Pratt & Whitney Rzeszów S.A.

MAINTENANCE MANUAL

PZL-10W ENGINE

72-32-00

1997.02.28

Page 602

Export Control Classification: PL/UE 9E999

In order to perform the inspection it is necessary to remove all devices (equipment) on compressor inlet (inlet dust

separator, oil tank, inlet duct).

(3)

Through inspection openings in compressor case.

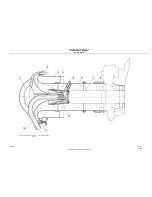

There are 14 (in 7 at left and right side of engine) inspection openings in the compressor case, which enable to

insert a terminal (probe) of endoscope or the other device in order to inspect six (6) axial stages as well as inducer

of compressor rotor centrifugal stage. The inspections openings, which are located between two adjacent vanes of

vane assembly on each compressor's stage, make possible to inspect the I + VI stage compressor rotor blades as

well as the centrifugal stage inducer blades.

Inside diameters of the inspection openings allow to insert into them the endoscope probe (tip) of diameter about 6

mm (0.24 in).

NOTES:

1.

When evaluation as well as blending of damaged blades are being made, use the

sketches shown in Dwg 601 and Dwg 602 too.

2.

The quantity of damaged blades is not limited. However, one has to take into

consideration that increased number of damaged blades causes the (reduction) decrease

of compressor efficiency, so also deterioration of engine's performance.

.3.

When blending the blades, take into consideration that the blending - polishing motion

shall be done along the blade's airfoil, and (fillet) junction of blended areas shall be

smooth.

CAUTION:

IF DAMAGES ON THE BLADES ARE WORSE THAN ACCEPTABLE (PERMISSIBLE)

DAMAGES (ARE OUT OF TOLERANCE), THE ENGINE SHALL BE REMOVED FROM A

HELICOPTER AND SHIPPED TO AUTHORIZED OVERHAUL WORKSHOP ORTO

ENGINE'S MANUFACTURER FACILITIES.

B.

Inspection of Inlet Guid Vanes and l-st Stage Compressor Rotor Blades Through Inspection Opening in

Compressor Air Inlet Duct.

NOTES:

1.

During inspection use inspection lamp or the other portable light source of voltage no bigger than

30V and which will enable to light all parts of circumference of blade-ring.

2.

inspection of the part of blade-ring invisible from inspection opening is possible when using

mirror fastened on the suitable extension arm.

(1)

Remove the cover of inspection opening from inlet duct-in accordance with Helicopter Maintenance Manual.

(2)

Using the additional light source and the mirror, inspect inlet guide vanes as well as inlet duct. Pay a special

attention if there are any mechanical damages of blades and internal surface of inlet duct as well as any

foreign matter in inlet duct.