Pratt & Whitney Rzeszów S.A.

MAINTENANCE MANUAL

PZL-10W ENGINE

1992.08.28

72-32-00

Page 605

Export Control Classification: PL/UE 9E999

(a)

rotating compressor rotor by a crank move damaged blade assigned for blending into the

most suitable position for that operation.

(b)

lock compressor rotor agaist its rotation using a wooden or rubber key, inserting it between

inlet guide vanes and pay attention not to cause deformation of vanes.

(c)

insert a clean cloth into compressor flow path by this way protecting its against penetration

of chips and any other elements into it.

(d)

blend damage using a file (Table 202, item 17) or the other tool and polish it by abrasive

paper (Table 202, item 16) ensuring smooth transition (fillet) along blade and not enlarging

the depth over the depth of damage being blended.

(e)

polish all ground areas using felt with polishing powder or diamond compound (see 72-02-

00, Table 202, item 14, 15).

NOTE:

When a bend of blade's corner is found, that bend shall be removed by filing and

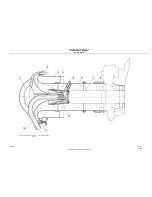

blending as it is shown in Dwg 602.

(f)

after blending of damages carefully remove the cloth from compressor flow path and locking

key as well as make sure there is no chips or any other elements inside flow path.

(g)

remove crank and screw the protective cover into engine< front case in the same manner as

for compressor rotation check (see item 1).

(h)

install, in accordance with Helicopter Maintenance Manual all devices (equipment) on

compressor inlet, which were removed per item 2.C.

E.

Inspection of Compressor Rotor Blades Through Inspection Openings.

(1)

Inspection of blades through inspection openings is performed mainly in

two cases:

(a)

as periodical, scheduled inspection of l-st. and ll-nd stage compressor rotor blades, which

main purpose is only to find evidence of blade's damages with no necessity of (it depends on

usability of used endoscope) evaluation of their location and sizes. In the case these

damages are found and there ase no possibility to establish their location and sizes, inspect

these blades through compressor air inlet duct (item 2.C.) and evaluate if they are permitted

according to specified criteria of item 2.C.