DRAFT

C-2

Notation of the service manual

A. Product name

In this manual, each of the products is described as follows:

B. Brand name

The company names and product names mentioned in this manual are the brand name or

the registered trademark of each company.

C. Feeding direction

• When the long side of the paper is parallel with the feeding direction, it is called short

edge feeding. The feeding direction which is perpendicular to the short edge feeding is

called the long edge feeding.

• Short edge feeding will be identified with [S (abbreviation for Short edge feeding)] on the

paper size. No specific notation is added for the long edge feeding.

When the size has only the short edge feeding with no long edge feeding, [S] will not be

added to the paper size.

<Sample notation>

(1) magicolor 1600W/magicolor 1650EN

Main body

(2) Microsoft Windows NT 4.0:

Windows NT 4.0 or Windows NT

Microsoft Windows 2000:

Windows 2000

Microsoft Windows XP:

Windows XP

Microsoft Windows

V

ista:

Windows

V

ista

When the description is made in combination of the OS’s mentioned above:

Windows NT 4.0/2000

Windows NT/2000/XP/

V

ista

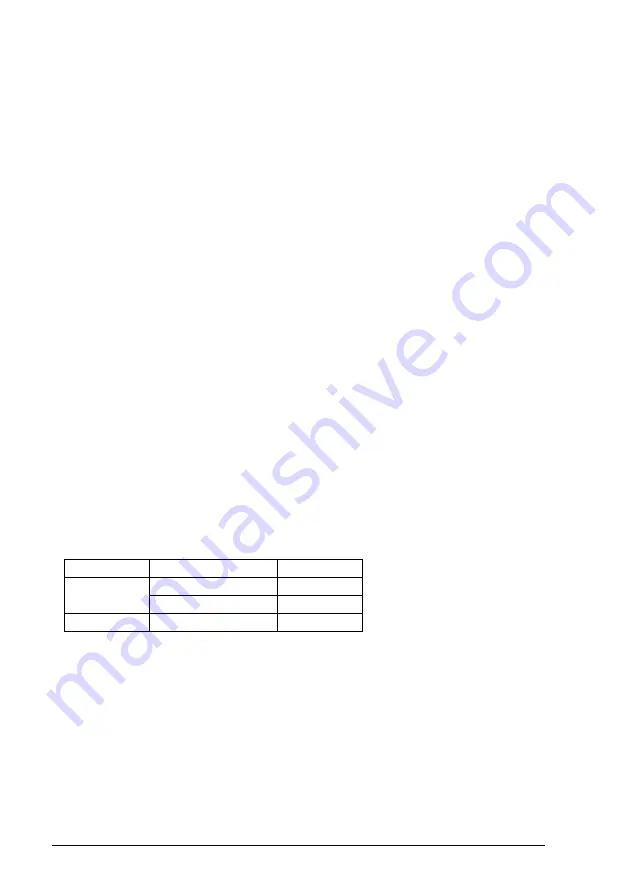

Paper size

Feeding direction

Notation

A4

Long edge feeding

A4

Short edge feeding

A4S

A3

Short edge feeding

A3

Summary of Contents for bizhub C35

Page 1: ...DRAFT SERVICE MANUAL 2010 02 2010 02 Ver 1 0 Ver 1 0 FIELD SERVICE ...

Page 3: ...DRAFT ii Blank Page ...

Page 28: ...DRAFT SERVICE MANUAL 2010 02 Ver 1 0 FIELD SERVICE Main body ...

Page 227: ...DRAFT 11 FAX PROTOCOLS Field Service Ver 1 0 Feb 2010 188 ADJUSTMENT SETTING Blank Page ...

Page 301: ...DRAFT 17 IC protector Field Service Ver 1 0 Feb 2010 262 Blank Page ...

Page 314: ...DRAFT SERVICE MANUAL 2010 02 Ver 1 0 FIELD SERVICE Lower Feeder Unit PF P08 ...

Page 317: ...DRAFT Lower Feeder Unit OUTLINE MAINTENANCE Field Service Ver 1 0 Feb 2010 ii Blank Page ...