121

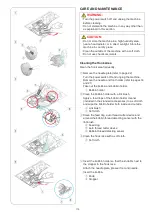

Problem

Cause

Reference

The machine is

noisy.

1. Thread is jammed in the hook area.

2. The feed dog is packed with lint.

Page 115.

Page 115.

The needle thread

breaks.

1. The needle thread is not threaded properly.

2. The needle thread tension is too tight.

3. The needle is bent or blunt.

4. The needle is inserted incorrectly.

5. The thread is too heavy for the needle.

6. The needle thread was not set in the thread holder when

embroidery sewing started.

Pages 27-28.

Page 53.

Page 21.

Page 21.

Page 21.

Page 40.

The bobbin thread

breaks.

1. The bobbin thread is not threaded properly in the bobbin holder.

2. Lint has collected in the bobbin holder.

3. The bobbin is damaged and does not turn smoothly.

Page 26.

Page 115.

Replace the bobbin.

The needle breaks. 1. The needle is inserted incorrectly.

2. The needle is bent or blunt.

3. The needle clamp screw is loose.

4. The needle thread tension is too tight.

5. The needle is too fine for the fabric being sewn.

Page 21.

Page 21.

Page 21.

Page 53.

Page 21.

Visual touch screen

is not clear.

1. The brightness of the visual touch screen is not adjusted properly. Page 98.

Skipped stitches.

1. The needle is inserted incorrectly.

2. The needle is bent or blunt.

3. The needle and/or threads are not suitable for the fabric being

sewn.

4. A blue needle is not being used for sewing stretch, very fine or

synthetic fabrics.

5. The needle thread is not threaded properly.

6. The needle is defective (rusted, burr on needle eye or tip).

7. The embroidery hoop is not set properly.

8. The fabric is not stretched tightly enough on the embroidery

hoop.

9. A purple needle is not being used for sewing thick fabrics, denims

and across the hem.

Page 21.

Page 21.

Page 21.

Page 21.

Pages 27-28.

Change the needle.

Page 40.

Pages 38-39.

Page 21.

Seam puckering.

1. The needle tension is too tight.

2. The needle thread or the bobbin thread is not threaded correctly.

3. The needle is too heavy for the fabric being sewn.

4. The fabric is not stretched tightly enough on the embroidery

hoop.

5. A stabilizer is not attached to the back of the fabric for dense

embroidery pattern designs.

Page 53.

Pages 26-28.

Page 21.

Pages 38-39.

Page 36.

The machine does

not run.

1. The machine is not plugged in.

2. A thread is caught in the hook race.

3. The foot control is plugged in for sewing embroidery.

Page 9.

Page 115.

Unplug the foot control

and use start/stop

button.

Troubleshooting (Embroidery)