38 Maintenance and inspection

C 1200

Daily

maintenance

•

remove husk and stem residues and earth from cutting disc and the

working range of the intake drums

•

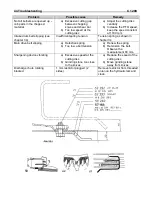

Check the cleaners for the knives under the feed mechanism (see

fig. 27). Blunt or incorrectly positioned cleaners will cause blockages

and expose the drive mechanism to unnecessary load.

•

Grind the knives of the flywheel cutting disc several times a day.

•

Check the M12 attaching bolts of the cutting knives using a torque

wrench. Correct tightening torque:

130 Nm

Note

: The standard tightening torques of 70 Nm will not be sufficient.

•

Adjust the cutting disc centrally in relation to the shear bar.

•

Even the knives have not been sharpened, the flywheel cutting disc

has to be readjusted twice a day.

•

Check all knives under the feed mechanism, especially after a

foreign object has been encountered.

•

Visual control of the parallelism of shear bar and cutting knives.

•

Lubricate the implement in accordance with the greasing chart.

•

Retighten all screws and bolts.

•

Retighten the wheel studs.

Weekly

maintenance

•

Retighten all attaching bolts of the cutting disc.

•

Check the shear bar of the cutting disc. Reverse the shear bar if

necessary.

•

Check the pivot and the angle drive.

•

Lubricate the implement in accordance with the greasing chart.

Annual

maintenance

•

Clean the machine and treat it with an anticorrosive agent.

•

Change the oil in the gearboxes – observe the oil quantity laid down

by the manufacturer.

•

Check all components for wear.

•

Order genuine spare parts in time.

•

Check the V-belt drive and the pivot.

•

Check the overload clutches of the PTO shaft.

•

Check all hydraulic lines and couplers.

•

Check the complete housing with feed- and precompression rollers.

Maintenance and

controls before

start of season

•

Read the operators manual again.

•

Grease all parts of the machine with required lubrication.

•

Retighten all screws and bolts-

•

Check the knives under the feed mechanism, the knives of the

flywheel cutting disc and the shear bar.

•

Tightening torques:

Special knife attaching bolt with

knurled bottom of the bolt head:

M12 = 130 Nm

Standard bolts:

M12 = 70 Nm

M16 = 180 Nm

M 18 = 250 Nm

M20 = 360 Nm

•

Check feed assisters on the intake drum and the divider points and

replace if necessary.

•

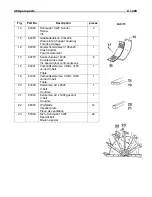

Foreign objects may cause damage or deformations in the area

where the stems are cut. It is therefore essential to check this area

periodically. Straighten deformed feed tines Z (see fig. 53).

Summary of Contents for Champion C 1200

Page 13: ...10 Designation of assembly groups C 1200 ...

Page 15: ...12 Champion harvesting technology C 1200 ...

Page 17: ...19 Technical instructions C 1200 ...

Page 19: ...19 Technical instructions C 1200 ...

Page 29: ...30 Operating instructions C 1200 ...

Page 42: ...32 2 Blade rotor C1200 Installation position ...

Page 45: ...35 Greasing chart C 1200 ...

Page 47: ...35 Greasing chart C 1200 ...

Page 48: ...35 Greasing chart C 1200 ...

Page 51: ...38 Maintenance and inspection C 1200 ...

Page 53: ...38 Maintenance and inspection C 1200 ...