3-3-60

1AH

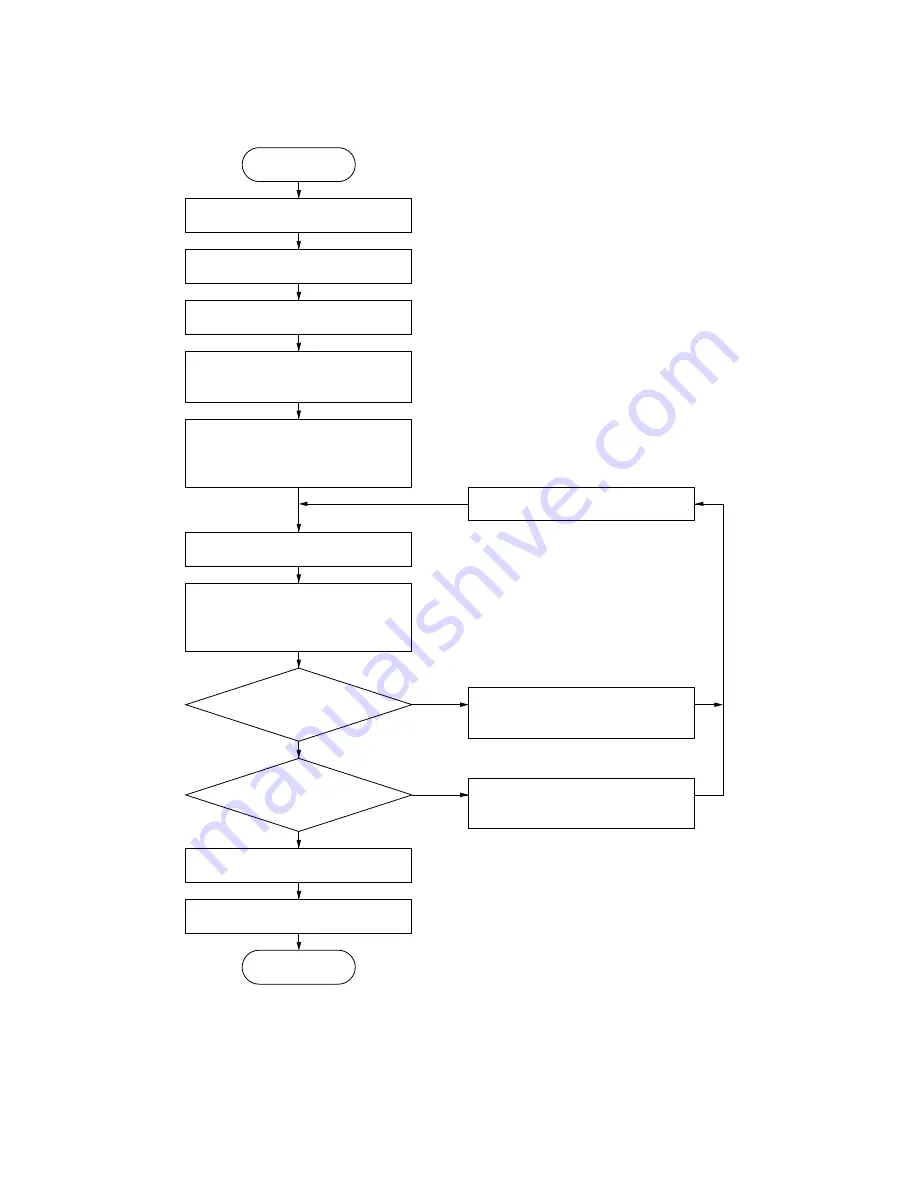

(10-1) Adjusting the exposure amount for enlargement mode (200%)

Procedure

Is the image

abnormally light?

Is the image

abnormally dark?

No

No

Yes

Yes

The copier enters ready mode.

· · · · · · ·

· · · · · · ·

The new setting is stored.

The current setting is displayed.

Select mode 1 with the exposure

adjustment keys.

Decrease the setting with the zoom

key.

Increase the setting with the zoom

key.

Press the print key to make a test

copy. (A test copy is made at

200%)

Place the NTC on the contact

glass and ensure there is A3/11"

×

17" paper present.

Press the print key.

Enter simulation mode.

Enter 29 with the numeric keys.

Press the print key.

Press the interrupt key.

Start

* Setting range: 102~242

Reference: 200

* Increasing the value makes the image

lighter, and decreasing it makes the im-

age darker.

End

Press the stop/clear key.

Exit simulation mode.

Summary of Contents for DC-2060

Page 1: ...SERVICE MANUAL Published in Oct 99 841AH110 DC 2060 2560 DC 2060 2560...

Page 2: ...Service Manual DC 2050 2560...

Page 4: ......

Page 13: ...1AH MCE THEORY AND CONSTRUCTION SECTION I I Theory and Construction Section...

Page 14: ...1AH 1 1 Specifications 1 1 1 Specifications DC 2560 1 1 1 1 1 4 Specifications DC 2060 1 1 4...

Page 24: ......

Page 30: ...1AH 1 3 6 1 2 3 4 5 6 7 8 9 0 1 3 3 Drive system Figure 1 3 6 Drive system copier...

Page 82: ...1AH MCE ELECTRICAL SECTION II II Electrical Section...

Page 83: ...1AH 2 1 Electrical Parts Layout 2 1 1 Electrical parts layout 2 1 1...

Page 84: ......

Page 94: ......

Page 105: ......

Page 124: ...1AH MCE III Set Up and Adjustment Section III SET UP AND ADJUSTMENT SECTION...

Page 126: ......

Page 151: ......

Page 177: ...1AH This page is intentionally left blank...

Page 185: ...1AH This page is intentionally left blank...

Page 209: ......

Page 259: ...3 3 50 1AH Figure 3 3 59 Secondary mirror inclination adjustment screw Secondary mirror...

Page 351: ......

Page 357: ......