Main Menu

Communications

Menu Overview

22

900 Control Station User Guide

Revision 9

May 2014

Communications

Menu Overview

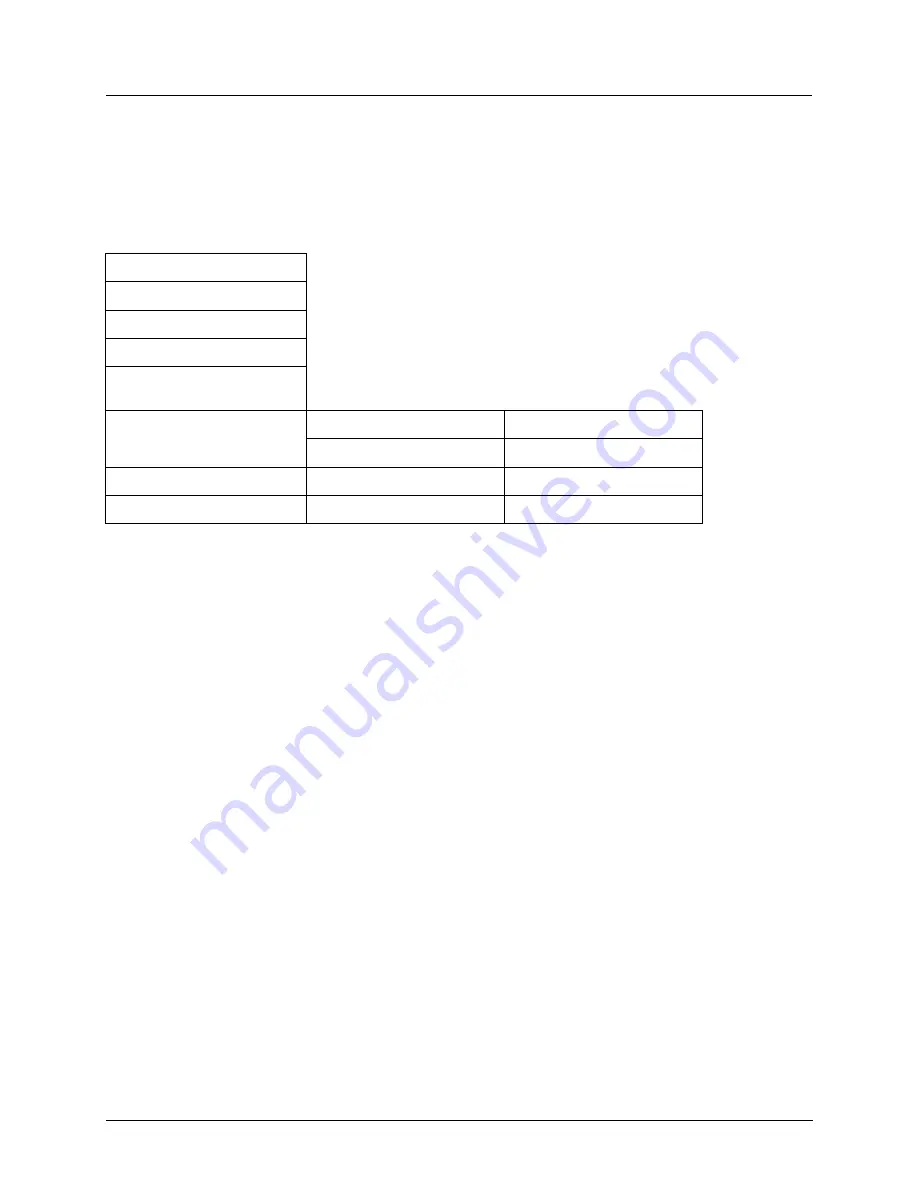

Menu

Submenu

Serial Port S1 (p. 22)

Serial Port S2 (p. 22)

Ethernet Port E1 (p. 27)

Ethernet Port E2 (p. 27)

Expansion Port

Communications (p. 29)

Modbus Slave Devices (p. 31)

Modbus Slave Device

n

Modbus Slave

n

Status

Modbus/TCP Slave Device

n

Modbus/TCP Slave

n

Status

Host Connections (p. 32)

Host Connection

n

Host Connection

n

Status

Peer Connections (p. 33)

Peer Connections

n

Peer Connection

n

Status

NOTE:

The 15" control station can be programmed using only the Ethernet, serial and compact flash card.

The 900CS15's USB programming port conflicts with today’s PCs so it's advisable to use Ethernet ports for

configuration changes. This problem has been observed only with the 15" control station; the 10" control

station has not shown any problems with its USB ports.

Serial Port S1/S2

The Serial Port S1 and Serial Port S2 screens both show Statistics (Table 6) and Settings (Table 8) for those

controller serial ports.

Table 9 shows the relationship between the setup parameters and each protocol.

The controller’s Serial Port S1 can be set-up as an ELN Configuration port, a Modbus Master port, or a

Modbus Slave port. The ELN protocol allows the controller to communicate with the Process Control

Designer package on the PC using the proprietary ELN protocol. The Modbus Master protocols allow the

controller to act as a Modbus Master, retrieving data from other instruments that have been configured as

Modbus slave devices. The three Modbus Slave protocols allow the controller to act as a slave to various

host devices, including a PC running HC Designer.

The information presented in Table 6 and Table 9 also applies to Serial Port S1 when a Redundant

Controller is used.