33 Replacing bottom plate

C1200

Adjust the cracker plate to suit the type of the crop.

- Smooth plate for standard products

- Crushing plate for dry products

- By using the cracker plate, the maize corns are effectively ground to small

particles. This however requires a higher power input from the tractor.

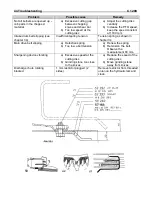

Dismantling of cracker plate

The grinding effect of the cracker plate

can be adjusted by placing washers

between the cracker plate and the

housing. The smaller the gap between

the blade wheel and the cracker plate,

the smaller the corns are chopped.

Remove the two M 10 x 70 mounting

screws.

Remove the cracker plate.

Re-mount in reverse order.

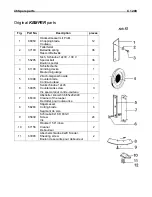

The outer cracker plate panel (3) can be

equipped with a smooth plate (1) or a

cracker plate (2).

When changing plates, ensure that the

supporting surfaces are clean.

Turning of cracker plate

The service life of the cracker plates can be prolonged by reversing their position

(items 1 + 2).

Summary of Contents for Champion C 1200

Page 13: ...10 Designation of assembly groups C 1200 ...

Page 15: ...12 Champion harvesting technology C 1200 ...

Page 17: ...19 Technical instructions C 1200 ...

Page 19: ...19 Technical instructions C 1200 ...

Page 29: ...30 Operating instructions C 1200 ...

Page 42: ...32 2 Blade rotor C1200 Installation position ...

Page 45: ...35 Greasing chart C 1200 ...

Page 47: ...35 Greasing chart C 1200 ...

Page 48: ...35 Greasing chart C 1200 ...

Page 51: ...38 Maintenance and inspection C 1200 ...

Page 53: ...38 Maintenance and inspection C 1200 ...