PART ONE - INTRODUCTION

SECTION 1 - GENERAL INFORMATION

Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN)

Rev. 1-201

18

1.3 Retained

Configuration Values

1.4 Analyzer

Serial Number

1.5 EMI/RFI Immunity

All user-entered configuration values are retained indefi-

nitely, even if power is lost or turned off. The non-volatile

analyzer memory does not require battery backup.

A label with the analyzer model number, serial number,

build date, and other items is located on top of the enclo-

sure.

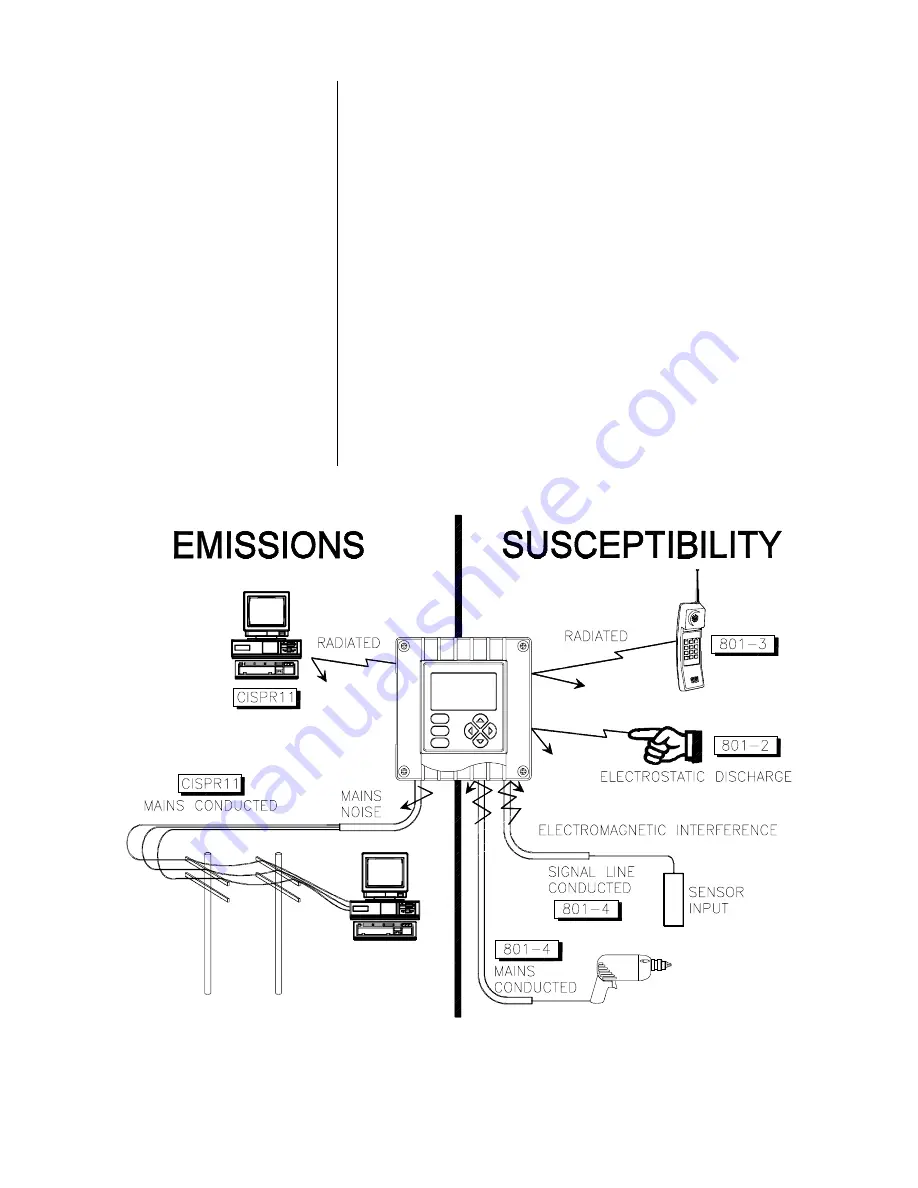

The analyzer is designed to provide protection from most

normally encountered electromagnetic interference. This

protection exceeds US standards and meets European

IEC 801-series testing for electromagnetic and radio fre-

quency emissions and susceptibility. Refer to Figure 1-1

and the specifications in Section 2.1 for more information.

FIGURE 1-1 EMI/RFI Immunity Diagram