Pratt & Whitney Rzeszów S.A.

MAINTENANCE MANUAL

PZL-10W ENGINE

79-02-00

1992.08.28

Page 2

Export Control Classification: PL/UE 9E999

B.

Scavenge line.

Oil drained to particular engine oil areas Is scavenged by four-section scavenge pump (17) and

transported to the oil tank ( 2 ) .

Inside tour ducts scavenging the oil from engine areas magnetic plugs (15) are installed and coarse

filters (14). The oil is scavenged from each area by the individual pump section and is then

transported by one common tube to the oil tank On its way from the pump to the oil tank oil flows

through the chip detector (13), dust separator nose section (1), thermovalve (8) and oil cooler (9). At

the scavenge pump outlet the shut-off valve (18) is installed to protect oil areas against overfilling

with oil after engine shut-down.

C.

Venting line.

The venting line includes accessory gearbox and compressor rotor rear bearing oil areas venting by

connecting these areas with the atmosphere via centrifugal air separator (4). The oil-air mist is

separated there for air and oil. The oil drains to accessory gearbox sump and the air is vented

through the external tube to the exhaust nozzle and than to the atmosphere.

The oil tank is vented separately on the helicopter vent system.

3. Description of the oil system main components.

A.

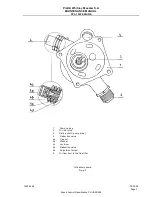

Oil delivery pump (see Dwg.2).

The oil delivery pump is a one section gear pump.

It contains one reduction valve (4) serving for pressure adjustment at the pump outlet. Oil inlet stub

(2) is located on the pump casing and on the pump mounting flange the oil outlet duct to fine filter is

located.

The delivery pump is mounted on the front wall of the accessory gearbox.

B.

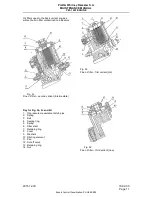

Oil scavenge pump (see Dwg. 3).

The oil scavenge pump is a gear type pump consisting of four sections each one scavenging the oil

from different oil area of the engine.

On the rear wall of the pump the shut-off valve (9) is mounted having the oil outlet stub (3) to the oil

tank.

The¡scavenge pump is mounted on the rear wall of the accessory gearbox.

C.

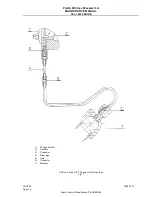

Oil fine filter (see Dwg. 5).

In the delivery line behind the delivery pump there is a fine filter with the contamination indicator.

It consists of filtering elements (12) installed on the filter cage (5) and the cup (14) collecting the

contaminations to be removed during filter inspections. The assembly of filtering elements and the

cup are secured by the ring (16) and pressed by the spring (4).