16

• DOK-POWER*-TVD*1.3****-ANW1-EN-E1,44 • 02.97

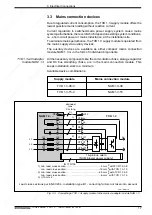

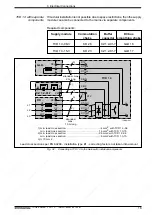

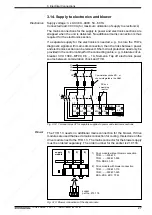

3.2. TVD 1.3 interconnect diagram with individual,

additional components

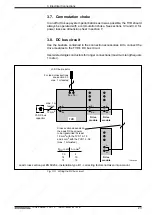

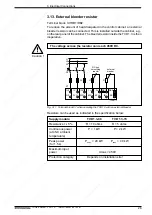

3. Electrical Connections

L-

L+

+ -

2

X 7

R2

X16

UD

BB

+15V

0VM

-15V

+24V

0VL

UESS

shield

Bb1

UD

BVW

TVW

ZKS

ZKS

OFF

OFF

ON

ON

+15VM

0VM

-15VM

3xAC (380 - 480) V

(50 - 60) Hz

PE

L3

L2

L1

power

supply

electronics

supply

2U1

2V1

2W1

1U1

1V1

1W1

EPU+

EPU -

PE

K1

1

2

3, 4

5, 6, 7, 8

9, 10

11, 12

13, 14

15

16

NCB

X 2

X 3

X 4

X 5

X 12

X 9

X1

Q1

K1

K1

1L+

2L+

EB

IB

RB1

RB2

1

2

3

4

5

6

1

2

3

4

5

6

7

8

1

2

3

4

C1

R1

EB

C2

TBM

U1

W1

V1

U2

W2

V2

1

X7/EB

L-

L+

L2

X 8

X 7

+24V 0V

X15

12

TVD 1.3

Power supply module for direct connection

- with built-in bleeder

- with regulated DC bus

central grounding point

for all drive modules

Power

supply

for

AC

drives

and/or

main

spindle

drives

DC 300V

conductor rails

Electronics

power

supply

,

signal

exchange,

16-pin

bus

connection

ready

bleeder prewarning

temp. prewarning

acknowledge power of

f

acknowledge power on

ZKS

OFF

ON

Options

R1 - bleeder

, ext. mounting

R2 - auxiliary bleeder module

TBM

C1 - additional electronics backup

C2 - additional power backup

max. 2

A

NC controlled braking

max. 100 mA

power voltage ok

BR1 - bridge for switching

the bleeder

C3 - Buf

fer capacitance

L1 - DC bus smoothing reactor

L2 - commutating reactor

T

erminal diagram for Supply Module TVD 1.3 with Individual Components

with 380 ... 480V mains connection for power and electronics - internal power switch

1

2

3

4

5

6

+24V

0VL

7

8

BR1

- +

for TBM

with

DC 24V blower

power source

TVD/KompAnschlpl

L1

P

N

P

N

C3

shield

Fig. 3.2:

Interconnect diagram of TVD 1.3 supply module with individual additonal

components