3

• DOK-POWER*-TVD*1.3****-ANW1-EN-E1,44 • 02.97

Table of Contents

Table of Contents

1.

Construction of INDRAMAT Modular A.C. Drive System

7

1.1.

Main functions of the TVD 1.3 .......................................................... 8

2.

Range of Applications

9

2.1

Functional power features of the TVD 1.3 .....................................10

2.2.

Power ratings of the TVD 1.3 ......................................................... 11

2.3.

Overload Capabilities of the TVD 1.3 ............................................. 11

2.4.

Technical Data - TVD 1.3 ...............................................................12

2.5.

Ambient Conditions ........................................................................13

3.

Electrical Connections – Installation Guidelines

14

3.1.

Interconnect diagram TVD 1.3 with NAM 1.3 ................................. 15

3.2.

TVD 1.3 interconnect diagram with individual,

additional components ................................................................... 16

3.3

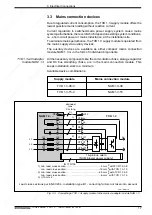

Mains connection devices ..............................................................17

3.4.

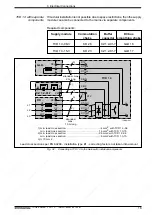

Mains connection to power circuits ................................................ 19

3.5.

Fuse protection for direct mains connection .................................. 21

3.6.

Mains supply earthing requirements ..............................................21

3.7.

Commutation choke .......................................................................23

3.8.

DC bus circuit .................................................................................23

3.9.

DC bus smoothing choke ...............................................................24

3.10. Additional DC bus capacitance ......................................................24

3.11. Bridge circuit capacitance ..............................................................24

3.12. Additional bleeder module TBM .....................................................25

3.13. External bleeder resistor ................................................................26

3.14. Supply to electronics and blower ................................................... 27

3.15. Electronics supply buffer capacitance ............................................28

3.16. Electronics supply and signal exchange

connections .................................................................................... 29

3.17. Residual current operated devices ................................................ 30

3.18. Control cabinet testing ................................................................... 31

3.19. Mounting the TVD 1.3 into the control cabinet ............................... 31