1 Safety instructions

C 1200

Safety and accident prevention regulations

1.

Do not allow anyone to stay in the intake area of the machine.

2.

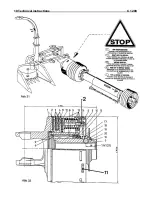

The sharpening device may only be operated with the housing of the flywheel cutting disc closed. When

operating the mechanism, stand at the side of the machine. Use protecting spectacles.

3.

Never attempt to feed the crop into the machine with your hands or feet.

4.

Whenever working on the forage harvester, switch off the PTO and stop the tractor engine.

5.

Before traveling on public roads always fold the guard frame over the stalk lifter.

6.

Never open the housing of the flywheel cutting disc while the machine is running. DANGER! The cutting disc

will continue to rotate even if the machine is switched off.

7.

Make certain the cutting knives are all tightened firmly.

8.

Always connect the PTO shaft coupler with care.

9.

Keep the PTO shaft guards in good condition and prevent the guard tubes from rotating by attaching the

provided safety chains.

10. Never cut rings from the guard cones of the PTO shaft.

11. Before carrying out any work under the machine, same has to proposed safely.

12. When traveling on public roads the discharge chute has to be positioned in such a way that is does not project

beyond the tractor or the implement, neither to the side nor to the rear.

13. Always comply with the lightening regulations in force of your country.

14. Do not allow anyone to stay in the slewing range of the discharge chute while cutting disc is rotating.

15. Front attachments may only be uncoupled on a level area.

16. Relieve all pressures before disconnecting hydraulic lines. Report immediately to a doctor in case of injury by

hydraulic oil forced out under high pressure.

17. The use of an appropriate ear protection is recommended.

18. Before tracing a foreign object, switch off all drive mechanisms, stop the engine and wait for all moving parts

to stop.

19. The machine height must not exceed 4.3m to avoid touching power lines.

20. The hitch is not designed for supported any additional load.

21. All controls of the machine must be positioned on the tractor mudguard within the operator’s reach.

22. It may be necessary to install front ballast weights to ensure adequate steering capabilities of the tractor.

When installing ballast weights, do not exceed the permissible axle load.

23. Do not allow anyone to stay in the slewing range of the machine. Check that the machine id in a horizontal

position when swinging round. Failure to do so may cause the machine to swing round due to its weights

when the locking mechanism is released. Special care should be taken when operating on a slope.

24. The hydraulic system is under high pressure. All damages or deteriorated hoses have to be replaced

immediately. In any case the hoses and hydraulic lines have to be replaces every six years.

25. Do not exceed the permissible hydraulic pressure of 210 bar.

26. Use only genuine KEMPER spare parts.

Summary of Contents for Champion C 1200

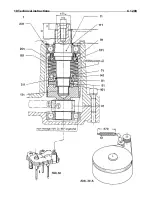

Page 13: ...10 Designation of assembly groups C 1200 ...

Page 15: ...12 Champion harvesting technology C 1200 ...

Page 17: ...19 Technical instructions C 1200 ...

Page 19: ...19 Technical instructions C 1200 ...

Page 29: ...30 Operating instructions C 1200 ...

Page 42: ...32 2 Blade rotor C1200 Installation position ...

Page 45: ...35 Greasing chart C 1200 ...

Page 47: ...35 Greasing chart C 1200 ...

Page 48: ...35 Greasing chart C 1200 ...

Page 51: ...38 Maintenance and inspection C 1200 ...

Page 53: ...38 Maintenance and inspection C 1200 ...