10 Designation of assembly groups

C 1200

1. Two-piece discharge flap

2. 12 V electromotor for two-piece flap

3. Foldable discharge chute

4. Hydr. turntable (140°) chute

5. Hydr. connection for double spool valve

6. 12 Volt plug

7. Readjustable disc wheel 1180 rpm

12 chopping knives with wolfram layer

8. Sharpening mechanism

9. Smooth roller

10. Precompression roller with spring tension

11. Intake roller right

12. Intake roller left

13. Intake drum

14. Intake drum bearing

15. Cutting rotor – 1.25 m

16. Stalk lifter right

17. Middle prongs

18. Stalk lifter left

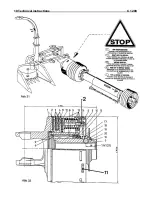

19. PTO shaft W 2400

20. Connection (serie 1 3/8”) for 1000 rpm PTO 150 HP

21. Slip clutch K 92/4 – T 1350 Nm

22. 3 point hitch Cat. II adjustable

23. Top link Cat. II adjustable

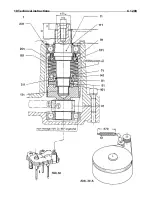

24. Angle gear 1 with FRONT and REAR connection

25. Angle gear 2 in swiveldrive

26. 3 point hitch frame

27. Hitch (not for heavy weights)

28. PTO shaft between the gear cases

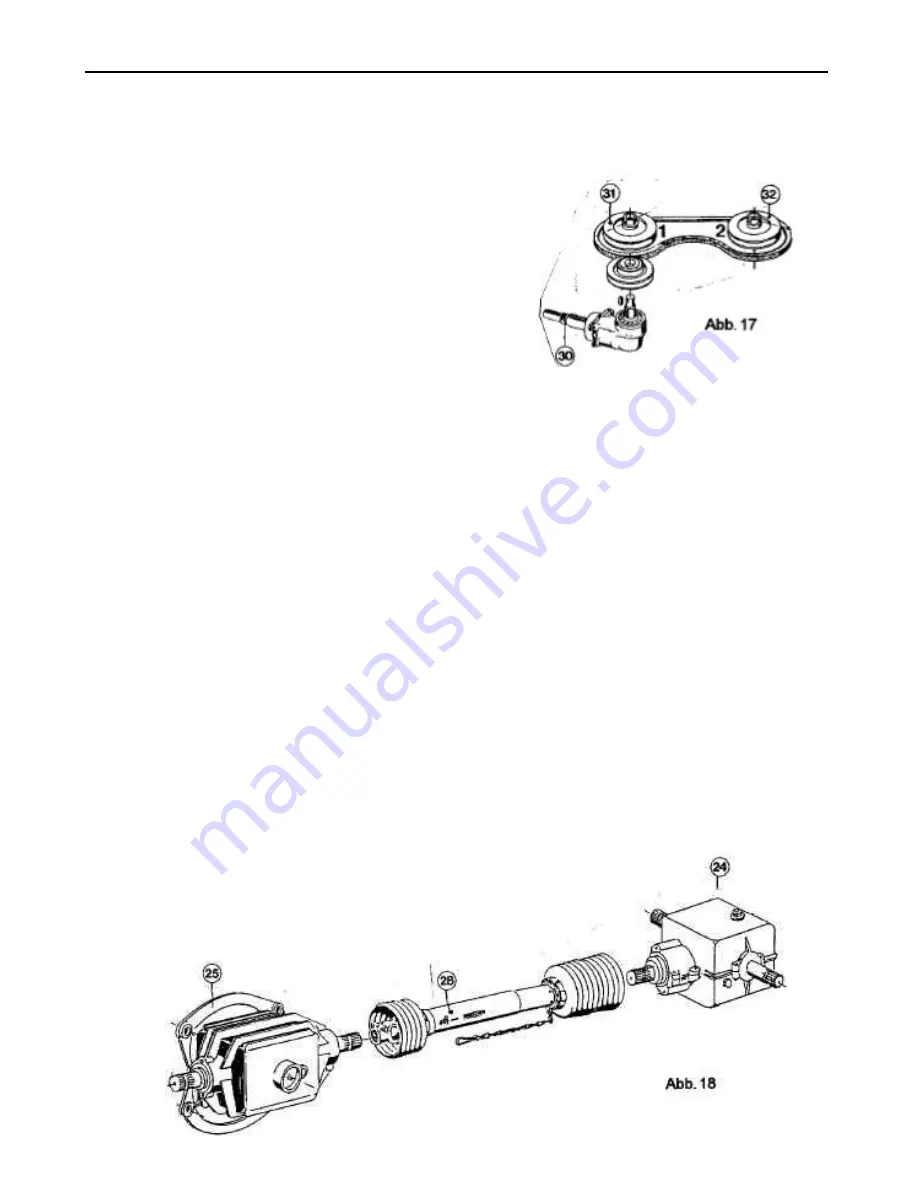

29. V-belt power with free running clutch

30. Angle drive on flywheel cutting disc

31. Changeable V-belt disc for chop length adjustment

32. Changeable V-belt disc for chop length adjustment

33. Automatic overload clutch

34. Locking pin

35. Double side usable shear bar

36. Stripper for smooth roller

37. Precompression roller housing

38. Gearing 4

39. Tension spring for precompression roller 10

40. Changeable crushing plate

41. Crusher plate for refining

42. Support wheel SR 13 = optional

43. Fixed stalk lifter tips for down crops

Summary of Contents for Champion C 1200

Page 13: ...10 Designation of assembly groups C 1200 ...

Page 15: ...12 Champion harvesting technology C 1200 ...

Page 17: ...19 Technical instructions C 1200 ...

Page 19: ...19 Technical instructions C 1200 ...

Page 29: ...30 Operating instructions C 1200 ...

Page 42: ...32 2 Blade rotor C1200 Installation position ...

Page 45: ...35 Greasing chart C 1200 ...

Page 47: ...35 Greasing chart C 1200 ...

Page 48: ...35 Greasing chart C 1200 ...

Page 51: ...38 Maintenance and inspection C 1200 ...

Page 53: ...38 Maintenance and inspection C 1200 ...