Models

Revision 03-2012

24

Toucan 1210

Toucan 1310

HYDRAULIC SYSTEM

3

3

Disassembly :

1- Remove the plastic nuts holding the coils.

2- Remove the O-rings and the coils.

3- Remove the poletubes using adequate tooling

(Ref. 990005), (Torque to unscrew : 13 to 33

N.m).

4- Remove the spring guides and drive the spool

out of the sleeve.

Inspection :

1- Clean all parts with an appropriate solvent and

dry with compressed air.

2- Check the spool surfaces are not scratched.

3- Check the axial and radial holes at each end

of the spool are not blocked.

NOTE

If the spool is scratched or if the holes are

blocked, the spool AND the sleeve must be

replaced.

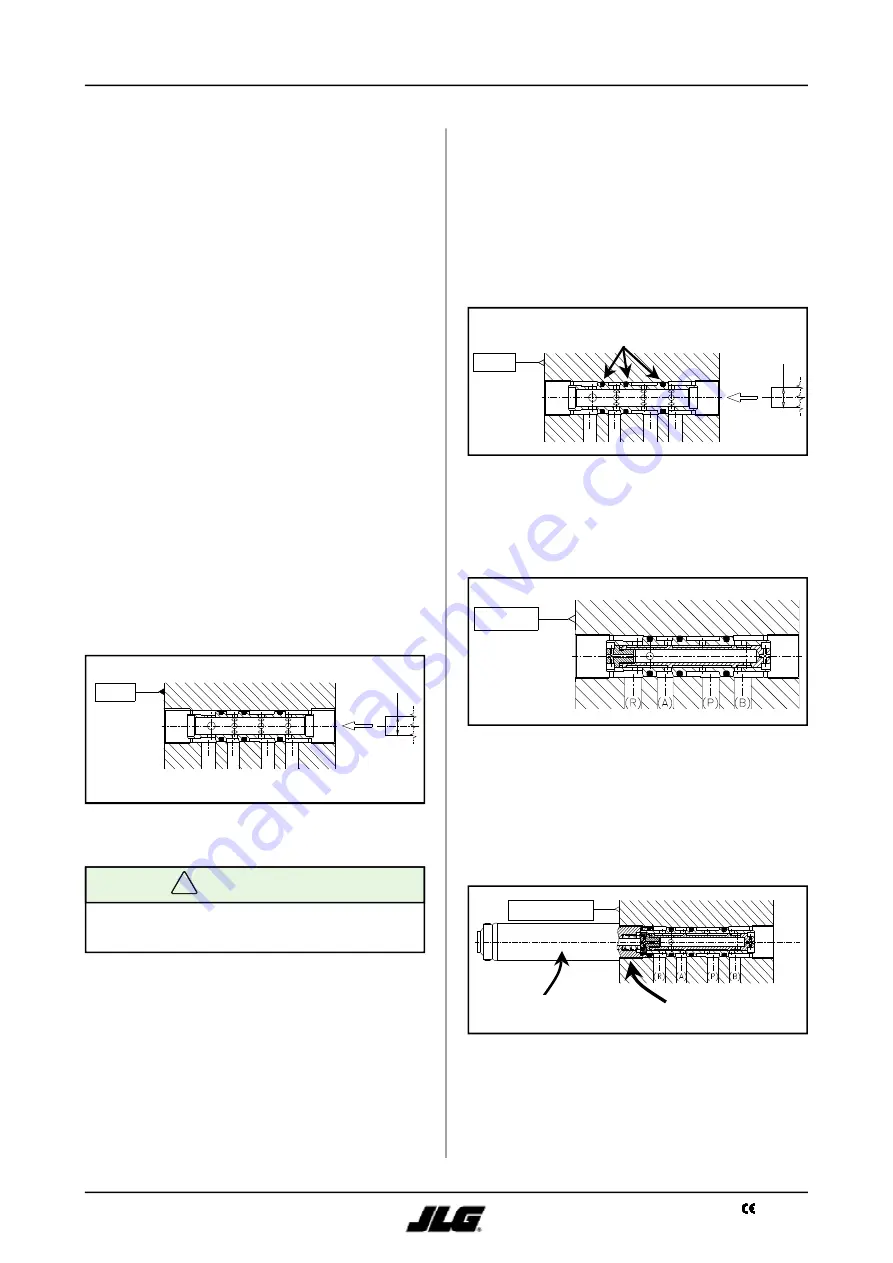

If the spool and the sleeve have to be replaced, drive

the sleeve out of the manifold using an appropriate

mandrel in the direction indicated in the drawing below

:

Assembly :

Never interchange spools and sleeves. All

components must be clean before assembly.

1- Check for burrs that could damage O-rings

during the installation of the sleeve.

2- Install the O-rings on the sleeve.

NOTE

Ensure the seals are not stretched and the

grooves damaged during assembly.

3- Lubricate the seals before sleeve installation

(MILLCOT K320 or equivalent).

4- Insert the sleeve in the manifold using an

appropriate mandrel in the direction indicated

in the drawing below :

5- Lubricate the spool with clean hydraulic oil.

Slide the spool into the sleeve as indicated

below. Ensure the spool slides freely inside the

sleeve.

6- Install the spring guide on face B side as

indicated in the drawing below. Install the spring

in the poletube. Install the poletube on the

manifold using Loctite® 245. Torque the

poletube to 10 - 12 N.m using adequate tooling

(Ref. 990005).

NOTE

The thread on the poletube must be free from

oil or grease before the glue is applied.

(B)

(P)

(A)

(R)

Face B

Mandrel

Ø

9

,8

(B)

(P)

(A)

(R)

Face B

Mandrel

Face B

Face B

Torque value

10 to 12 N.m

LOCTITE 245

Millcot K320

or equivalent

0

-0

,2

Ø

9

,8

0

-0

,2

!

CAUTION