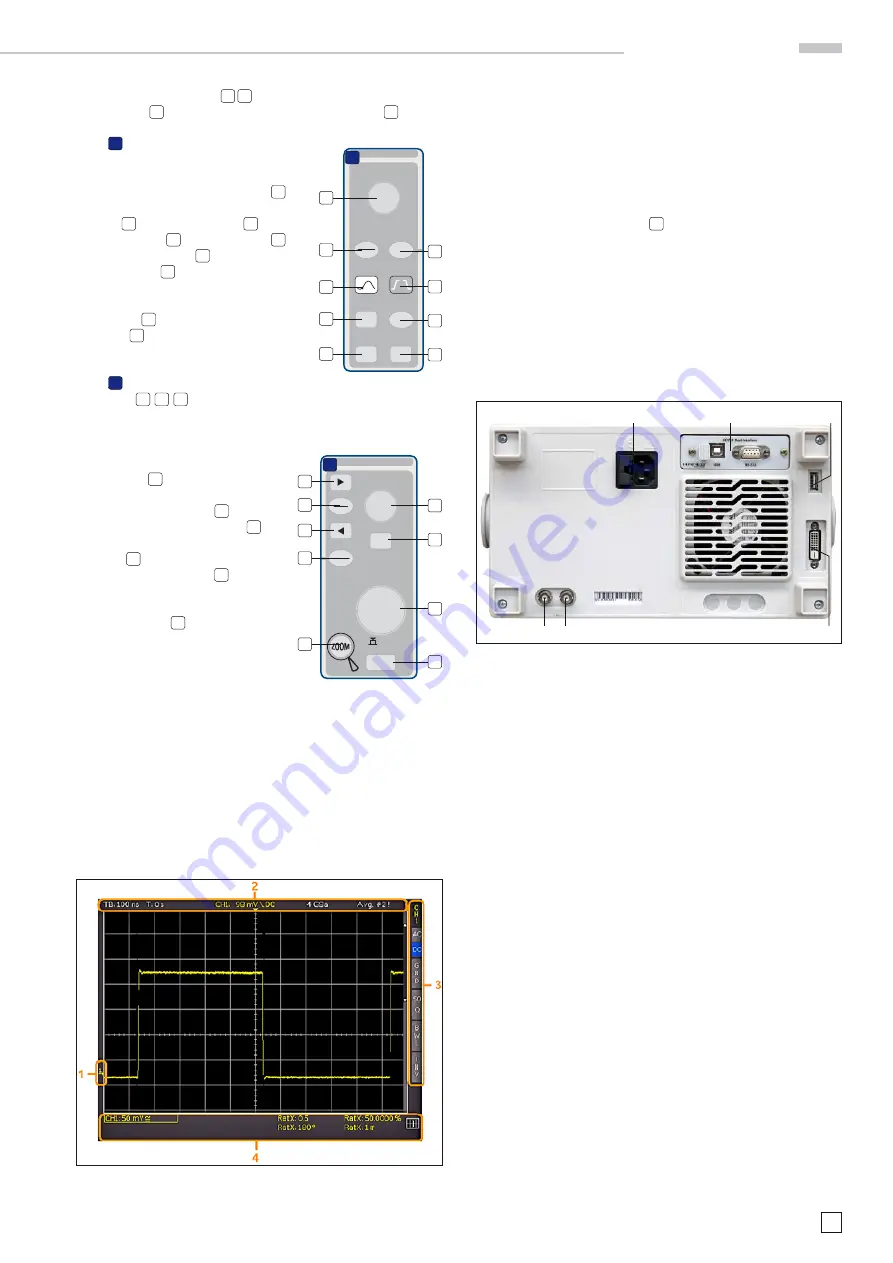

Area

C

:

This area TRIGGER of the control

panel offers all functions for the

adjustment of the trigger level

28

, the selection of auto or normal

trigger

29

, the trigger type

31

, the

trigger source

32

, single sweep

33

, the trigger slope

34

, the trigger

signal fi lters

36

. In addition, the-

re are status indicators showing

whether a signal fulfi lls the trigger

conditions

30

and which slope was

selected

34

.

Area

D

:

The keys

37

38

39

on this control

panel area HORIZONTAL allow to

shift the trigger position horizontal-

ly, either step-by-step or using the

smaller one of the knobs. The back-

lighted key

39

controls the run or

stop modes; the key will light up red

in stop mode. The key

40

activates

the zoom function, the key

44

the

selection of the acquisition modes,

the key

42

the access to the time

base menus. The knob

43

allows to

adjust the time base speed.

To the left of the control panel there

are the soft keys

2

which control the

menu functions.

2.3. Screen

The HMO is equipped with a 6.5“

(16.5 cm) LED backlighted colour

TFT display with VGA resolution (640

x 480 pixels). In normal mode (no menus shown) there are 12

divisions in X direction. If menus are shown, this will be redu-

ced to 10 divisions. On the left of the screen area little arrows

[1]

indicate the reference potentials of the channels. The line

above the graticule contains status and settings information

such as the time base speed, the trigger delay and other trigger

conditions, the actual sampling rate, and the acquisition mode

[2]

. On the right of the graticule a short menu is shown which

Fig. 2.4: Area C of the

control panel

Fig. 2.5: Area D

of the control panel

contains the most important settings of the channel actually

being displayed; these may be selected using the soft keys

[3]

.

Below the graticule, measurement results of parameters and

cursors, the settings of the activated vertical channels, of the

reference signal, and of the mathematically derived curves

[4]

are shown. Within the graticule, the signals of the selected chan-

nels are displayed. Normally, 8 vertical divisions are shown; it

can be virtually extended to 20 divisions which can be displayed

using the SCROLL BAR knob

5

.

2.4. Rear

view

On the rear panel there are the mains connector

[1]

, the re-

ceptacle for the interface modules

[2]

(USB / RS-232, Ethernet,

IEEE-488), the standard DVI connector

[3]

for the connection

of external monitors and projectors, the BNC connector for

the Y output

[4]

(of the channel selected for triggering) and the

external trigger input

[5]

. With the two-channel models this

connector is located on the front panel.

Fig. 2.7: Rear panel of the HMO3524

2.5. Options

The HMO352x series instruments offer some options which

allow you to extend the areas of application considerably. The

following interface modules are available and may be installed

by the customer in the rear receptacle:

– HO740 (IEEE-4888, GPIB, galvanically isolated)

– HO730 (combination of Ethernet and USB with integrated

web server)

All HMO 352x series instruments are prepared for mixed-

signal operation and have the appropriate connectors on the

front panel. Each of these connectors can be connected to an

8-channel logic probe HO3508, hence a maximum of 16 logic

channels is possible. More available options are the passive

500MHz slimline10:1 probes HZ355, the 19inch rack kit HZ46

and the carrying bag HZ99.

2.6. General concept of instrument operation

HAMEG oscilloscopes are renowned for easy operation, based

on a few basic principles which repeat with the diverse settings

and functions.

– Such keys which do not open a soft menu (e.g. Quickview)

switch a function on, pushing the key again will switch the

function off.

– Such keys which call a specifi c function (e.g. FFT) which

in turn can call or require more settings will activate the

function upon the fi rst touch. Pushing the key a second time

will call the soft menu (sub menu) for the settings. Pushing

the key a third time will deactivate the function.

[1]

[2]

[2]

[5] [4]

[3]

Fig. 2.6: Screen