131

Cleaning steps for protection glass of laser emission port (Daily maintenance)

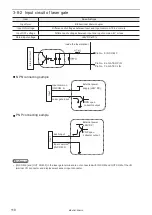

In order to maintain stable marking quality, the protection glass of laser emission port needs to be cleaned regularly

according to the usage environment.

1.

Turn OFF the key switch of the controller, and disconnect the AC power cable.

2.

Clean the laser emission port with an air duster

for optics, and wipe it lightly with a soft cloth. If a

contamination is severe, use a soft cloth immersed in

ethanol to wipe it.

ワㄐㄕㄊㄆ

• Do not wipe the protection glass of laser emission port strongly, or

touch it with a sharp pointed object. Laser marker might become

faulty.

WARNING

• Never use an inflammable air duster. The laser beam may ignite the gas,

resulting in fire.

Soft cloth

Protection glass

ME-LPM-SSM-10

Summary of Contents for LP-M Series

Page 16: ...16 MEMO ME LPM SSM 10...

Page 27: ...27 Chapter 1 Specification ME LPM SSM 10...

Page 37: ...37 Chapter 2 Preparation ME LPM SSM 10...

Page 69: ...Chapter 3 Connection for External Control ME LPM SSM 10...

Page 128: ...Chapter 4 Maintenance ME LPM SSM 10...

Page 148: ...Troubleshooting ME LPM SSM 10...

Page 169: ...Index ME LPM SSM 10...

Page 172: ...172 MEMO No 9000 0066 34V ME LPM SSM 10...

Page 173: ...No 9000 0066 34V...