Service Guide

D-4

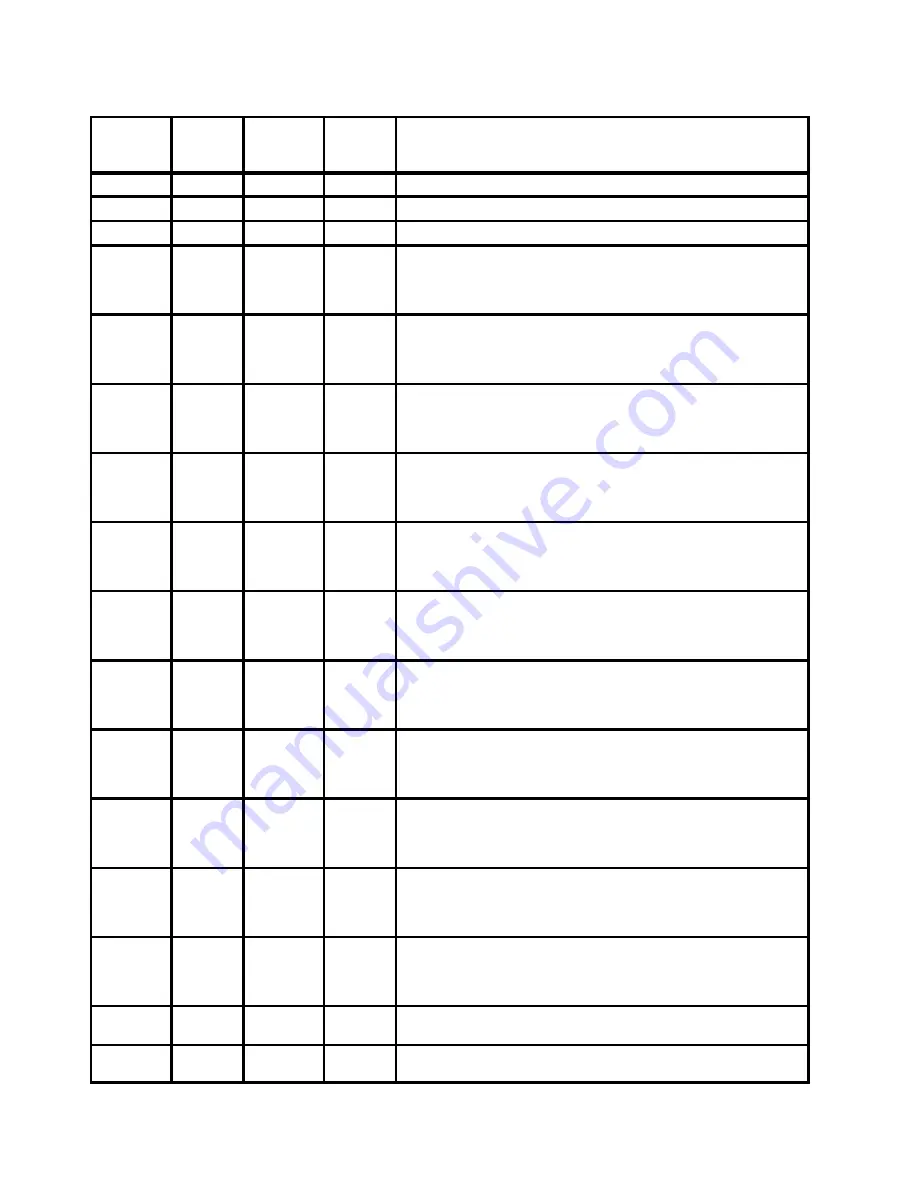

Error

Number

Source

Failing

Function

Codes

Failure

Percent

(%)

Description

401-140

K

all boards

Description: Bad VPD Board.

401-141

K

all boards

Description: No Board present.

401-142

K

all boards

Description: No coherent configuration on board.

401-150

K

C59

C61

C63

C88

40

20

20

20

Description: Asynchronous lines access.

Line Sx: register error

Action: Use MAP 0210.

401-151

K

C59

C61

C63

C88

40

20

20

20

Description: Asynchronous lines access.

Line Sx: status register error.

Action: Use MAP 0210.

401-152

K

C59

C61

C63

C88

40

20

20

20

Description: Asynchronous lines access.

Asynchronous line buffer exchange error.

Action: Use MAP 0210.

401-153

K

C59

C61

C63

C88

40

20

20

20

Description: Asynchronous lines access.

Line Sx: register error on bit i.

Action: Use MAP 0210.

401-160

K

C59

C61

C63

C88

40

20

20

20

Description: BPP ext. Loop back. Status register error.

Action: Use MAP 0210.

401-161

K

C59

C61

C63

C88

40

20

20

20

Description: BPP ext. Loop back. Error bit i#0.

Action: Use MAP 0210.

401-162

K

C59

C61

C63

C88

40

20

20

20

Description: BPP ext. Loop back. Error bit i#1.

Action: Use MAP 0210.

401-170

K

C59

C61

C63

C88

40

20

20

20

Description: Printer error: not selected.

Action: Use MAP 0210.

401-171

K

C59

C61

C63

C88

40

20

20

20

Description: Printer error: end of paper.

Action: Use MAP 0210.

401-172

K

C59

C61

C63

C88

40

20

20

20

Description: Printer on error.

Action: Use MAP 0210.

401-173

K

C59

C61

C63

C88

40

20

20

20

Description: Printer time out, always busy.

Action: Use MAP 0210.

401-180

K

C59

Modem

20

80

Description: DIAL-OUT test. Dial out not authorized.

401-181

K

C59

Modem

20

80

Description: DIAL-OUT test. Quick on Call Service not

subscribed.

Summary of Contents for 7015-R30

Page 1: ...7015 Models R30 R40 and R50 CPU Enclosure Installation and Service Guide...

Page 10: ...x Service Guide...

Page 14: ...xiv Service Guide...

Page 34: ...1 20 Service Guide...

Page 214: ...6 10 Service Guide Detail 5 CPU Module 2 of 3 26 27 29 30 31 32 33 34 28 35...

Page 216: ...6 12 Service Guide Detail 6 CPU Module 3 of 3 36 37...

Page 252: ...B 8 Installation and Service Guide...

Page 288: ...Service Guide D 30...

Page 299: ......