51

• DOK-POWER*-TVD*1.3****-ANW1-EN-E1,44 • 02.97

6. Troubleshooting

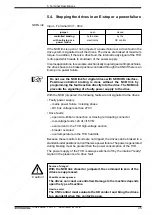

Danger from voltage

carrying parts

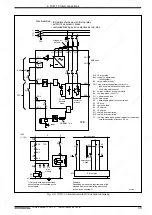

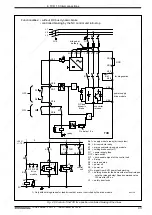

Dangerous voltage can occur at the following connections:

- At all connections to the power supply and its associated chokes and

capacitors, and especially at connections to mains 1U1, 1V1, 1W1 and 2U1,

2V1, 2W1, as well as X13 und X14 of the blower.

- At the drive modules, motor and connections to the motor.

Source of danger:

Electrical voltages of up to 700 V!

Possible consequences:

Danger to life and limb and property damage! Working on the range

of energized components can lead to fatal injuries. This particularly

applies to the supply modules and its related chokes, capacitors and

fuses as well as drive modules, motor and motor connections.

How to avoid:

Only trained and qualified electrical personnel may be permitted to

work on the machine.

Turn off all power to the installation for all work in the hazardous area.

Lockout the installation so that power cannot be turned on.

Prior to starting work, use measuring devices to check whether the

components of the machine are still energized (e.g., capacitors and

so on). Wait the discharge time of the DC bus which is approximately

five minutes!

Use only that measuring and testing equipment that is suitable and

appropriate to the application.

Do not run motors. Voltage is present at the motor connections if the

motor is in motion. Vertical axes must be secured against movement

if the machine is switched off.

Insert protective caps into cables or open cable ends of power plug-

in connectors when replacing drive components.

Do not power up until the all safety shrouds and devices for supply and drive

modules are mounted back into place.

Danger !