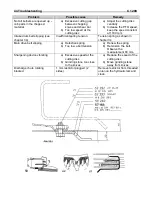

35 Greasing chart

C 1200

Servicing intervals

The indicated servicing intervals are calculated for normal operating

conditions. Before lubricating clean the grease nipples. Damaged grease

nipples have to be replaced. If a new grease nipple should not accept

grease, remove it and find the cause of blockage.

Caution!

Cleaning, lubricating and adjusting work may only be carried out with the

engine stopped. Wait for all machine components to be at a complete stop.

All lubricating and maintenance jobs have to be carried out before and after

every season.

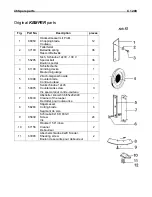

Symbols

=

Grease every 50 working hours

A = Oil drain plug

=

Grease every 100 working hours

E = Oil filler plug

=

Grease every day

L = Breather

=

1,5 liter transmission oil SAE 90

N = Grease nipple

=

Periodically grease all hinge points

P = Oil level check plug

=

Grease, semi fluid Aviaticum XRF

Greasing chart

1 = Feed roller – lower bearing

2 = Feed roller – lower bearing

3 = Precompression roller – lower bearing

4 = Pivot – top bearing

5 = Pivot – lower bearing

6 = Free wheel mechanism

7 = Intake drum – lower bearing

8 = Intake drum – top bearing

9 = Flywheel cutting disc – front bearing (grease nipple on gearbox)

10 = Flywheel cutting disc – rear bearing

11 = Grinding stone bearing

12 = Pivot discharge chute

13 = Main PTO

14 = Flywheel cutter – hub – shaft

15 = Flywheel cutter – hub – shaft

16 = PTO shaft between the gearboxes

17 = Optional equipment – crop divider 2 nipples

18 = Optional equipment – support wheel

19 = Swivel point chute

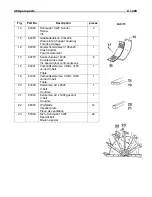

21 = Angle drive – flywheel cutting disc: 0.3 = Semi fluid grease XRF

22 = Spur gear – precompression roller: 1.0 = Semi fluid grease XRF

23 = Angle drive – main drive:

1.3 = SAE 90 Oil

24 = Angle drive – pivot:

0.5 = SAE 90 Oil

25 = Pendulum drive:

0.5 = Semi fluid grease XRF

Summary of Contents for Champion C 1200

Page 13: ...10 Designation of assembly groups C 1200 ...

Page 15: ...12 Champion harvesting technology C 1200 ...

Page 17: ...19 Technical instructions C 1200 ...

Page 19: ...19 Technical instructions C 1200 ...

Page 29: ...30 Operating instructions C 1200 ...

Page 42: ...32 2 Blade rotor C1200 Installation position ...

Page 45: ...35 Greasing chart C 1200 ...

Page 47: ...35 Greasing chart C 1200 ...

Page 48: ...35 Greasing chart C 1200 ...

Page 51: ...38 Maintenance and inspection C 1200 ...

Page 53: ...38 Maintenance and inspection C 1200 ...